Heat treatment method after forging of ultra-supercritical high and medium pressure rotor steel

A post-forging heat treatment, ultra-supercritical technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of uneven grain size, coarse grains, mixed crystals, etc., and achieve uniform internal and external structures of forgings , Austenitization effect is good, the effect of eliminating forging stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

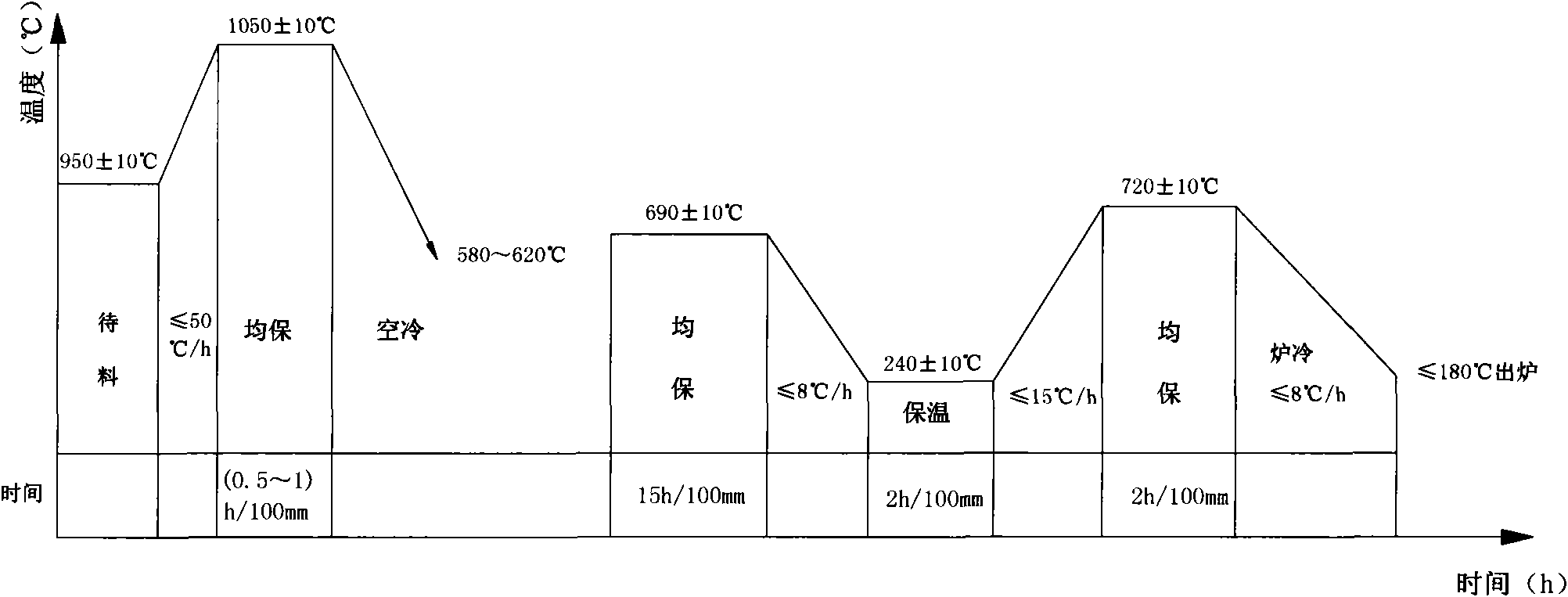

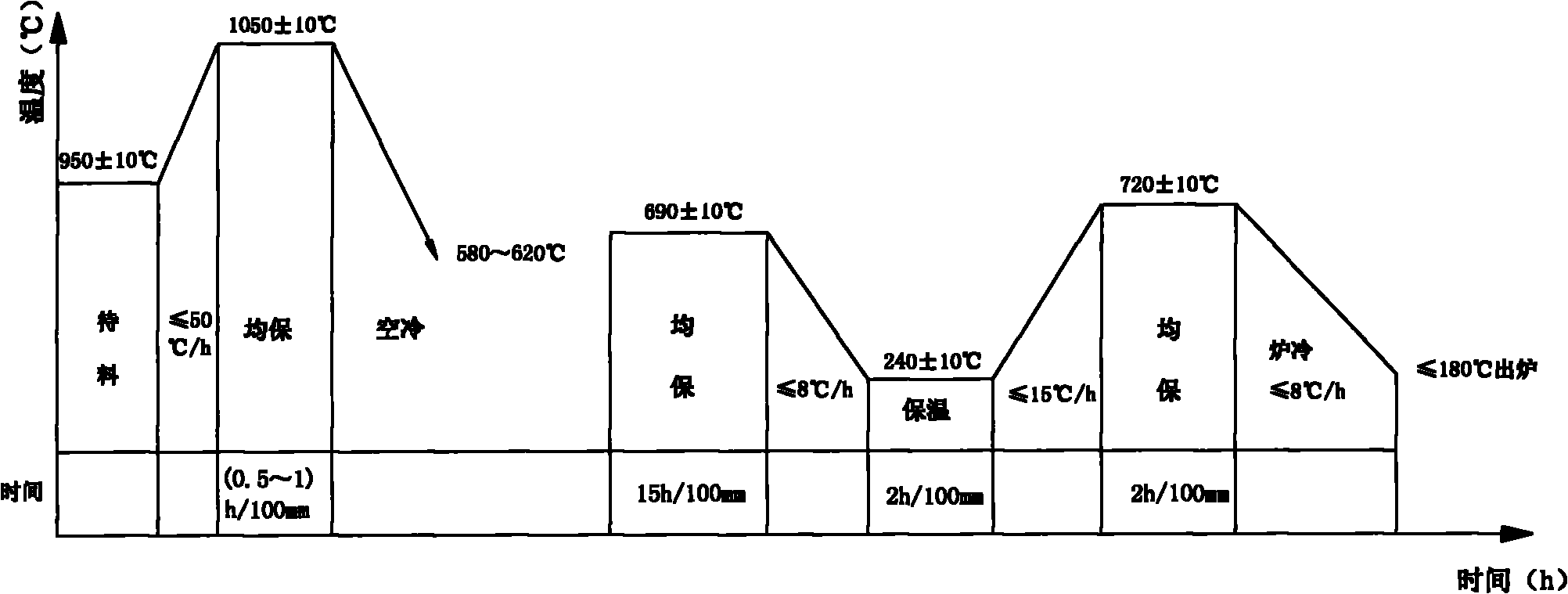

[0017] Such as figure 2 As shown, the post-forging heat treatment method of ultra-supercritical high and medium pressure rotor steel of the present invention adopts the following method to carry out post-forging heat treatment to X12CrMoWVNbN10-1-1 and Cr10.5Mo1W1NiVNbN ultra-supercritical unit high and medium pressure rotor steel:

[0018] The first step, austenite homogenization treatment: After the final forging of the forging is completed (at this time, the temperature of the forging is about 900°C, and the temperature of the core is about 1000°C), without air cooling, the forging is directly placed in a waiting room with a temperature of 950±10°C. Material furnace, heat preservation at a heating rate of ≤50℃ / h to 1050±10℃, and the holding time is 0.5~1h / 100mm (that is, for a forging with a diameter of 100mm, keep it for 0.5~1 hour, and for a forging with a diameter of 1200mm 6 to 12 hours), homogenize the austenite structure, eliminate the forging stress, adjust the grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com