Winding preventing fruit picking roller mechanism

A fruit picking roller and anti-winding technology, which is applied to harvesters, digging harvesters, agricultural machinery and tools, etc., can solve the problems of many broken seedlings and branches, high rate of fruit pods with stalks, and difficult cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

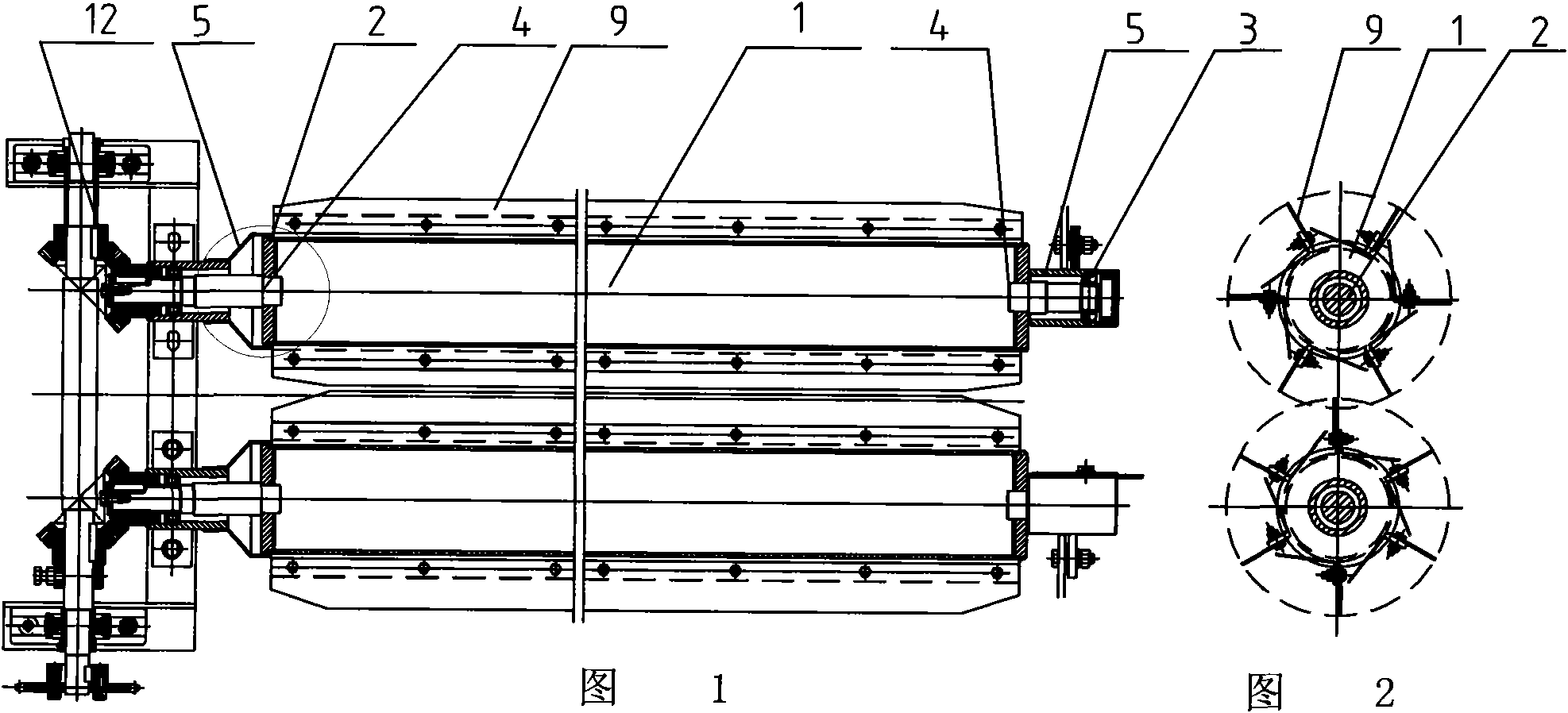

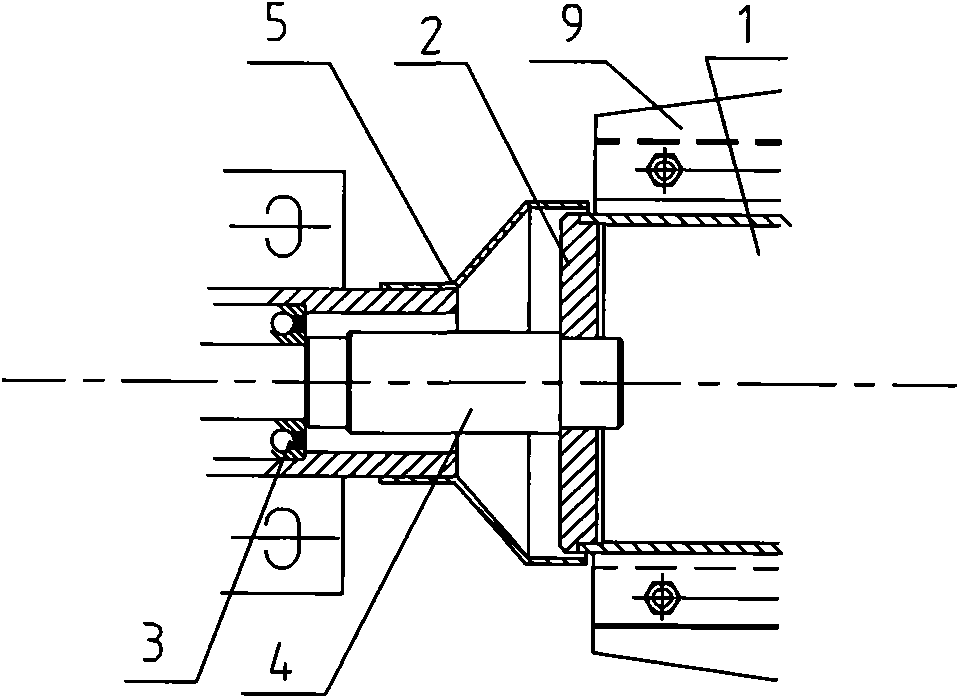

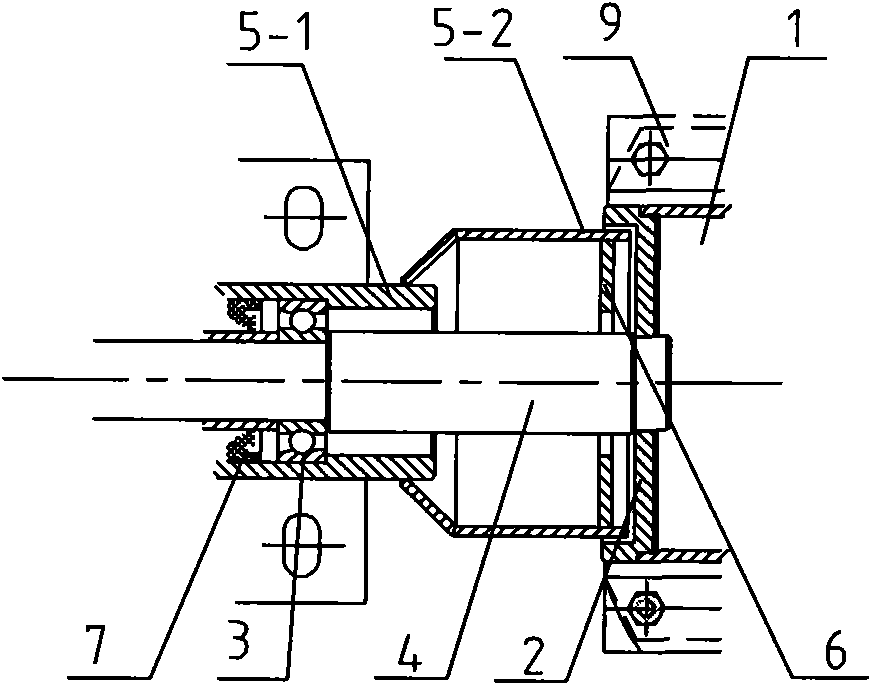

[0019] The anti-winding fruit picking roller mechanism of the present embodiment is as follows: Figure 4 , 5 As shown in , 6, it contains a pair of relative rotatable roller bodies 1 that are assembled in different phases. A group of fruit-picking blades 9 that are evenly distributed in the radial direction are installed on the outer circular surface of the roller body 1, and the end plates 2 at both ends extend out respectively. The rotating shaft 4 supported on the frame by the bearing 3 is fixed on the frame with a tubular shield 5 extending from the outer ring of the bearing 3 to the end plate 2 of the roller body, and the end surface of the end plate 2 adjacent to the shield 5 is formed with a circular depression The outer diameter of the shield 5 adjacent to the end plate 2 and the inner diameter of the circular depression form a moving fit gap, and extend into the circular depression.

[0020] Since one end of the roller body is a power input end and the other end has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com