Deep scarification fertilizing method and device

A deep loosening and fertilizing machine technology, applied in fertilizing devices, fertilizer distributors, shovels, etc., can solve problems such as affecting effective fertilization, and achieve the effects of solving soil compaction and deterioration, high fertilization efficiency, and great social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of subsoiling fertilization method comprises the following steps:

[0030] Step 1. Crush the fertilizer until fine and fill it in the fertilizer box;

[0031] Step 2, start the oil pump of the power locomotive, the speed is 2200-2800 rpm, drive the hydraulic motor to rotate, the hydraulic motor speed is 86 rpm, start the blade auger of the mixing equipment, the blade auger speed is 36 rpm, Stir the fertilizer in the fertilizer tank;

[0032] Step 3. Start the plow mechanism and make grooves in the soil. The depth of the plow is 320mm;

[0033] Step 4, start the rotation of the blade auger of the fertilization mechanism, and transport the fertilizer to the fertilization pipe;

[0034] Step 5. Pull the flat plate after the fertilization pipe to fill the groove with soil;

[0035] Step 6. The spike-toothed harrow of the rolling mechanism rolls to compact the fertilized soil.

Embodiment 2

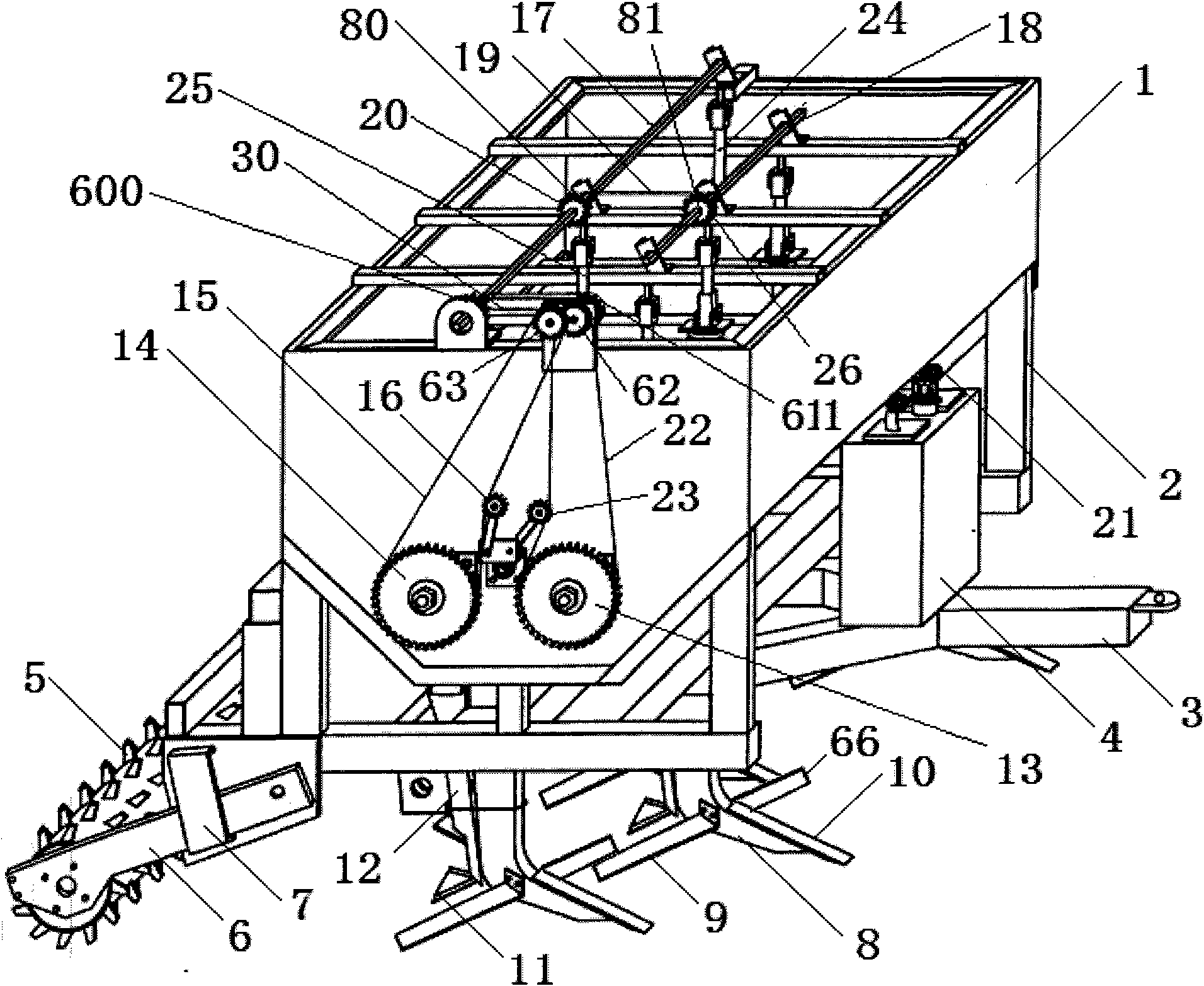

[0037] A subsoiling fertilizer applicator, including a frame, a fertilizer box, a hydraulic power mechanism, a stirring and fertilizing mechanism, a hydraulic lifting mechanism, a walking ground wheel device, a plow mechanism, and a rolling mechanism;

