Method for winding cross-wound spools with precision winding on a two-for-one twisting machine

A bobbin and bobbin technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as damage to the quality of cross bobbins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

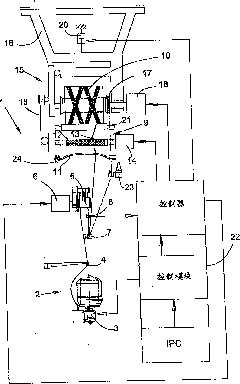

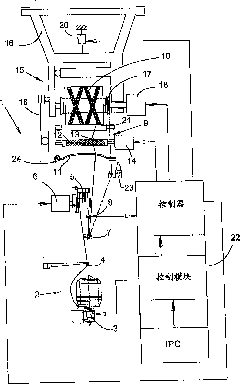

[0021] The present invention will be described in more detail below with reference to the embodiments shown in the drawings.

[0022] figure 1 The single figure in is a schematic diagram of the structural principle of the twisting station 1 of a two-for-one twisting machine with a plurality of similar twisting stations, with the aid of which the method of the invention is described. The twisting station 1 of the two-for-one twisting machine comprises a twisting spindle 2 driven by a single-motor spindle drive 3 . The twisting spindle 2 comprises bobbins, bobbin brakes, storage discs on the twisting plate and replaceable yarn guides, such as deflection elements on the storage discs and eyelets on the bobbin brakes, the structure of which guides on their surface And its quality aspect can be adapted to the yarn to be treated. The twisted yarn in the twisting spindle 2 is supplied to a first yarn guide 4 of a feeding device 5 driven by a drive 6 , which draws the yarn out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com