Anti-dryout condensing device for detecting metal corrosivity

A condensing device and corrosive technology, which is applied in the field of anti-burning dry condensing devices for metal corrosion detection, can solve the problems of increasing cost, wasting water, and labor, so as to reduce the risk of bursting, improve cooling efficiency, and improve Effect of Cooling Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

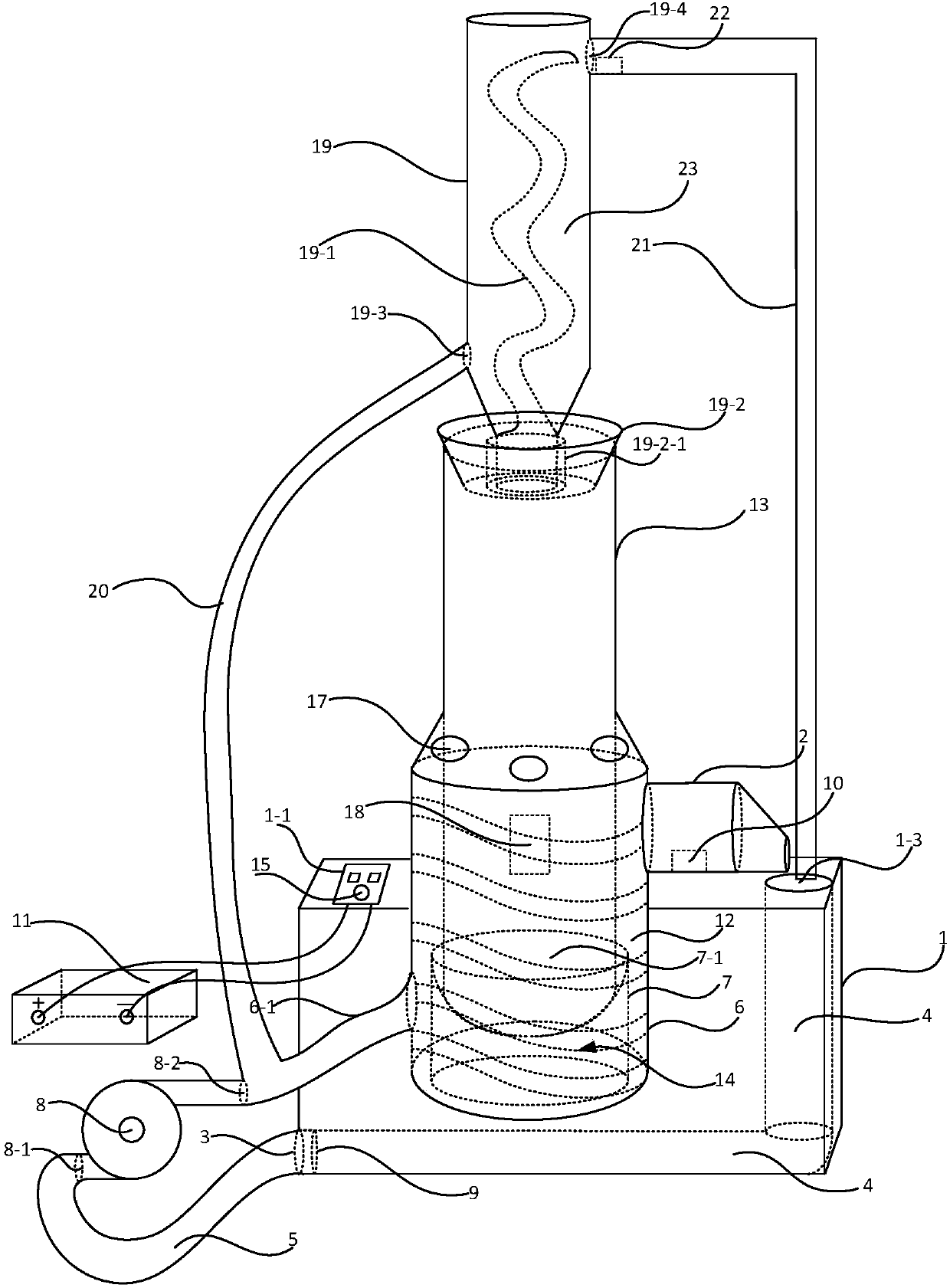

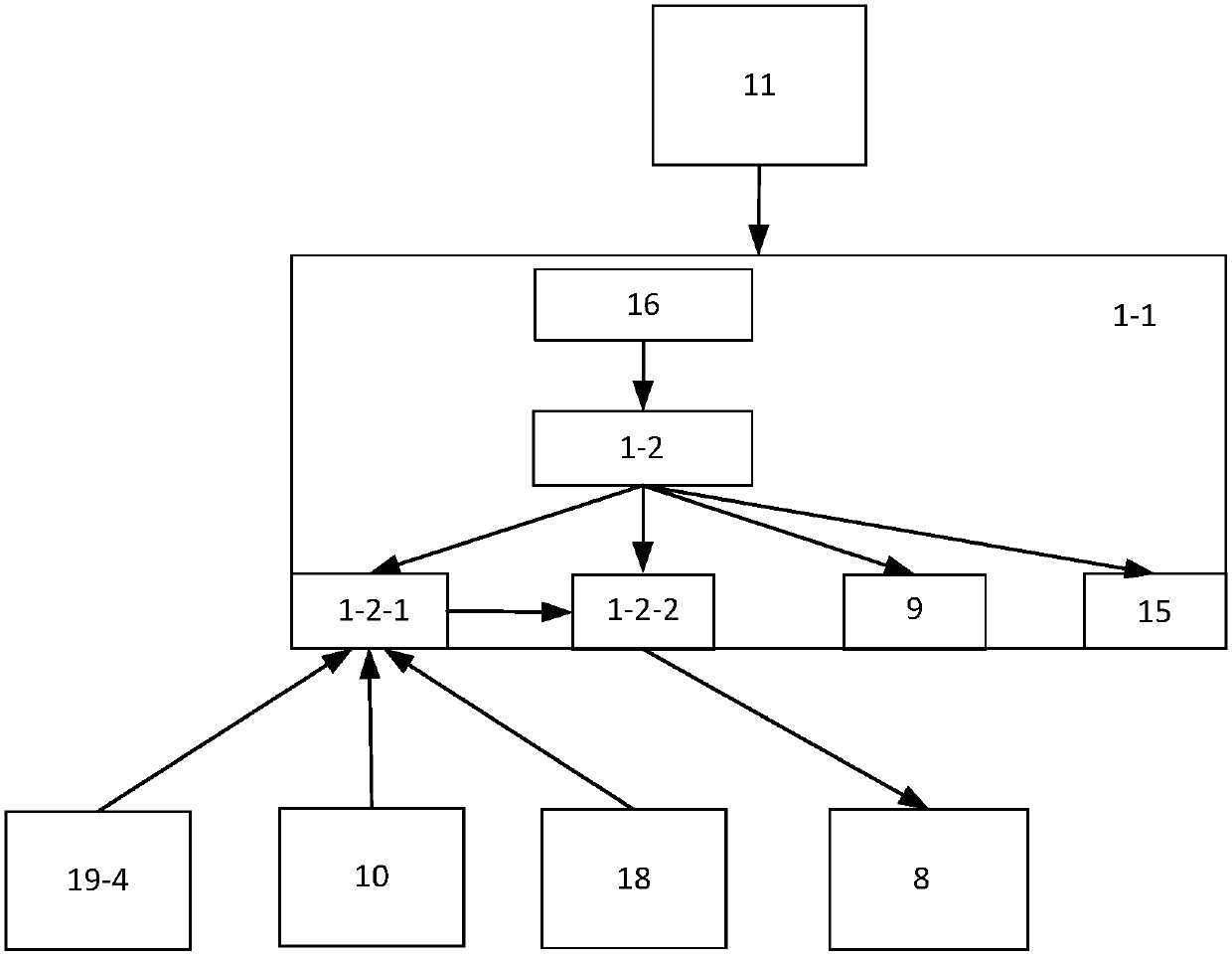

[0042] Embodiment: a kind of anti-burning dry condensation device for metal corrosion detection, such as figure 1 and figure 2 As shown, it includes a cooling box 1, the upper end surface of the cooling box is provided with a control panel 1-1, the inside of the control panel is provided with a single-chip control unit 1-2, and the center of the upper end surface of the cooling box has a jack , the lower end of the condenser 6 is inserted into the jack, and the upper end surface of the cooling box is also provided with a water receiving hole 1-3, and the water receiving hole is located directly below the drainage pipe 2, and the side of the lower end of the cooling box The wall is provided with a water outlet hole 3, and the inside of the cooling box is provided with a guide tube 4, one end of the guide tube is connected to the water receiving hole, and the other end of the guide tube is connected to the water outlet hole, the The water outlet hole is sealed and connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com