[0038] The frame is composed of welded section steel. There are support frames connected to the walking ground wheel device on the left and right sides of the bottom of the frame. The frame is fixedly connected to the fertilizer box. The front end of the frame is fixedly connected to the traction frame, and the rear end of the frame is fixedly connected to the rolling mechanism. ;The bottom of the frame is fixedly connected with the plowshare mechanism;

[0039] The rolling mechanism has a nail-toothed rake, a support frame, and a connecting frame. The nail-toothed harrow is cylindrical, and the surface of the nail-toothed harrow cylinder is covered with nail-toothed harrows. The rake shaft is respectively connected to the conn...

Embodiment 3

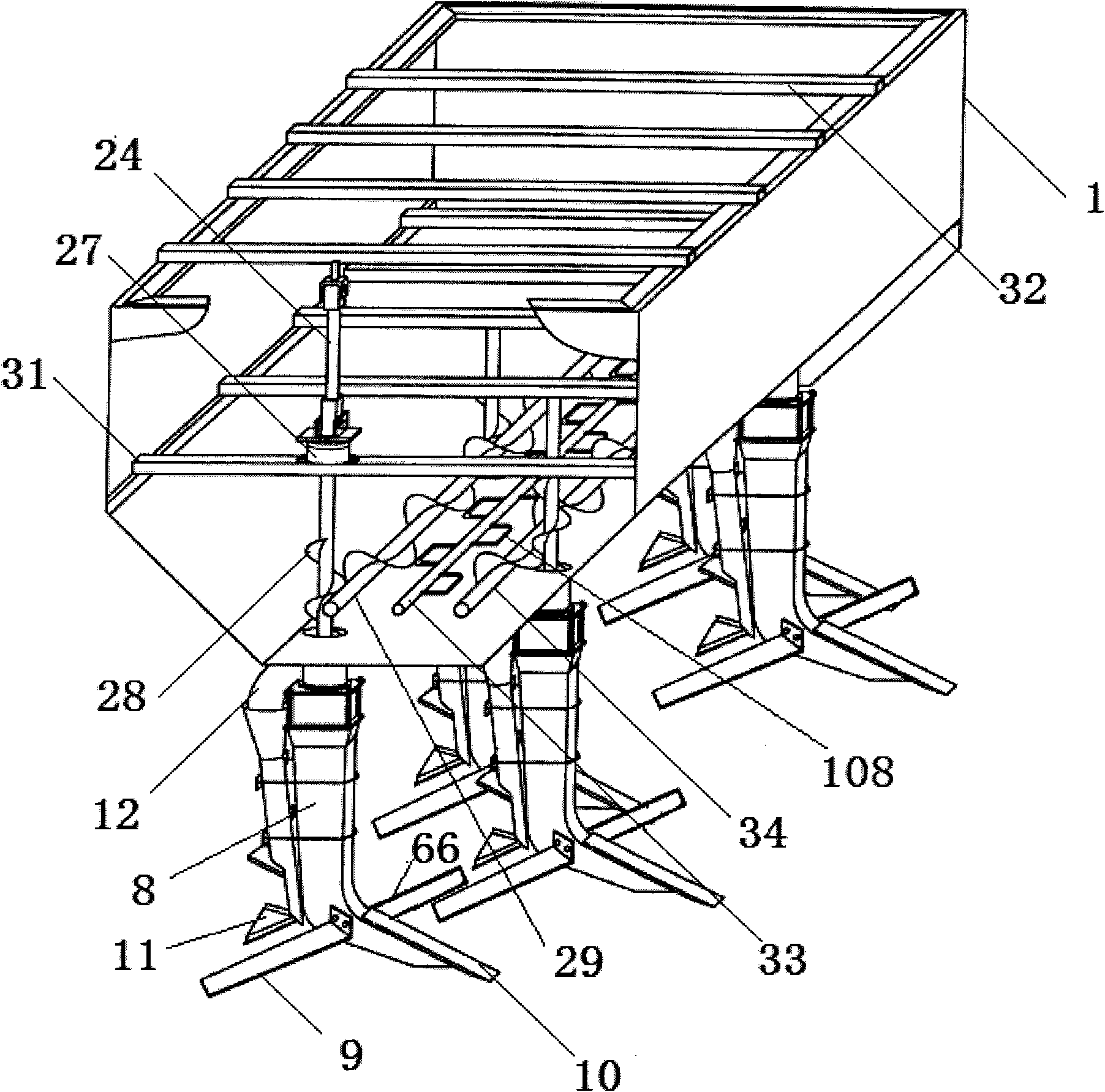

[0050] A subsoiling fertilizer applicator, comprising a frame 2, a fertilizer box 1, a power mechanism, a stirring and fertilizing mechanism, a hydraulic lifting mechanism, a walking ground wheel device, a plow mechanism, and a rolling mechanism;

