OLED (Organic Light Emitting Diode) mask and application method thereof

A technology for masks and vapor deposition materials, applied in the field of masks, can solve the problems of decreased production efficiency, increased equipment processing time, increased masks, etc., and achieves improved production efficiency, simplified equipment structure, and the number of masks. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

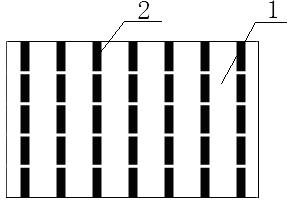

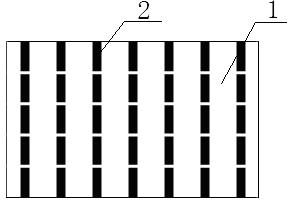

[0018] see figure 1 , 2, 3, a kind of OLED mask board, described mask board is horizontally provided with odd column groove group; Described groove group is made up of the groove arranged vertically; The distance between the groove group on the mask board is two Groove width; the distance between the nearest groove group from the transverse edge of the mask plate is one groove width.

[0019] Based on the application method of the OLED mask,

[0020] (1) In the same evaporation chamber, set the green evaporation material, red evaporation material and blue evaporation material in different evaporation units, and turn off the green evaporation material, red evaporation material and blue evaporation Evaporation unit baffles for materials;

[0021] (2) Align the mask plate with the substrate;

[0022] (3) Open the baffle plate of the green evaporation unit to conduct e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com