Multi-stage pump rotor for turbo-molecular pump

A technology of turbomolecular pump and multi-stage pump, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as the weakening of the inherent design of the rotor, and reduce the risk of bursting and damage. force and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

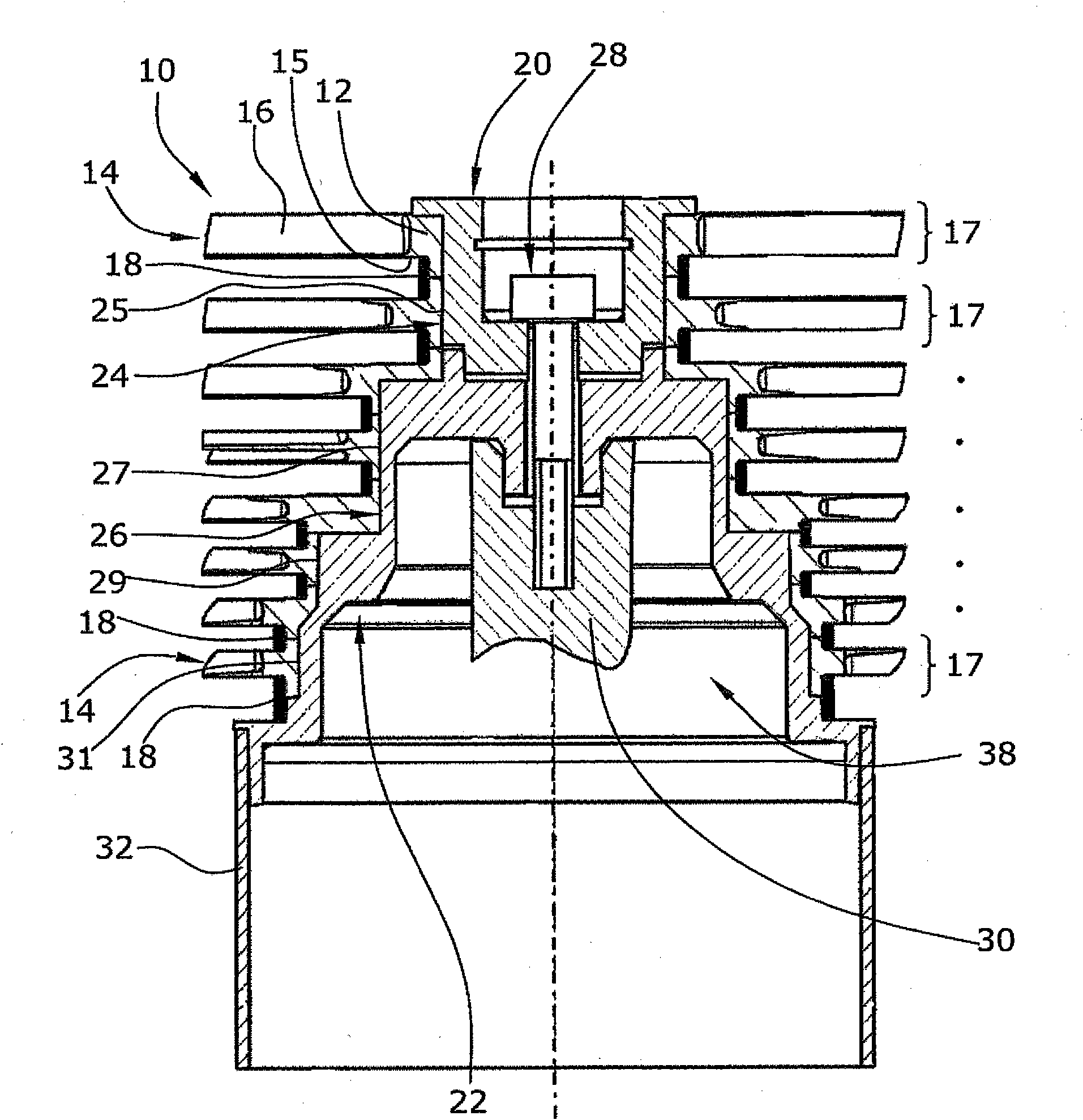

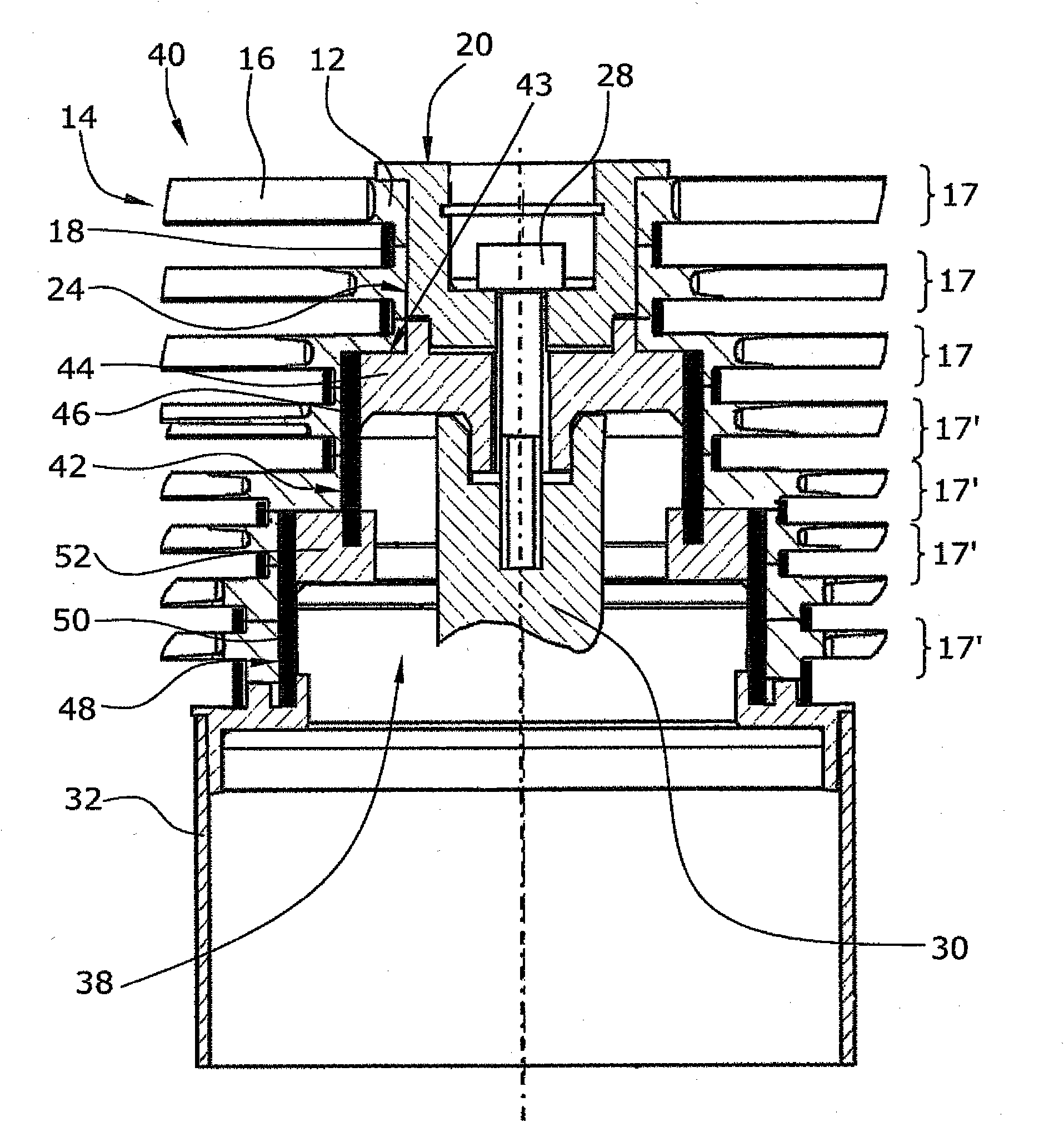

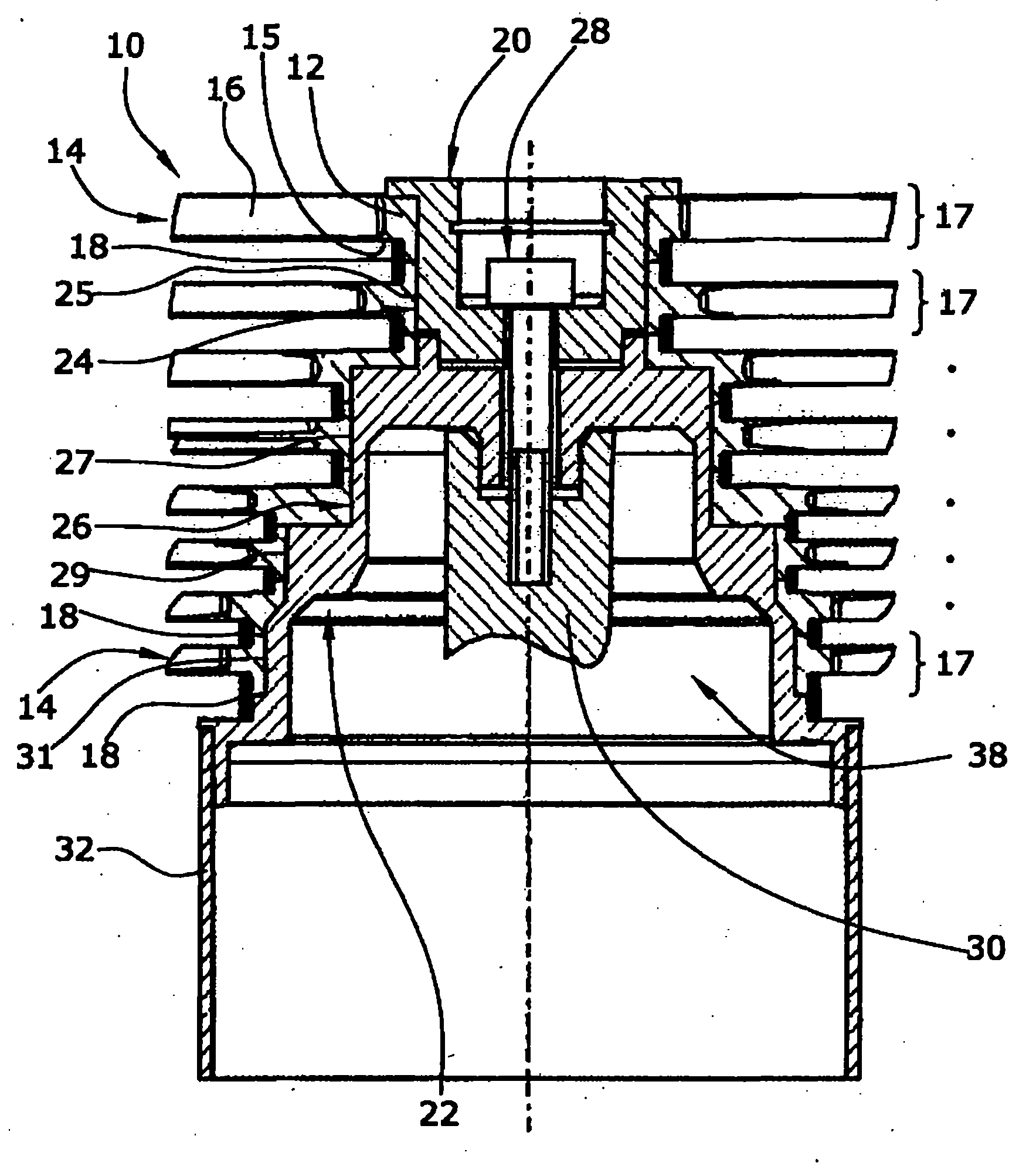

[0024] exist figure 1 and 2 In , multistage pump rotors 10, 40 for turbomolecular pumps are shown, respectively. The pump rotor 10, 40 is adapted to rotate at a nominal rotational speed of 20,000 r / min to 100,000 r / min. The two pump rotors 10 , 40 have approximately the same design, only their internal construction differs from one another.

[0025] according to figure 1 The rotor 10 is substantially formed by eight blade disk rings 17 which are axially clamped to each other by means of two clamping bodies 20 , 22 which themselves are clamped by clamping screws 28 and the shaft 30 are axially clamped to each other. Furthermore, a rotor-side Holweck cylinder 32 is provided next to the blade disk ring 17 .

[0026] The pump rotor 10 is not designed as a one-piece unit, as conventional pump rotors of the prior art are, but consists of a plurality of blade disk rings 17 . Each blade disk ring 17 is formed by a closed rotor ring 12 with rotor blades 16 extending in radially o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com