Filter device for a textile machine for the production of cross-wound spools

A technology of cross-winding bobbins and filter devices, which is applied in textile and papermaking, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of complex manufacturing, achieve the effect of small wind loss and optimized air passage holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

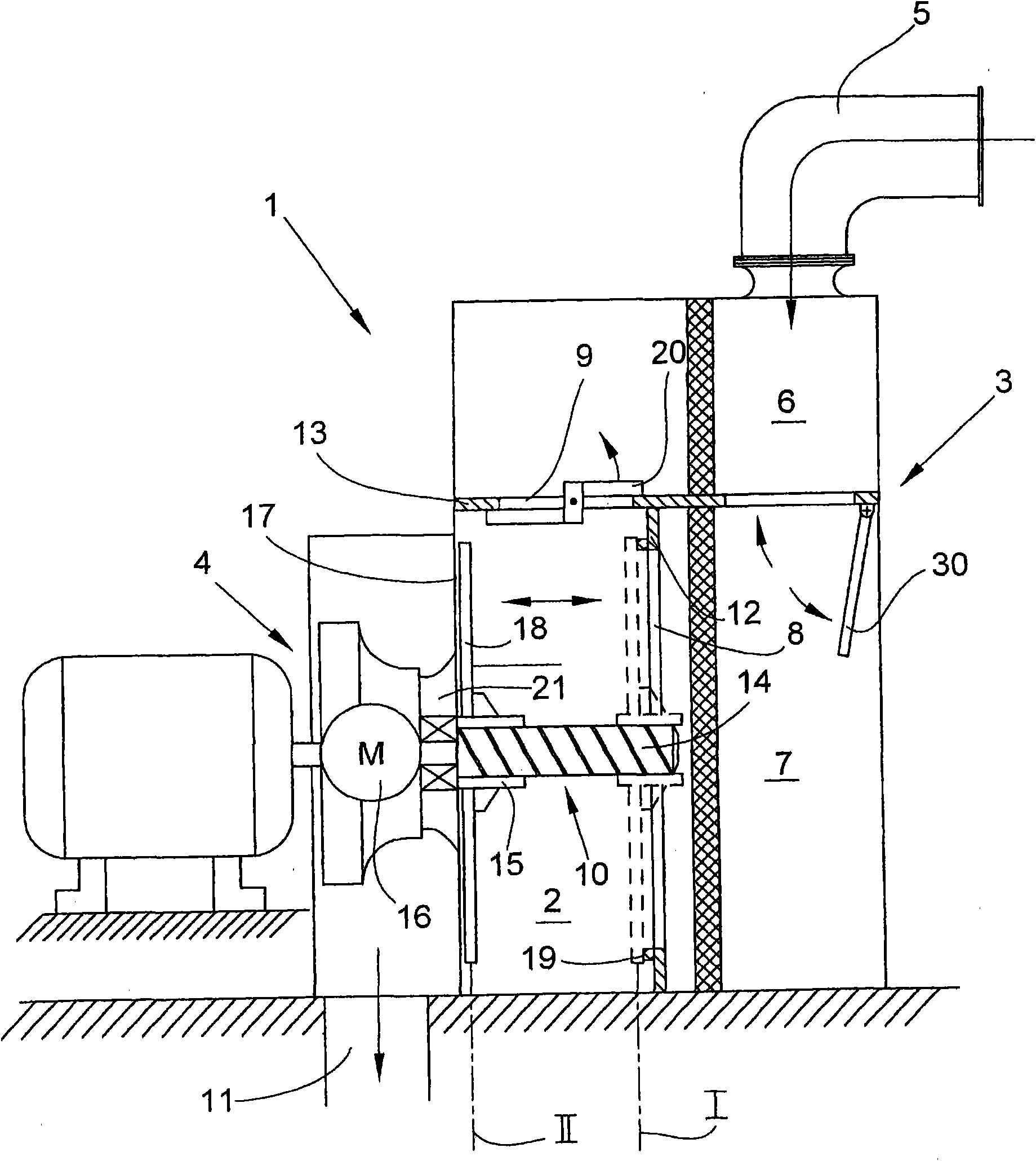

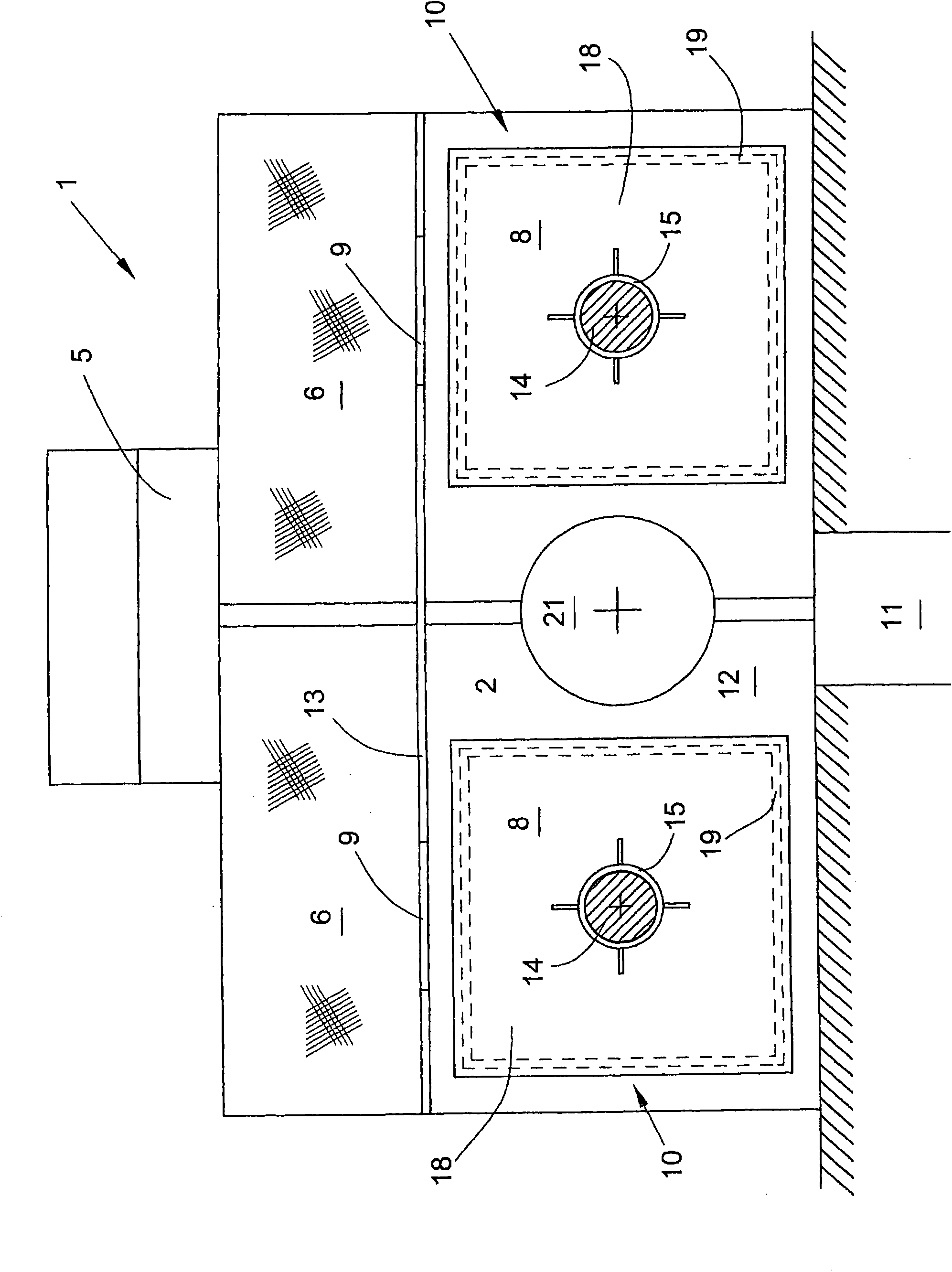

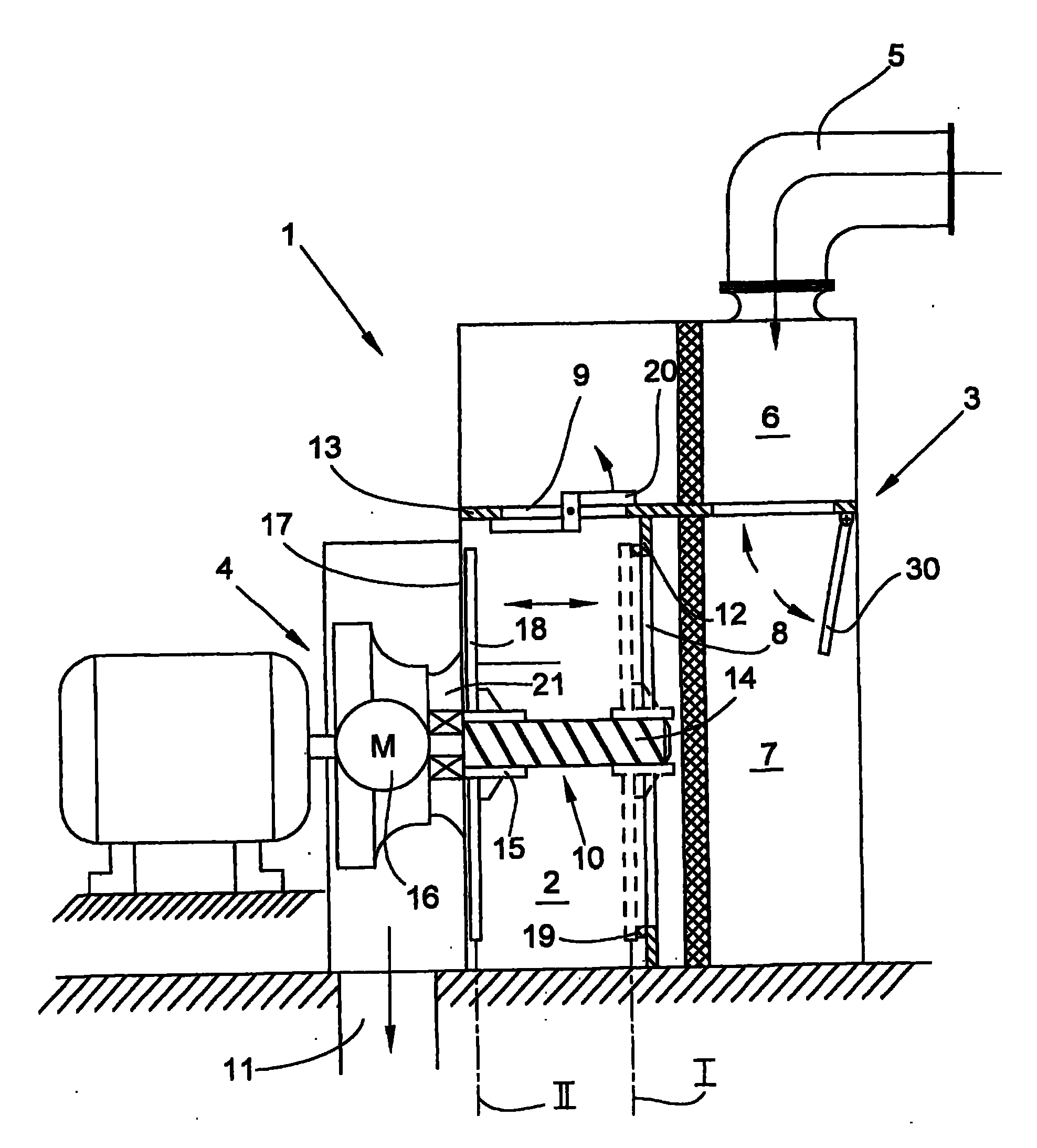

[0021] figure 1 A filter device of a textile machine for producing cross-wound bobbins shown in side view as an example in FIG. The filter device 1 is connected via a suction channel 5 shown schematically to a wind consumer (not shown) of the textile machine and via an exhaust channel 11 to a spinning mill-specific suction device. In the illustrated embodiment, the filter device 1 has two adjacently arranged identical filter chambers 3 , both of which are connected to an intermediate chamber 2 which is connected laterally to a vacuum source 4 . The filter chamber 3 is here divided into a main filter chamber 7 and a spare filter chamber 6, wherein the main filter chamber 7 is connected to the intermediate chamber 2 through the air passage hole 8 arranged in the partition 12, and the spare filter chamber 6 is connected to the intermediate chamber 2 through the air passage hole 8 in the partition 12. The air passage hole 9 in 13 is connected with the intermediate chamber 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com