Constant-speed control device of multiple-protection agitating lorry

A constant speed control, mixer truck technology, applied in concrete transportation and other directions, can solve the problems of aggravating the wear and tear of the spiral blade and the cylinder, solidification, and poor vehicle driving stability, so as to increase the driving stability, improve the transportation quality, and prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

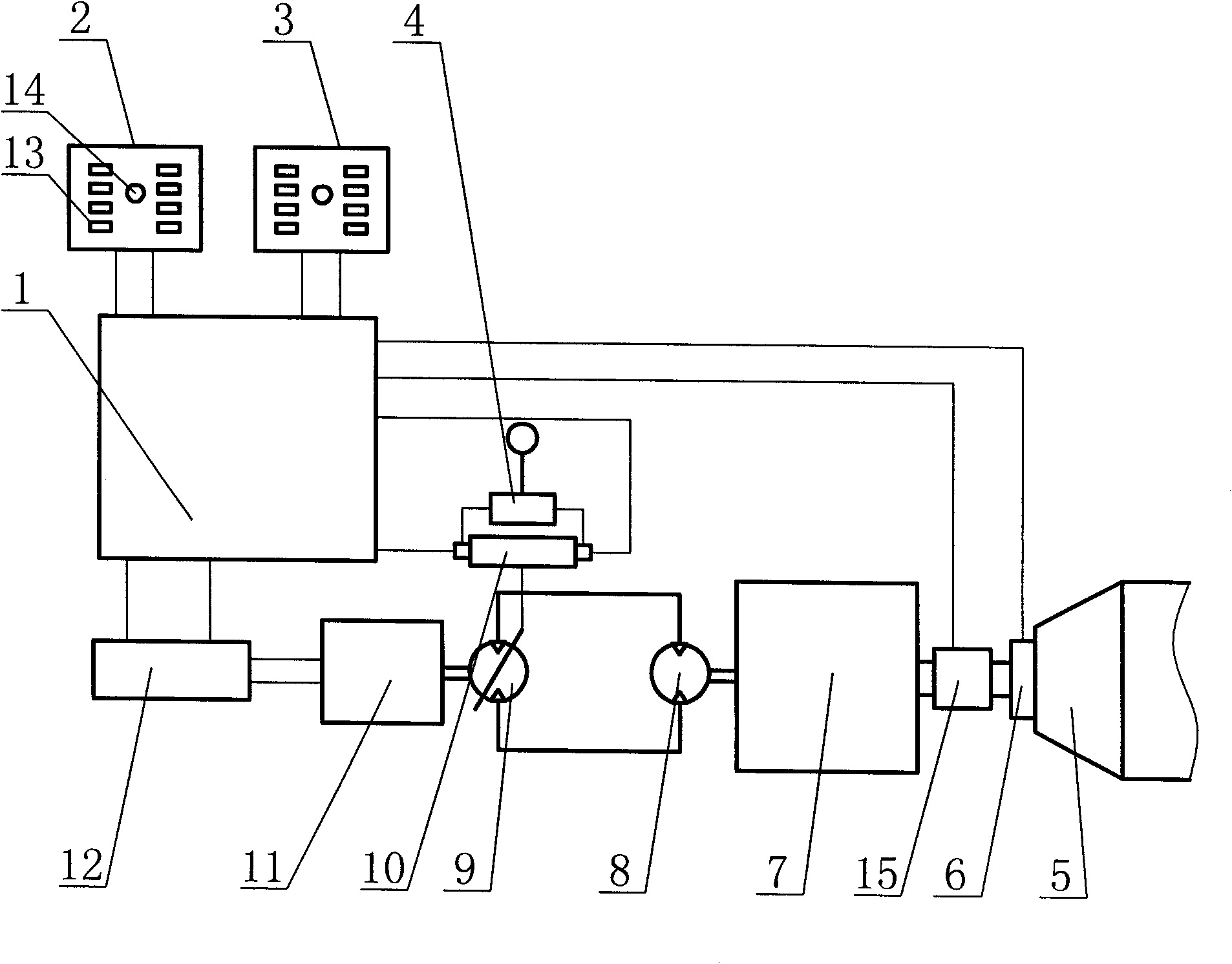

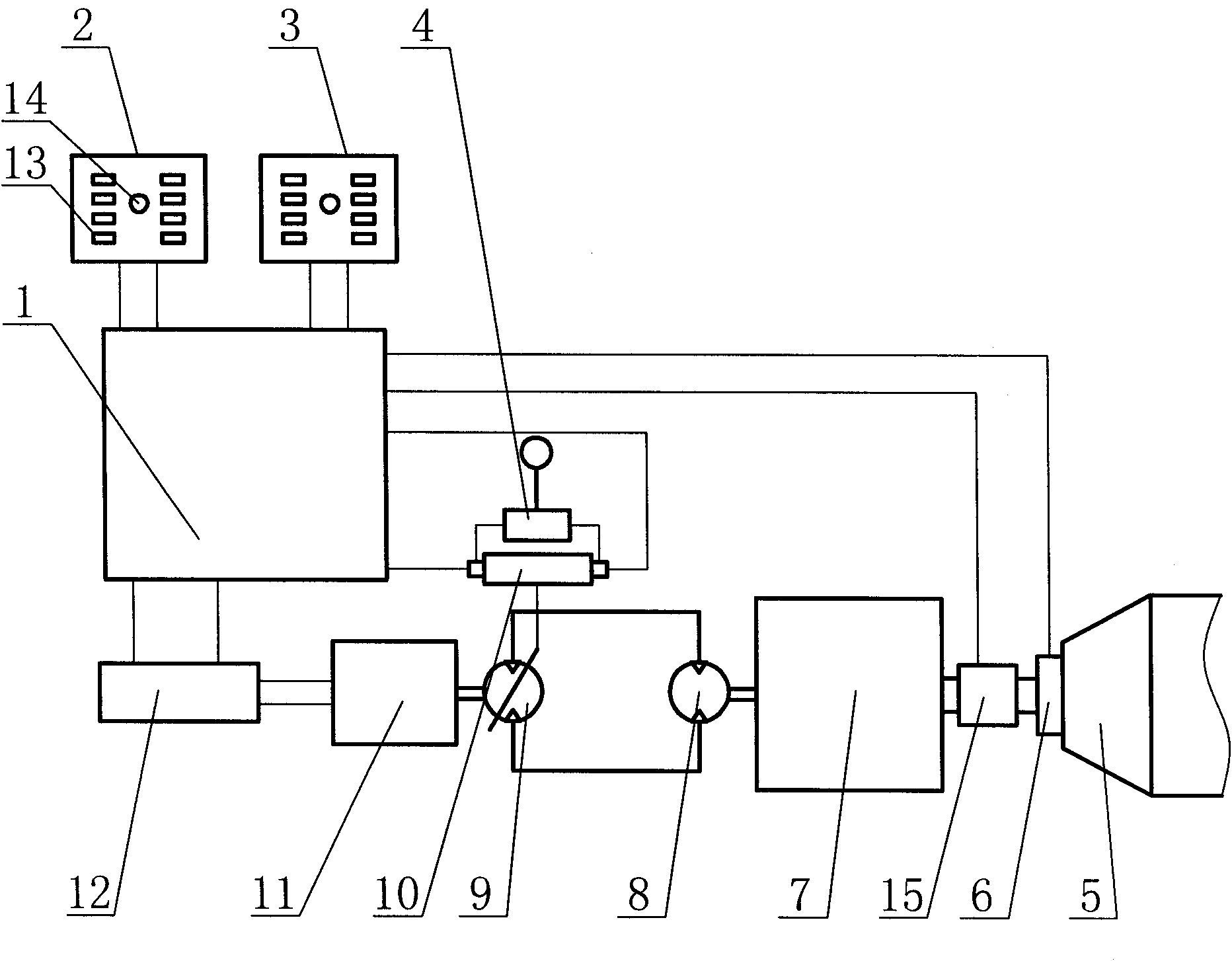

[0010] The present invention will be further described with reference to accompanying drawing:

[0011] The basic operating principle of the constant speed control device provided by the present invention is: by main manipulator 2 or The manipulator 3 sets a constant speed command for the controller 1, and the controller 1 adjusts the state of the electronically controlled proportional control valve 10 according to the constant speed requirement in combination with the engine 11 speed and the feedback speed of the hydraulic motor at this time, so that the hydraulic pump does not matter whether the engine 11 How to change the rotating speed, always maintain a constant displacement, and then stabilize the rotating speed of the mixing drum 5 .

[0012] Such as figure 1 As shown, a constant speed control device for a multi-protection mixer truck according to the present invention, the main structure includes a hydraulic pump and a hydraulic motor. The hydraulic pump is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com