Heat dissipation-optimized LED (light-emitting diode) lamp and light fitting thereof

A technology of LED lamps and LED lamps, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of unreasonable design of heat sinks, high cost, large product size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

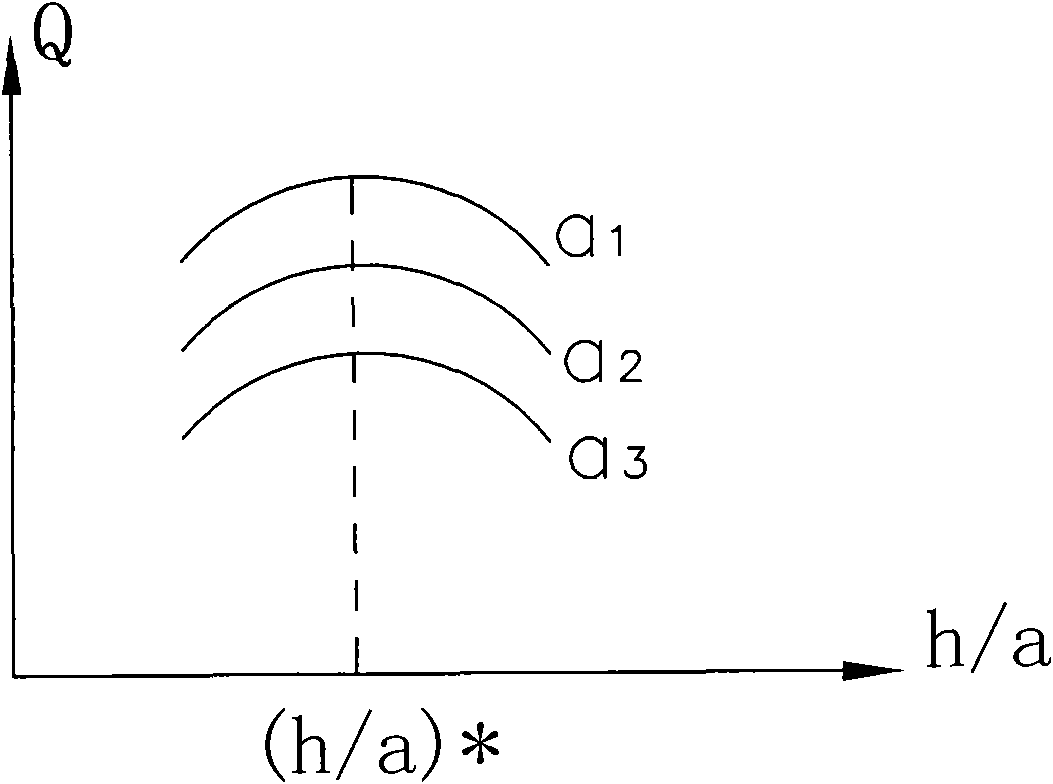

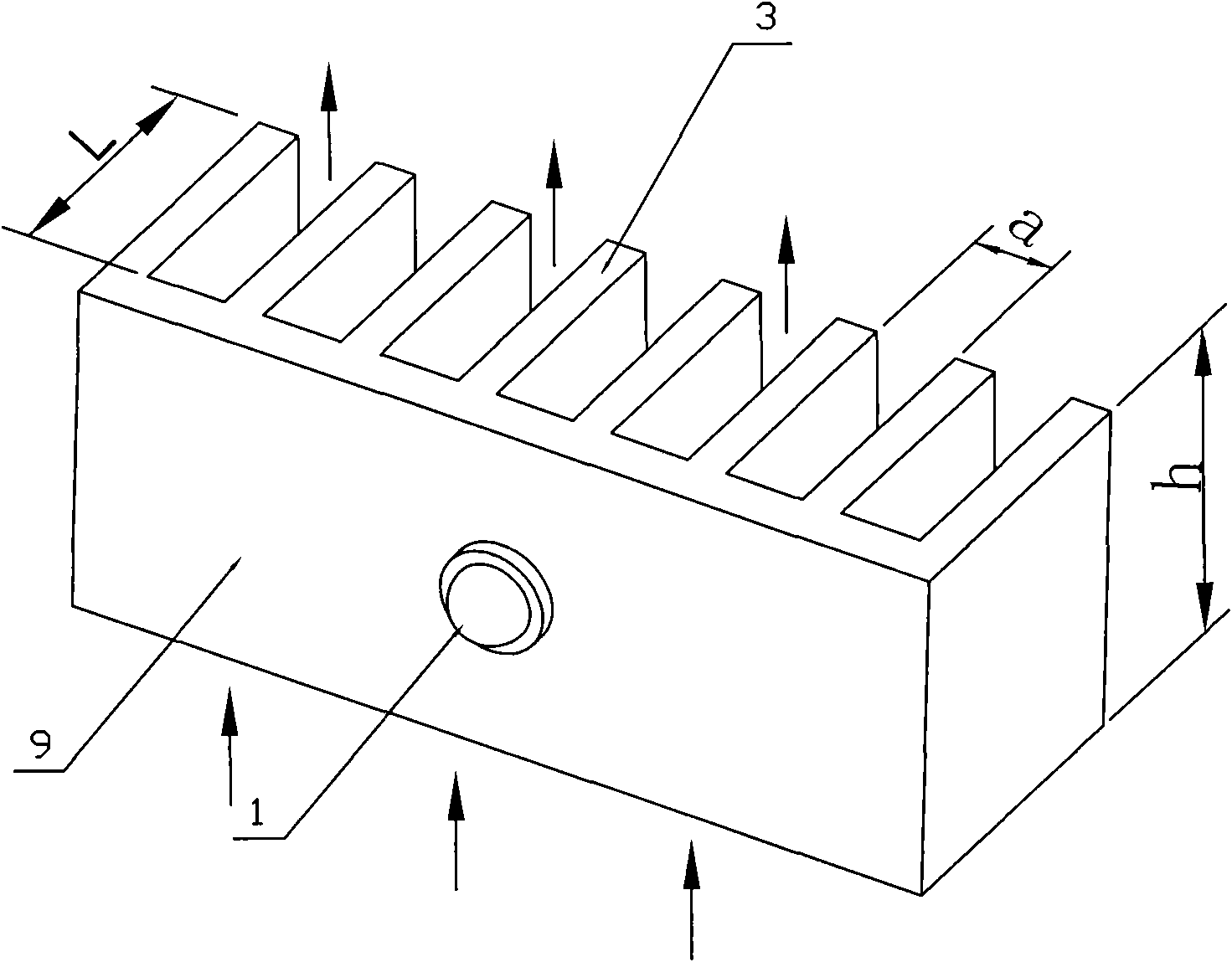

[0031] figure 2 In the LED lamp shown, the LED core 1 is arranged on the side of the heat-conducting block 9, the fin 3 extends from the other side of the heat-conducting block 9, and the length L of the protrusion is the length of the fin. In the figure, the heat conduction block 9 is erected, and the fins 3 are also erected. The arrows in the figure indicate air flow. In natural