Gap sensor calibration system of magnetic-levitation train

A technology of gap sensors and maglev trains, which is applied in the directions of instruments, electromagnetic means, measuring devices, etc., can solve the problems such as the inability to meet the horizontal movement speed requirements of the gap sensors, the inability to calibrate the gap sensors to measure the speed, and the large workload of calibration and maintenance. , to achieve the effect of compact structure, low cost, overcoming wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

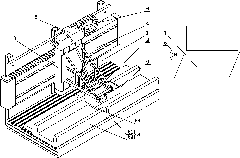

[0017] Such as figure 1 and figure 2 As shown, the maglev train gap sensor calibration system in this embodiment includes a base 1, a sensor fixture 2 for installing the gap sensor 9 to be calibrated, a vertical drive unit 3, a control mechanism and a track 8 located on the base 1, and the sensor The fixture 2 is fixed on the vertical drive unit 3, the track 8 is arranged directly below the sensor fixture 2, the base 1 is provided with a horizontal drive unit 4, the vertical drive unit 3 is fixed on the horizontal drive unit 4 and can be driven by the horizontal drive unit 4 The drive moves along the horizontal direction, and more than one joint 83 is provided on the track 8, and the control mechanism is respectively connected with the vertical drive unit 3, the horizontal drive unit 4 and the gap sensor 9 to be calibrated.

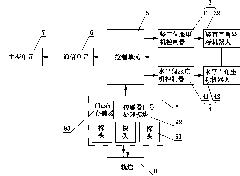

[0018] In this embodiment, the control mechanism includes a control unit 5, a communication unit 6 and a main control unit 7, the control unit 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com