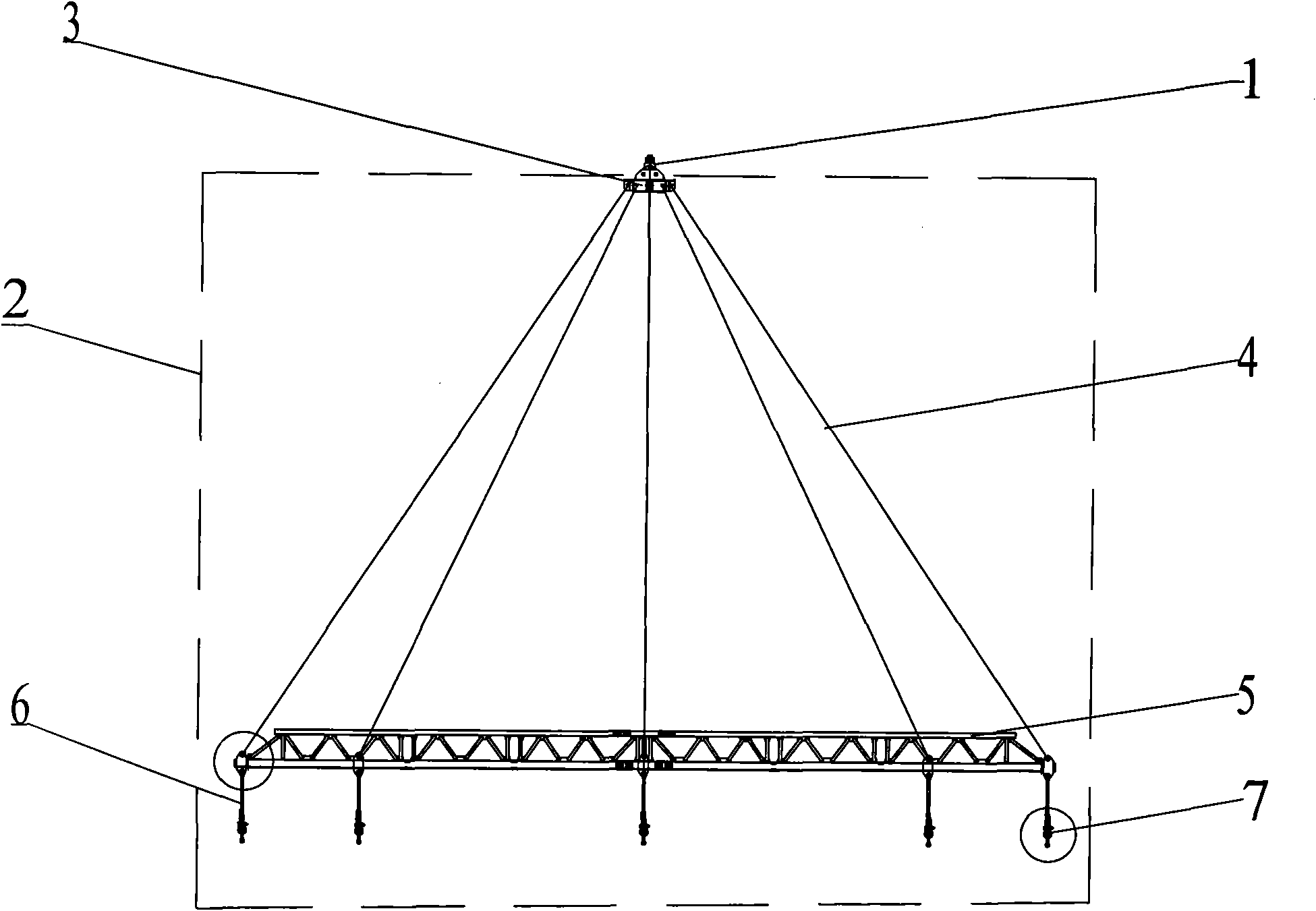

Special lifting tool for steel containment vessel of nuclear power station and lifting method

A technology for steel containment and nuclear power plants, which is used in measuring devices, transportation and packaging, load hoisting components, etc., can solve problems such as hoisting difficulties, and achieve the effects of ensuring hoisting quality and safety, facilitating transportation, and eliminating manufacturing deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

