Self-locking mechanism for upper pressure beam of broken tape protection device

A protection device and self-locking technology, which is applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as inconvenient use, inconvenient production, and affecting the normal operation of the conveyor, so as to improve work efficiency and reduce troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

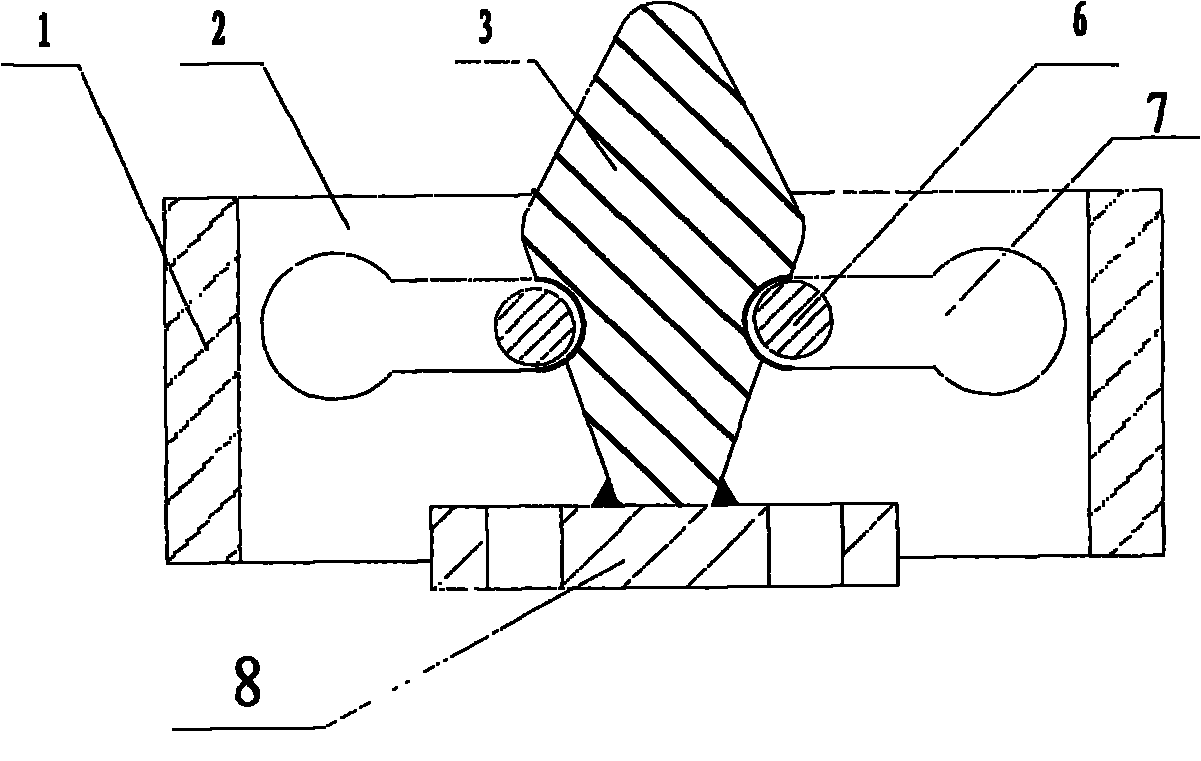

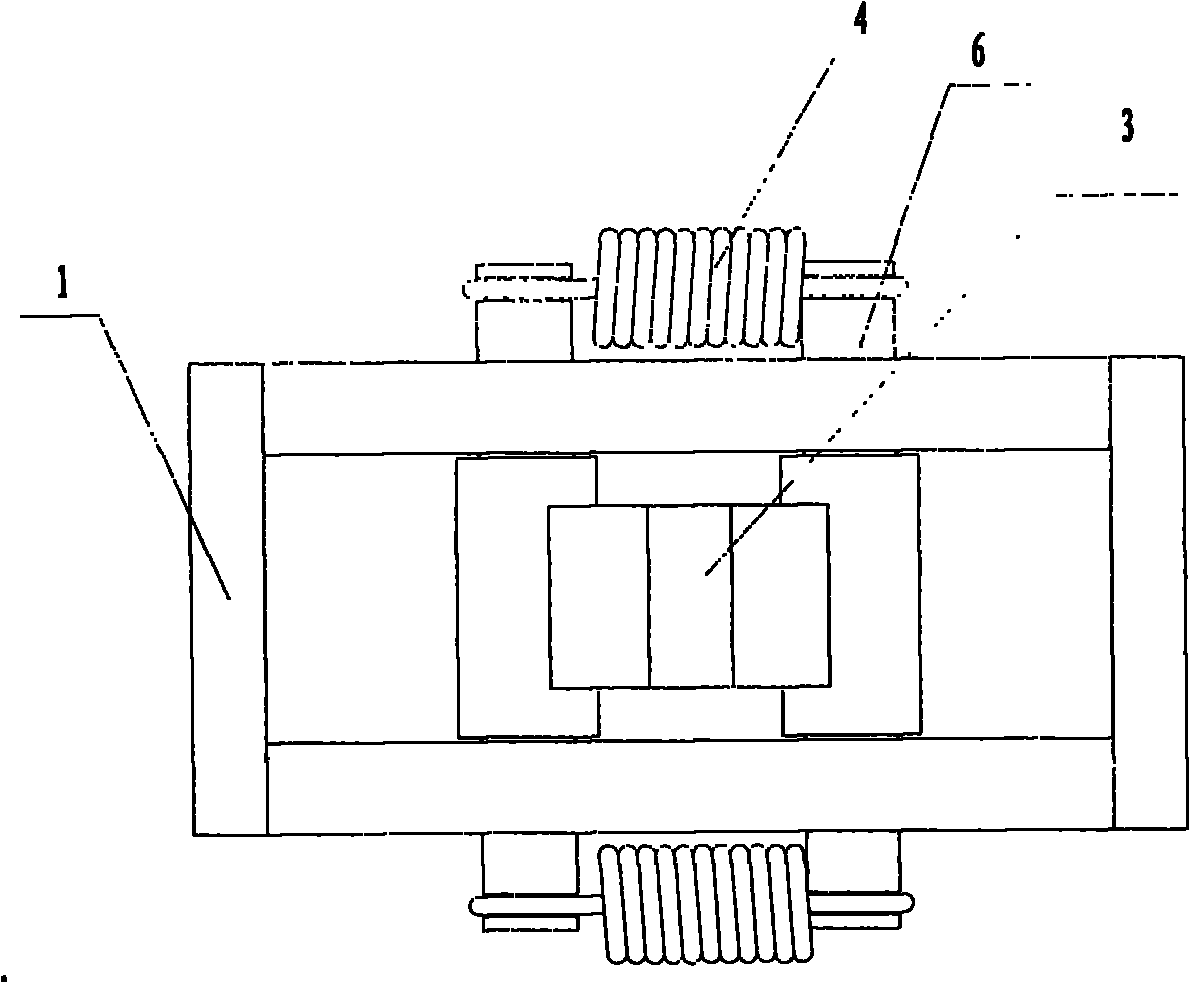

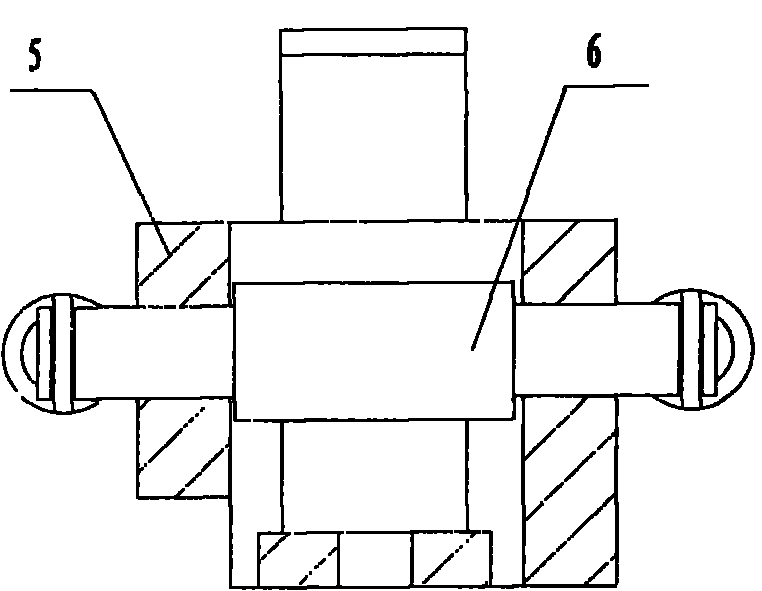

[0011] Such as figure 1 , figure 2 with image 3 As shown, the two ends of the side plates 1 in the pressure beam self-locking mechanism of the upper strap protection device are welded to a left slideway plate 2 and a right slideway plate 5 to form a self-locking square box. The two self-locking shafts 6 are respectively placed in the slideway 7 of the left slideway plate 2 and the right slideway plate 5, and the two ends are connected and tightened by the tension spring 4. The self-locking plate 3 is welded to the supporting base plate 8 and fixed with the upper pressure beam of the broken belt protection device by bolts.

[0012] The working principle is: when the self-locking plate 3 moves up with the upper pressure beam, it hits the self-locking shaft 6, and at this time, the self-locking shaft 6 moves to both sides to open. When the upper pressure beam rises to the limit, the self-locking shaft 6 slides into the self-locking groove in the self-locking plate, tightly locks ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap