Ultra-pure gadolinium oxide and electrochemical reduction fully-closed type extracting production process thereof

A gadolinium oxide, ultra-high technology, applied in the improvement of process efficiency, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of long production cycle, low output, unstable rare earth impurity content, etc. Low impurity content and good reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Reagent parameters

[0044] (1) Composition of raw materials:

[0045]

[0046] (2) Feed liquid concentration 0.3mol / L acidity PH=1.5

[0047] (3) Extractant volume ratio 30%P 507 Extractant, 15%P 204 Extractant and 55% sulfonated kerosene

[0048] (4) Caustic soda 8mol / L

[0049] (5) Hydrochloric acid 2mol / L, 5mol / L, 4mol / L

[0050] (6) washing water deionized water

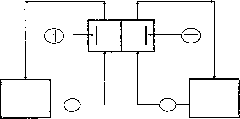

[0051] (2) RE / Gd extraction and separation:

[0052] enter:

[0053] Flow ratio V 有机相 :V 料液 :V 洗酸 =1:0.2:0.05

[0054] Stages Extraction section + washing section multi-stage composition

[0055] output:

[0056] Extraction and separation to obtain low-samarium-rich gadolinium material (organic phase)

[0057] (3) Gd / RE extraction and separation:

[0058] The low-samarium gadolinium-rich material (organic phase) obtained by RE / Gd extraction and separation is used as a raw material, and the organic feed method is used for further extraction and separation.

[0059] enter:

[0060] F...

Embodiment 2

[0087] (1) Reagent parameters

[0088] (1) Composition of raw materials:

[0089]

[0090] (2) Feed liquid concentration 1.5mol / L acidity PH=2.5

[0091] (3) Extractant volume ratio 35%P 507 Extractant, 20%P 204 Extractant and 45% sulfonated kerosene

[0092] (4) Caustic soda 8mol / L

[0093] (5) Hydrochloric acid 2mol / L, 5mol / L, 4mol / L

[0094] (6) washing water deionized water

[0095] (2) RE / Gd extraction and separation:

[0096] enter:

[0097] Flow ratio V 有机相 :V 料液 :V 洗酸 =1:0.2:0.05

[0098] Stages Extraction section + washing section multi-stage composition

[0099] output:

[0100] Extraction and separation to obtain low-samarium-rich gadolinium material (organic phase)

[0101] (3) Gd / RE extraction and separation:

[0102] The low-samarium gadolinium-rich material (organic phase) obtained by RE / Gd extraction and separation is used as a raw material, and the organic feed method is used for further extraction and separation.

[0103] enter:

[0104] F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com