Barium titanate-based thermosensitive resistance material with low B value and high resistivity and preparation method thereof

A thermistor, high resistivity technology, applied in the field of electronic ceramic materials, to achieve the effects of high rated resistance, low preparation cost and excellent sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

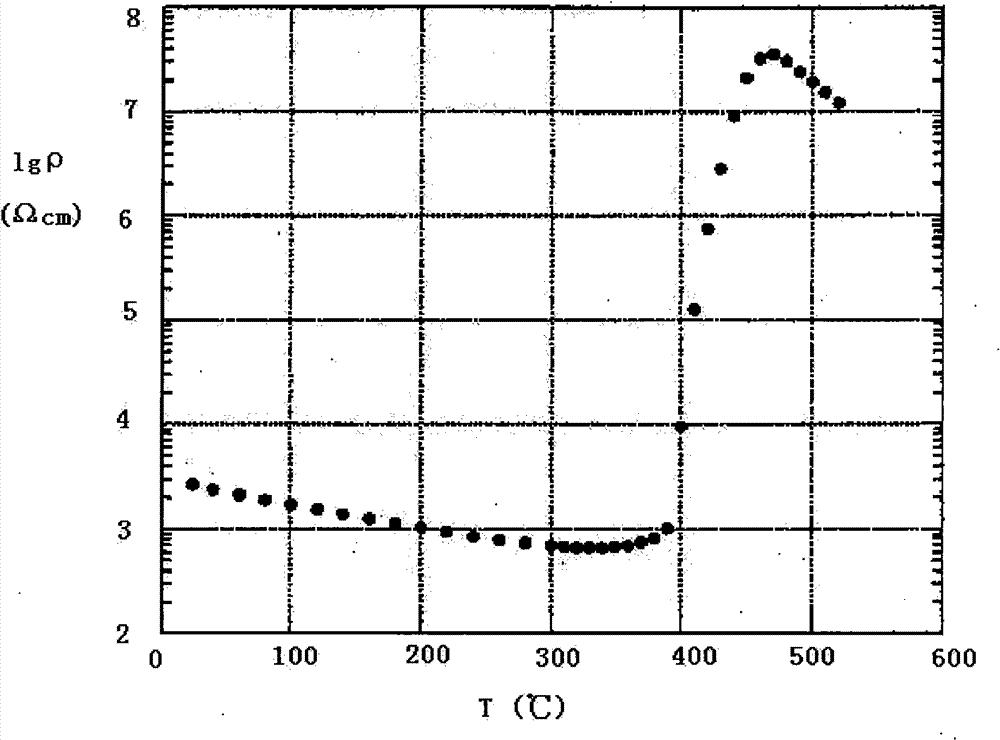

Image

Examples

Embodiment 1

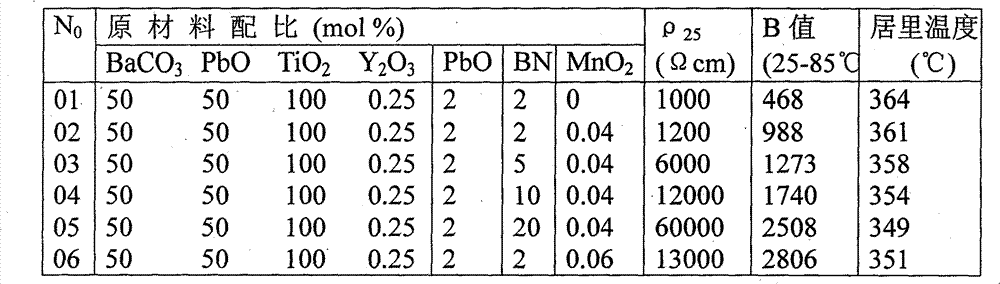

[0021] Embodiment 1: As shown in 1# in table 1, a kind of barium titanate base low B value, high resistivity thermistor material described in the present embodiment is according to chemical general formula:

[0022] (Ba 0.5 Pb 0.5 )TiO 3 +0.25mol% Y 2 o 3 +2mol%PbO+xmol%BN+ymol%MnO 2

[0023] x=2, y=0.00 proportioning, synthesized with the solid-phase reaction method of existing ceramic technology, at first with barium carbonate, titanium dioxide, plumbous oxide, yttrium oxide, boron nitride, manganese oxide as raw material, through weighing proportioning, Remixing, pulverizing with ball mill, drying, pre-burning at 900°C for 2 hours, then ball milling for the second time, adding binder to granulate, forming, and heat preservation at 1200°C for 2 hours, and the sintered sample was electroded, Then the performance parameter test is carried out to obtain the thermosensitive material. The test results are shown in 1# in Table 1.

[0024] Table 1 is the ratio and test resu...

Embodiment 2

[0025] Embodiment 2: as shown in 2# in table 1, present embodiment is similar to embodiment 1, according to general chemical formula:

[0026] (Ba 0.5 Pb 0.5 )TiO 3 +0.25mol% Y 2 o 3 +2mol%PbO+xmol%BN+ymol%MnO 2

[0027] x=2, y=0.04 ratio, synthesized by the solid-phase reaction method of the existing ceramic technology, first with barium carbonate, titanium dioxide, lead oxide, yttrium oxide, boron nitride, manganese oxide as raw materials, through weighing and proportioning, Re-mixing, pulverizing with ball mill, drying, pre-burning at 900°C for 2 hours, then ball milling for the second time, adding binder to granulate, forming, and holding at 1200°C for two hours, and the sintered sample was processed. The electrodes are then tested for performance parameters to obtain heat-sensitive materials. The test results are shown in 2# in Table 1.

Embodiment 3

[0028] Embodiment 3: as shown in 6# in table 1, present embodiment is similar to embodiment 1, according to general chemical formula:

[0029] (Ba 0.5 Pb 0.5 )TiO 3 +0.25mol% Y 2 o 3 +2mol%PbO+xmol%BN+ymol%MnO 2

[0030] x=2, y=0.06 ratio, synthesized by the solid-phase reaction method of the existing ceramic technology, first with barium carbonate, titanium dioxide, lead oxide, yttrium oxide, boron nitride, manganese oxide as raw materials, after weighing the ratio, Re-mixing, pulverizing with ball mill, drying, pre-burning at 900°C for 2 hours, then ball milling for the second time, adding binder to granulate, forming, and holding at 1200°C for two hours, and the sintered sample was processed. The electrodes are then tested for performance parameters to obtain heat-sensitive materials. The test results are shown in 6# in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com