Grain cutting cover for extruder

An extruder and pelletizing technology, which is applied in the field of blown-type pelletizing hood, can solve the problems of difficulty in observing pelletizing and pelletizing at the head and die, reducing production efficiency, complicated operation, etc., and achieves reliable performance, Improve production efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

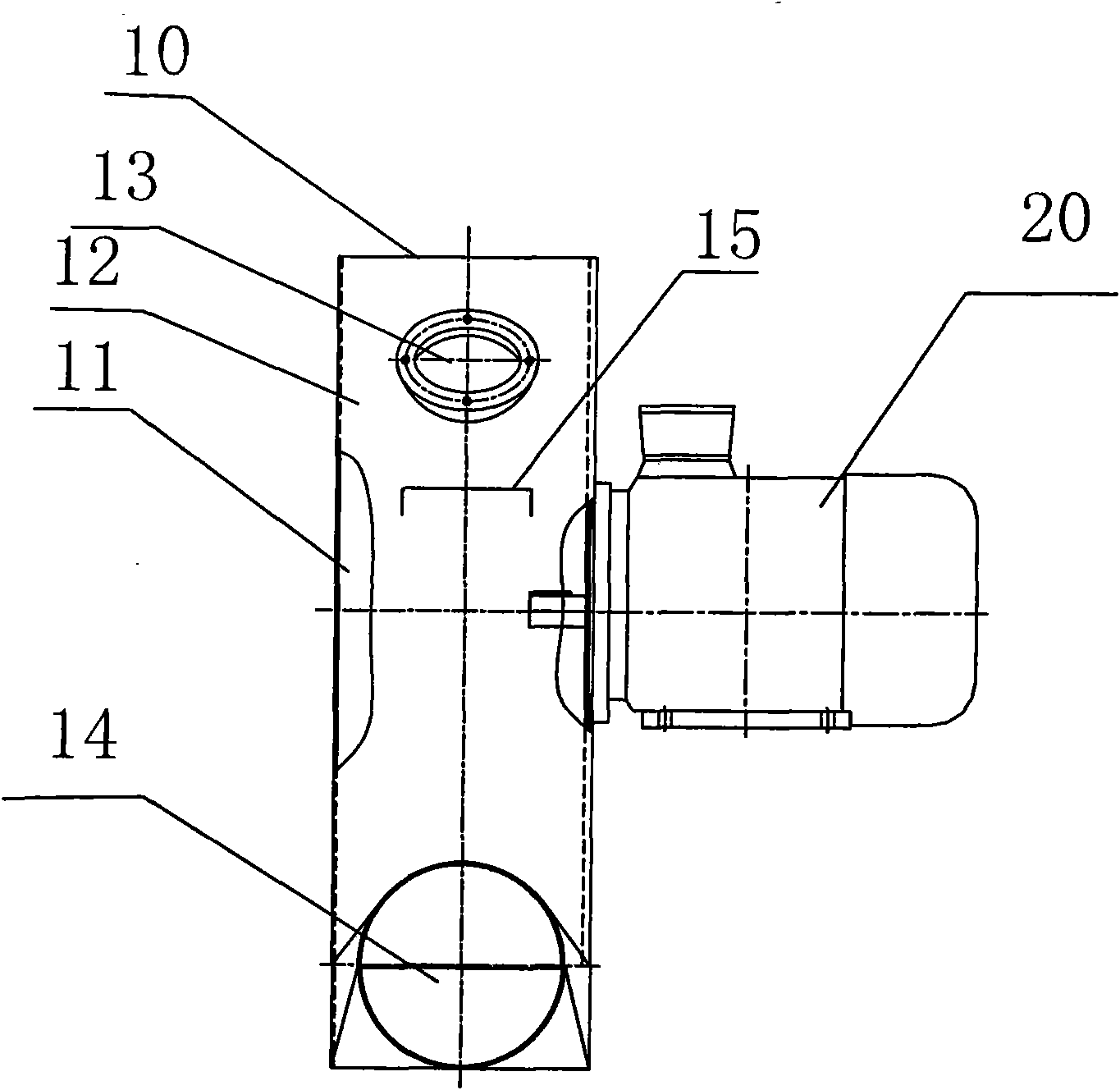

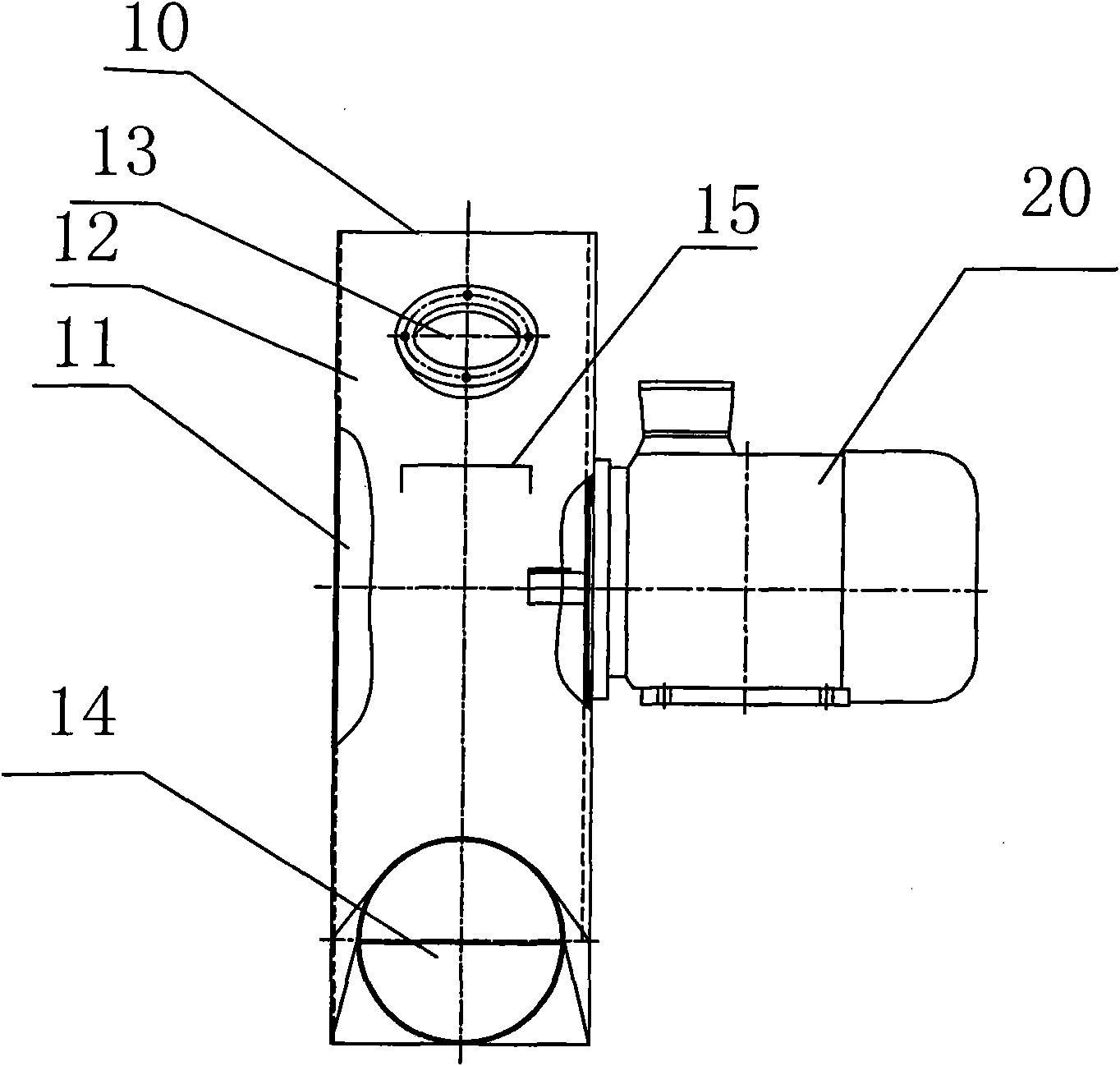

[0015] see figure 1 , the pelletizing hood for the extruder in this embodiment includes a circular hood 10; an air inlet duct and an air outlet duct 14 are arranged at the bottom of the circular hood 10, and the opening of the air inlet duct and the air outlet duct 14 is opposite , A blower fan can be installed at the mouth of the air inlet pipe to dry and blow the granulated materials. A circular hole 11 matching the head of the granulator is opened at the center of one side of the circular cover 10, and the pelletizing cover is set on the head through the circular hole 11, so that the outlet of the machine head The granulated part is completely placed in the granulating hood, and the cut granulated material can be sent to the air outlet channel by the wind force of the blower.

[0016] A motor 20 is fixedly installed at the circular place on the other side of the circular cover body 10, and the main shaft of the motor 20 passes through the circular cover body 10 and the pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com