Thermal sensitive ceramic chip, and thermistor and preparation method thereof

A technology of heat-sensitive ceramics and thermistors, used in thermometers with directly sensitive electrical/magnetic components, measuring heat, using electrical devices, etc., can solve problems such as affecting battery life and damaging batteries, achieving strength and Improved material stability, good material uniformity, and uniform powder particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a method for preparing a heat-sensitive ceramic sheet, comprising the following steps:

[0032] ①The mass percentage is: 40%-47% of manganese dioxide, 50%-56% of cobalt tetroxide, 2%-5% of copper oxide, and 1%-4% of titanium dioxide are mixed by solid phase synthesis to obtain initial powder;

[0033] ② Calcining the initial powder at high temperature to form a preliminary spinel structure;

[0034] ③ The powder obtained after calcination is made into the initial green body of the ceramic sheet by pulping, casting, lamination, cutting and other processes;

[0035] ④ Sintering the obtained initial green body of the ceramic sheet to obtain the heat-sensitive ceramic sheet.

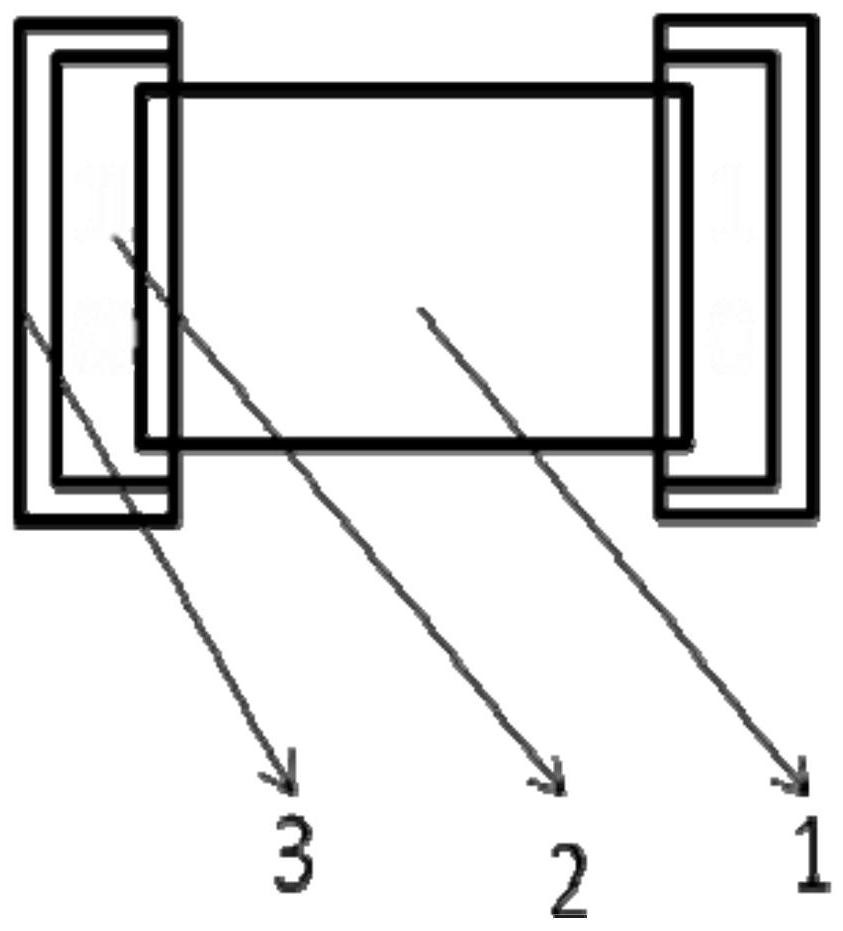

[0036] Such as figure 1 As shown, the embodiment of the present invention also provides a thermistor, including the thermosensitive ceramic chip 1 and a pair of electrodes 2 formed at both ends of the thermosensitive ceramic chip 1 . Preferably...

Embodiment 1

[0053] ① Manganese dioxide, cobalt tetroxide, copper oxide and titanium dioxide are mixed according to the mass percentage of 42%: 53%: 3%: 2% by solid phase synthesis.

[0054] ②Calcinate the mixed powder at 800°C for 6 hours.

[0055] ③ Cut the prepared powder into a rectangular body with a length of 1.80 mm, a width of 0.88 mm and a height of 0.88 m through pulping and casting lamination.

[0056] ④ Sinter the green body at 1150°C to form a heat-sensitive ceramic sheet.

[0057] ⑤ Dip the two sides of the heat-sensitive ceramic sheet in the length direction with silver-coated silver terminal paste with a silver content of 60%-90%, and then sinter at 700°C for 20 minutes to form silver electrodes.

[0058] 6. Plating a nickel layer and a tin layer on the silver electrode by means of electroplating to obtain the thermistor.

[0059] Test and comparison results: The thermistor prepared by the above method has a resistance value of 3.5kΩ at 25°C, a B value of 3900, and a maxi...

Embodiment 2

[0061] ① Manganese dioxide, cobalt tetroxide, copper oxide and titanium dioxide are mixed according to the mass percentage of 44%: 51%: 3%: 2% by solid phase synthesis.

[0062] ②Calcinate the mixed powder at 800°C for 6 hours.

[0063] ③ Cut the prepared powder into a rectangular body with a length of 1.10 mm, a width of 0.58 mm and a height of 0.58 m through pulping and casting lamination.

[0064] ④ Sinter the green body at 1150°C to form a heat-sensitive ceramic sheet.

[0065] ⑤ Dip the two sides of the heat-sensitive ceramic sheet in the length direction with silver-coated silver terminal paste with a silver content of 60%-90%, and then sinter at 700°C for 20 minutes to form silver electrodes.

[0066] 6. Plating a nickel layer and a tin layer on the silver electrode by means of electroplating to obtain the thermistor.

[0067] Test and comparison results: The thermistor prepared by the above method has a resistance value of 8kΩ at 25°C, a B value of 3970, and a maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com