Spiral factory building

A workshop and spiral technology, applied in construction, industrial construction, building construction, etc., can solve the problems of reducing the qualified rate of products, affecting the processing accuracy of the station, and difficult to construct the inclined plane, so as to reduce the solid rotation time, improve the production efficiency, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

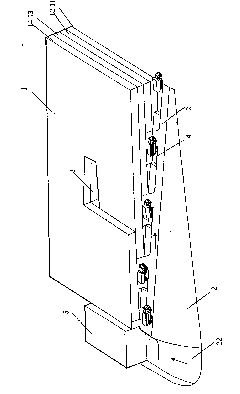

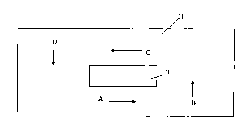

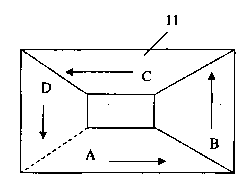

[0016] Combine below Figure 1 to Figure 5 The spiral plant construction of the present invention is described in further detail.

[0017] Such as figure 1 , in the present embodiment, factory building 1 is long 100m, wide 50m, and the whole roughly is rectangular parallelepiped shape, and it has four layers 11,12,13,14 altogether, also can have more layers according to demand, the middle of factory building 1 has long A gap 3 with a width of 20m and a width of 6m can be used to install elevators or central air conditioners or other equipment. There is a foundation 2 on one side of the factory building 1. There is a two-story building 5 on the foundation, which can be used as a heavy equipment factory building. The building 5 can be determined according to the specific required space. The other side of this factory building 1 has a slope road 21, and its road width 4m is used for making the transportation channel that truck delivers goods to each floor, and the low end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com