[0051] The frame 2 is made up of welded section steel. There are support frames connected to the walking ground wheel device on the left and right sides of the bottom of the frame 2. The frame 2 is fixedly connected to the fertilizer box 1. The front end of the frame 2 is fixedly connected to the traction frame 3. The rear end is fixedly connected with the rolling mechanism; the bottom of the frame 2 is fixedly connected with the plow mechanism, and the traction frame 3 is connected with the tractor (tractor or automobile);

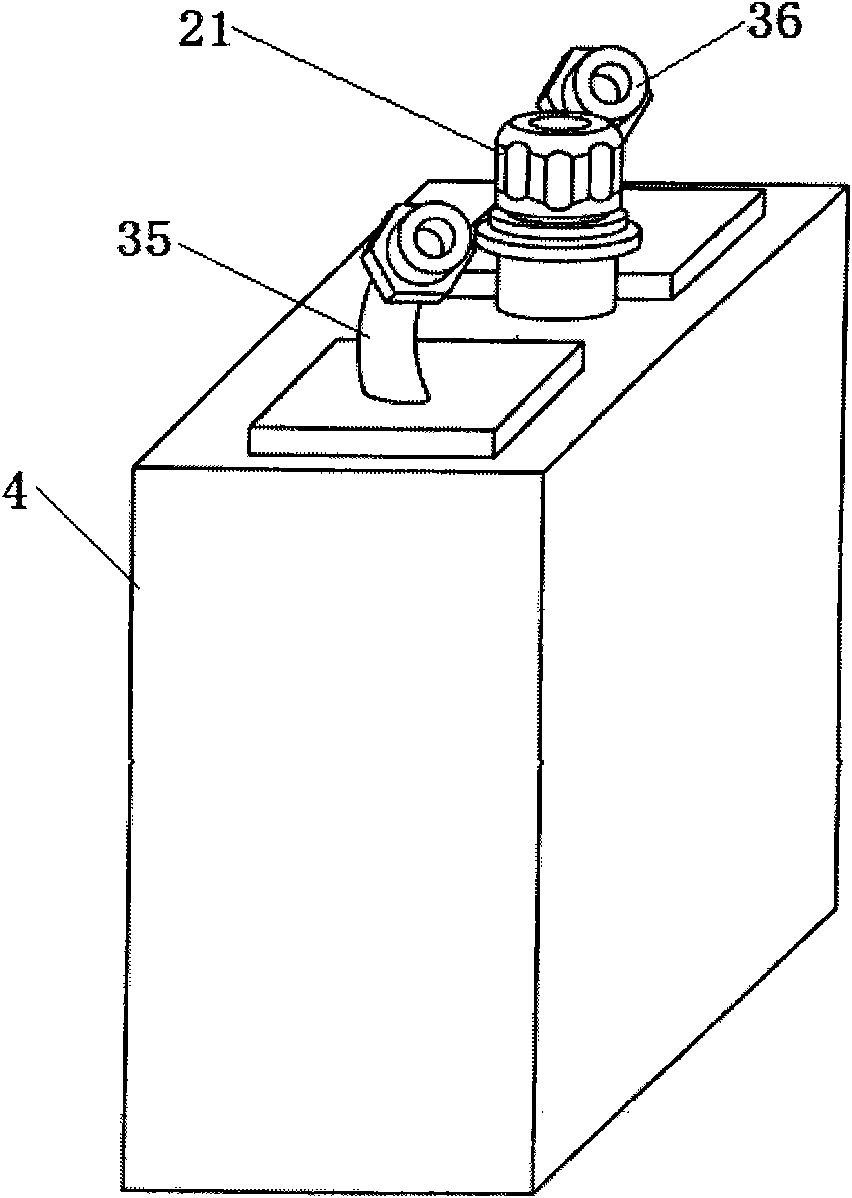

[0052] The top of fertilizer box 1 is fixed with cross bar 32, and the middle part is fixed with support cross bar 31, and cross bar 32 and support cross bar 31 have many, and support cross bar 31 fixes bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com