convection, the air passes through the fins 3 from bottom to top. The height h of the fins is the direction in which the air passes through the fins. The gap a between the fins is the space distance between two adjacent fins.

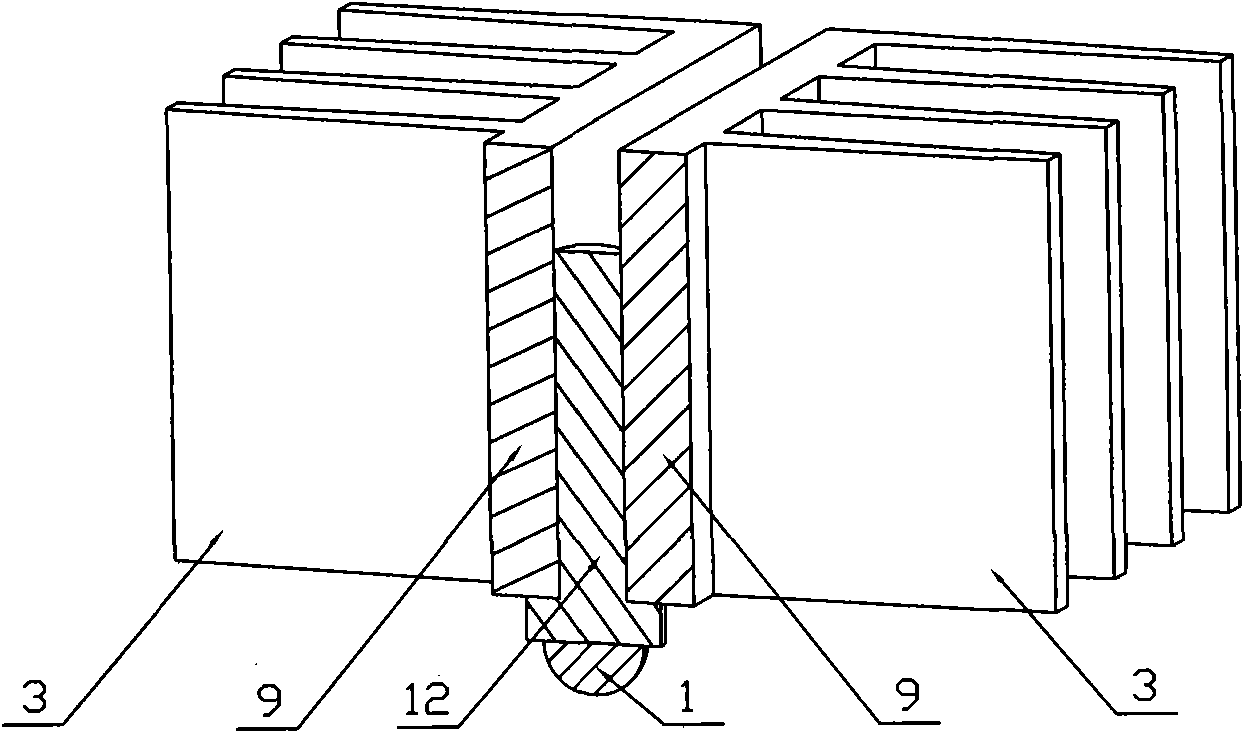

[0032] image 3 In the LED lamp shown, the LED core 1 is arranged on the lower end surface of the thermally conductive block 9 with two heat sinks. The thermally conductive core 12 of the LED core 1 is sandwiched by the thermally conductive blocks 9 of the two heat sinks, and the heat of the LED wick 1 passes through the thermally conductive core 12 Transfer to the heat conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average clearance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com