Sizing mixture water-supplementing device for producing battery pole piece

A technology of mixing slurry and battery pole pieces, applied in the direction of electrode manufacturing, etc., can solve the problems of poor operation stability, thickening of slurry, and affecting the qualification rate of pole pieces, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

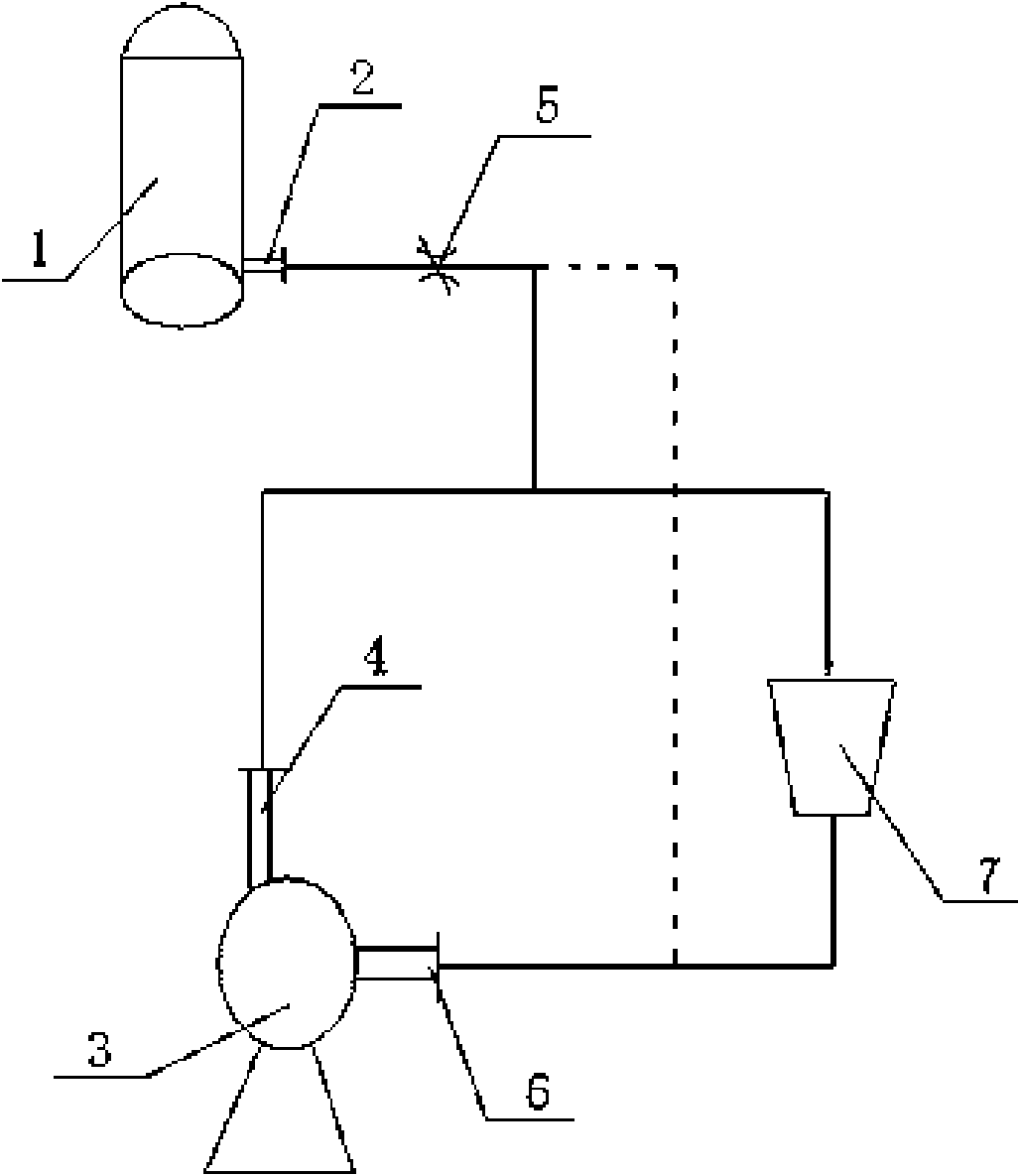

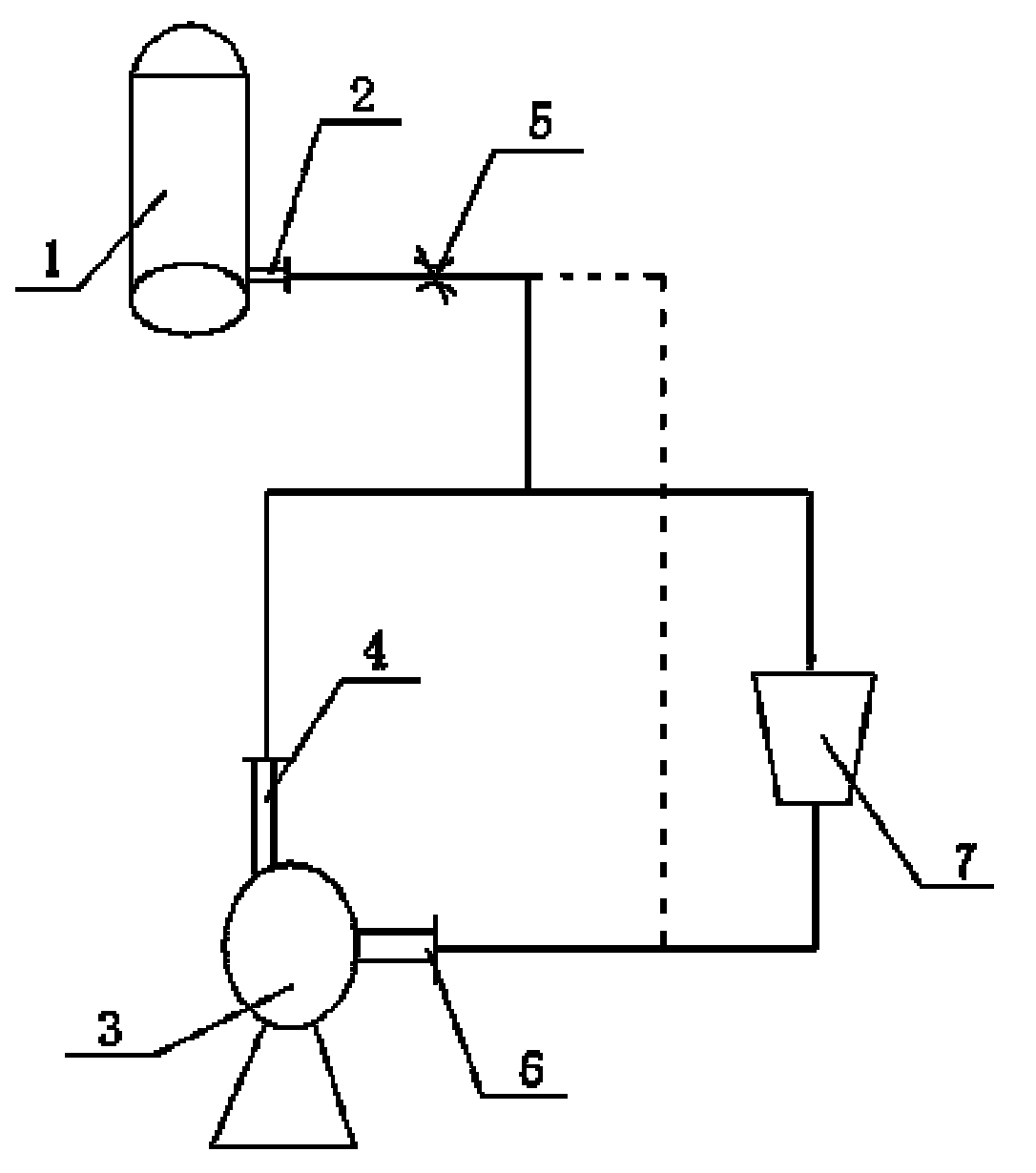

[0011] refer to figure 1 , this embodiment includes a high-level water storage tank 1 and a circulation pump 3, the outlet 2 of the high-level water storage tank 1 communicates with the inlet 4 of the circulation pump 3, and a joint is installed on the connecting pipe between the high-level water storage tank 1 and the circulation pump 3 The flow valve 5; the outlet 6 of the circulating pump 3 communicates with the feed port at the lower end of the slurry hopper 7, and the inlet 4 of the circulating pump 3 communicates with the discharge port at the upper end of the slurry hopper 7; each connecting pipe adopts a hose.

[0012] When working, open the throttle valve 5, the supplementary water in the high-level water storage tank 1 flows into the inlet pipe of the circulation pump 3 by itself, the supplementary water is mixed with the slurry in the pipeline, and then pumped into the slurry hopper 7 with the circulation pump 5, through which This way maintains the fluidity and wat...

Embodiment 2

[0015] The difference between this embodiment and embodiment 1 is that the outlet 2 of the elevated water storage tank 1 communicates with the outlet 6 of the circulating pump 3 (refer to figure 1 The connection mode shown by the dotted line in the middle), the remainder is the same as in embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap