Rotating disc knife, method of mounting the rotating disc knife and method of dismounting the rotating disc knife

A technology of rotating discs and disc knives, which is applied to the knives of sawing machine devices, metal sawing equipment, food science, etc., and can solve problems such as knife damage and cigarette lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

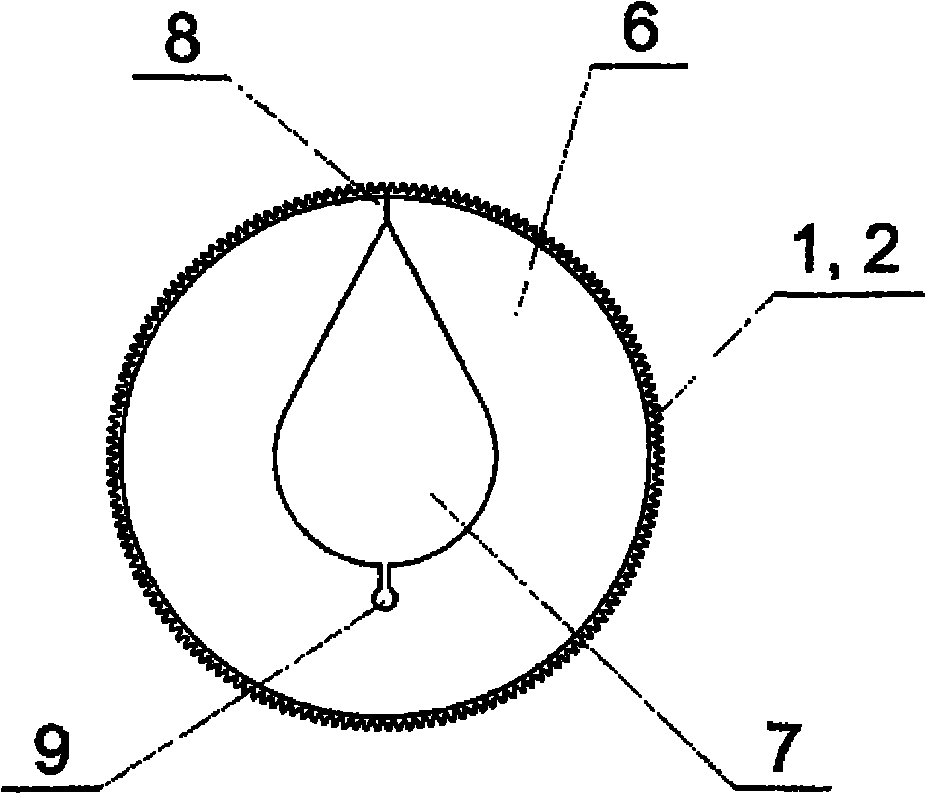

[0042] figure 1 A projection of the knife according to the invention on a plane parallel to its disc 6 is shown. The teeth 1 , 2 are located on the circumference of the disc 6 . The disk cutter has an opening 7; in this case the opening 7 is drop-shaped, but the shape of the opening can also be different. The opening 7 joins the cutting edge 5 of the knife at said edge discontinuity 8 . Opposite the location 8 a further cutout 9 can be formed.

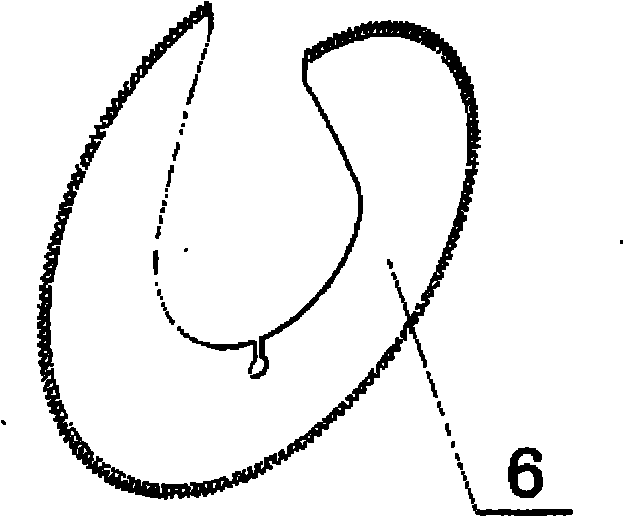

[0043] figure 2 A perspective view showing a knife according to the invention after the free end of the cutting edge 5 has been pulled apart to mount the knife to or remove the knife from the shaft of the cutting assembly tear down.

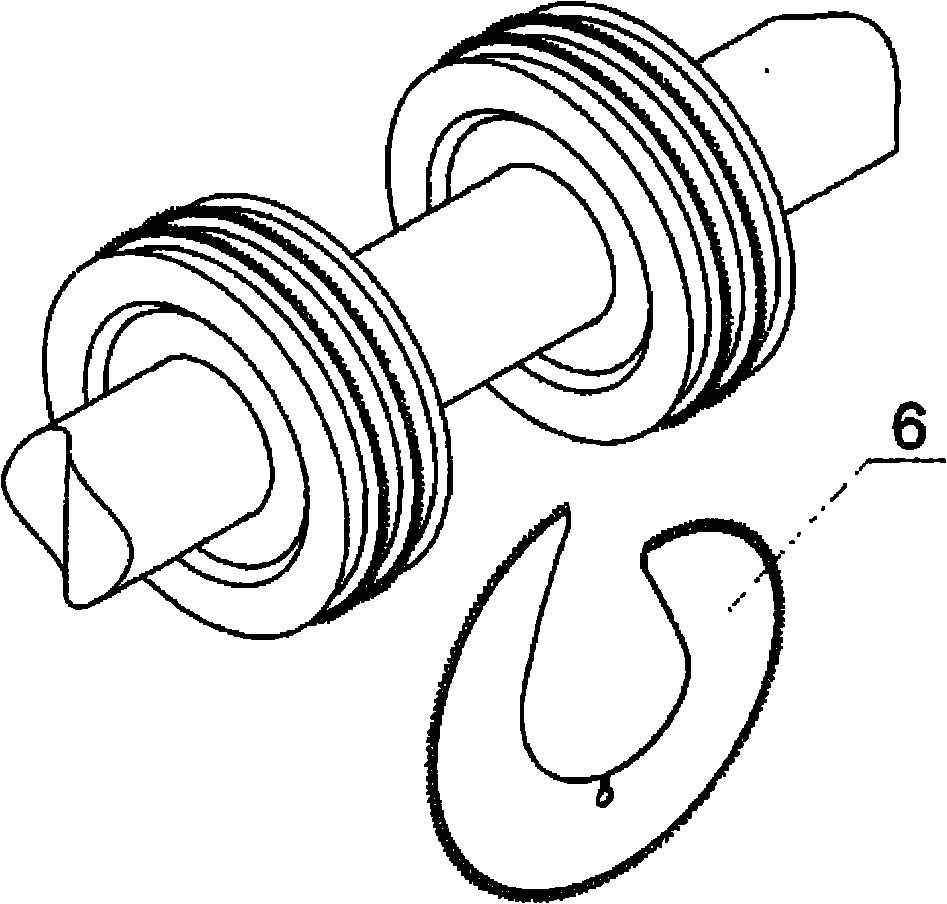

[0044] Figure 3 to Figure 5 The successive stages of changing the knife are shown. In this way, a damaged knife can be replaced by following these steps:

[0045] Loosen the mechanism that attaches the knife to the shaft;

[0046] Slide the knives apart so that there is free space near the dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com