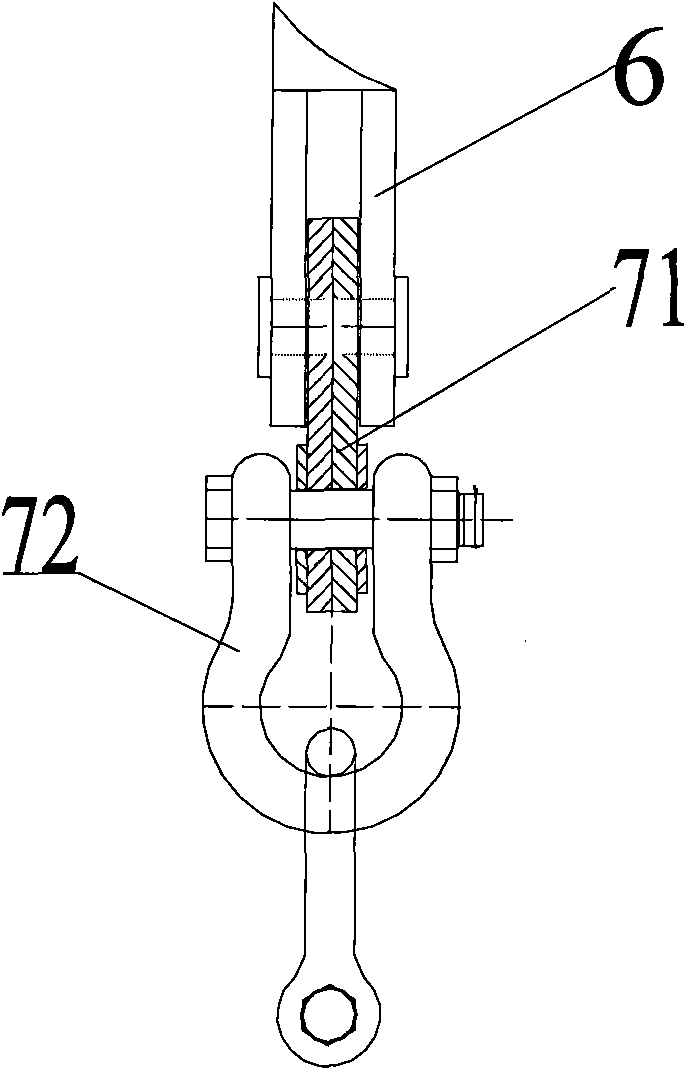

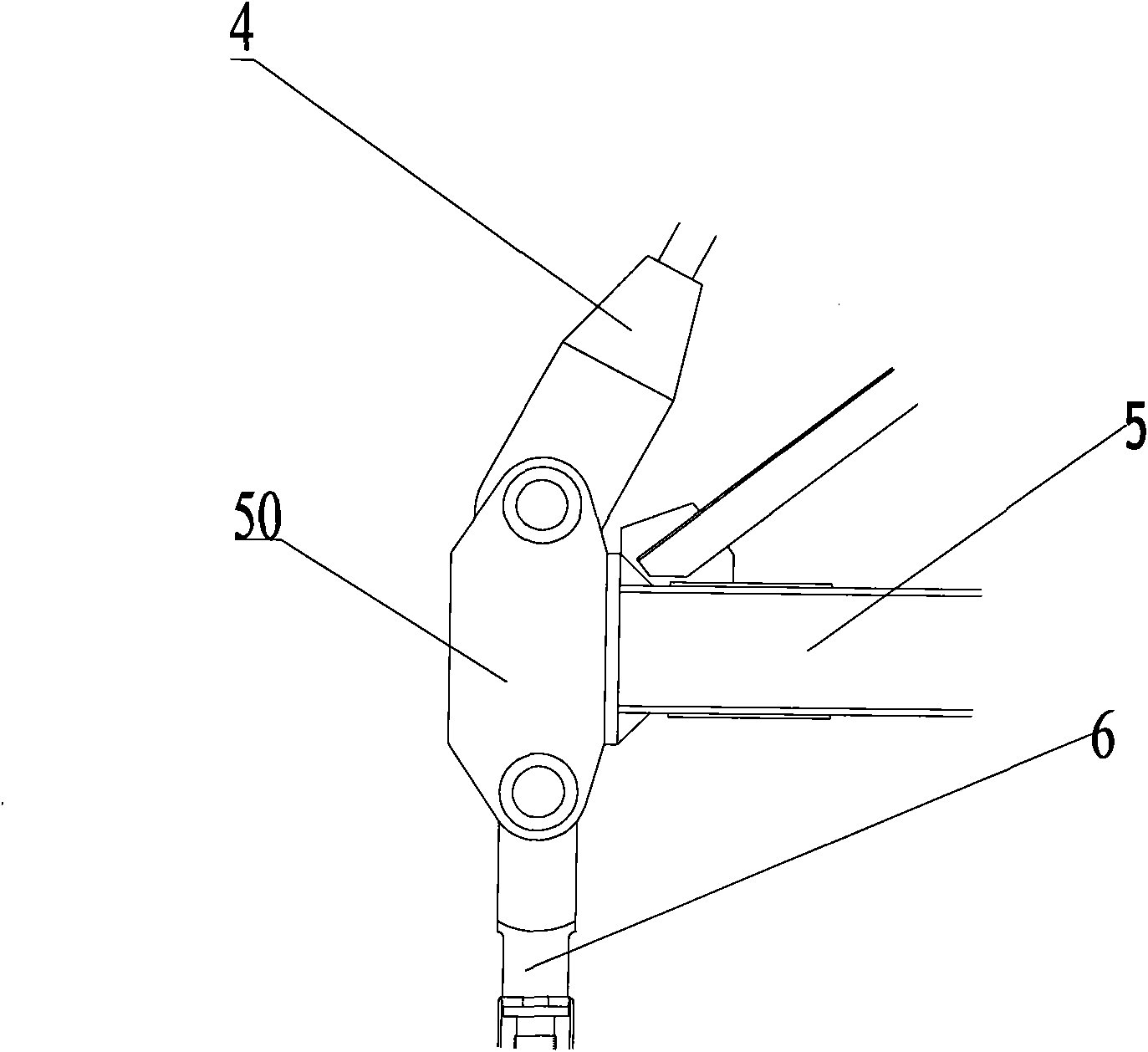

[0047] The most important design of the special spreader for the steel containment of the present invention is that a sling transition beam 3 is arranged in the special spreader 2 . The sling transition beam 3 is composed of four lug plates 31 , an upper cover plate 32 , a connecting plate 33 and a lower cover plate 34 . The lifting lugs 31 are fixed on the upper surface of the upper cover plate 32 and are connected with the hanger 1 of the crane, and the lifting lugs 31 are connected in pairs by reinforcing ribs 35 . The upper cover 32 and the lower cover 34 are fixedly connected by a connecting plate 33 . The connecting plate 33 of the sling transition beam 3 is composed of two through plates 331 and four short plates 332, which are connected to each other to form a "meter"-shaped structure. Through the transition connection of the suspension beam 3, there are eight balanced force points on the suspension beam 5, thereby ensuring the safety of the suspension beam 5 during t...

Embodiment 2

[0050]Another preferred structure of the sling transition beam 3 of the present invention is composed of two lug plates 31 , an upper cover plate 32 , a connecting plate 33 and a lower cover plate 34 . Both lug plates 31 are provided with a pin hole, and the length of the lug plates 31 is the same as the diameter of the upper cover plate 32 . Ribs 35 are also provided on both sides of the lug plate 31 to play a role of stable support. The structure of the connecting plate 33 is the same as the preferred embodiment 1 of the suspension cable transition beam.

[0051] The structural forms of the above embodiments of the suspension cable transition beam are not limiting. On the basis of the above embodiments, the structure of the lug plate 31 and the connecting plate 33 of the sling transition beam can be adjusted according to the structure of the sling attached to the crane.

[0052] Preferred embodiment of hanging beam 1

[0053] In order to evenly distribute the eight stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com