Road surface milling machine

A milling machine and milling technology are applied in the field of road milling machines, which can solve the problems such as difficulty in controlling the walking speed of the road milling machine, increase the labor intensity of operators, and harsh working environment of the milling machine, and achieve compact structure and improved performance. The effect of working reliability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

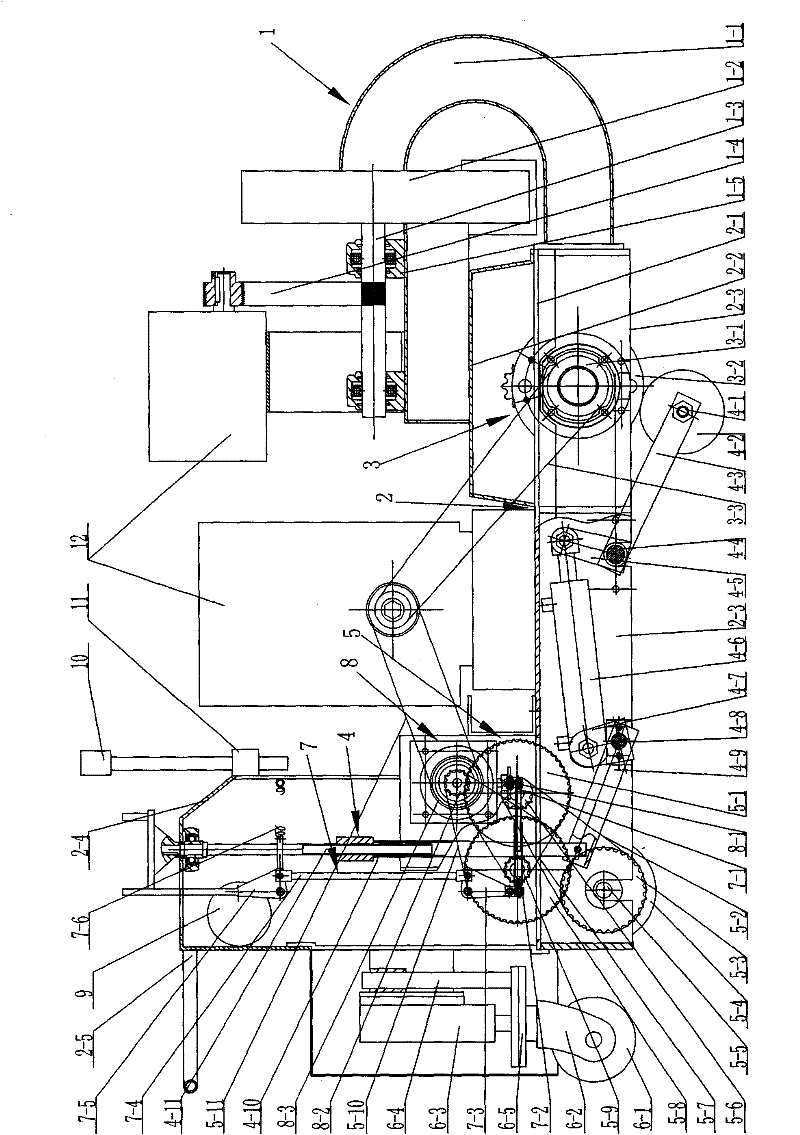

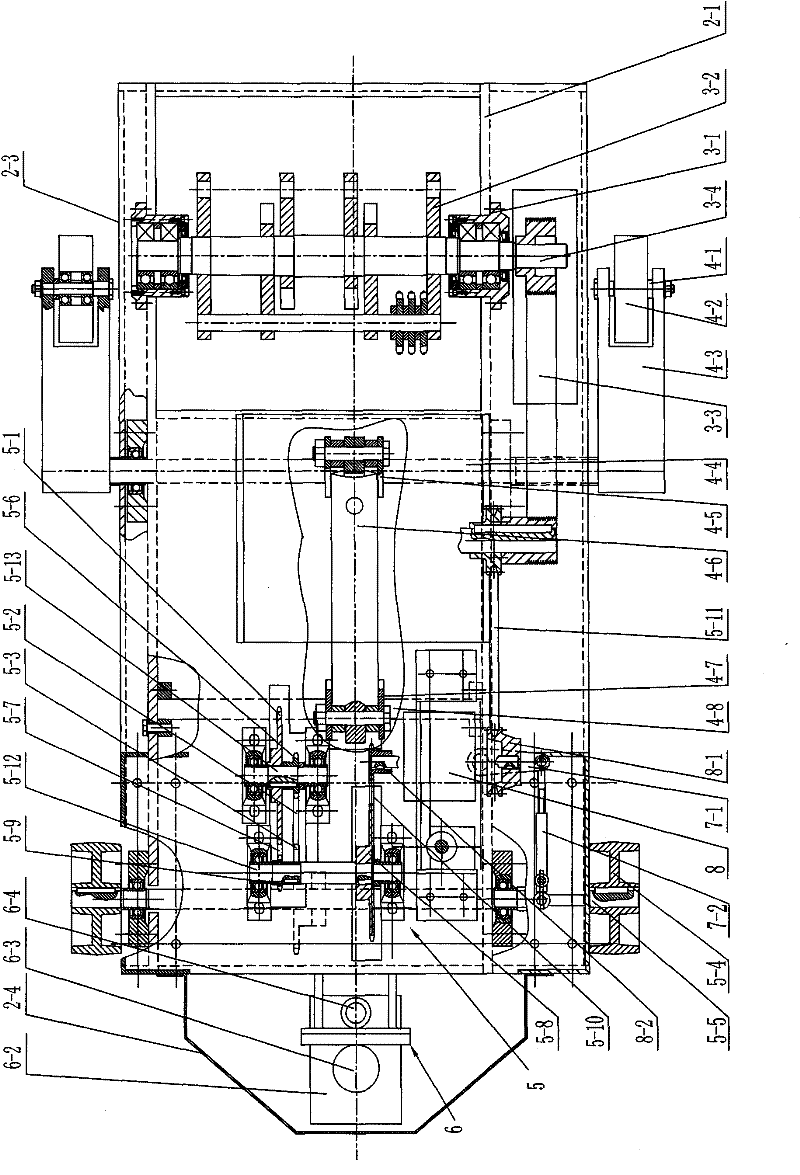

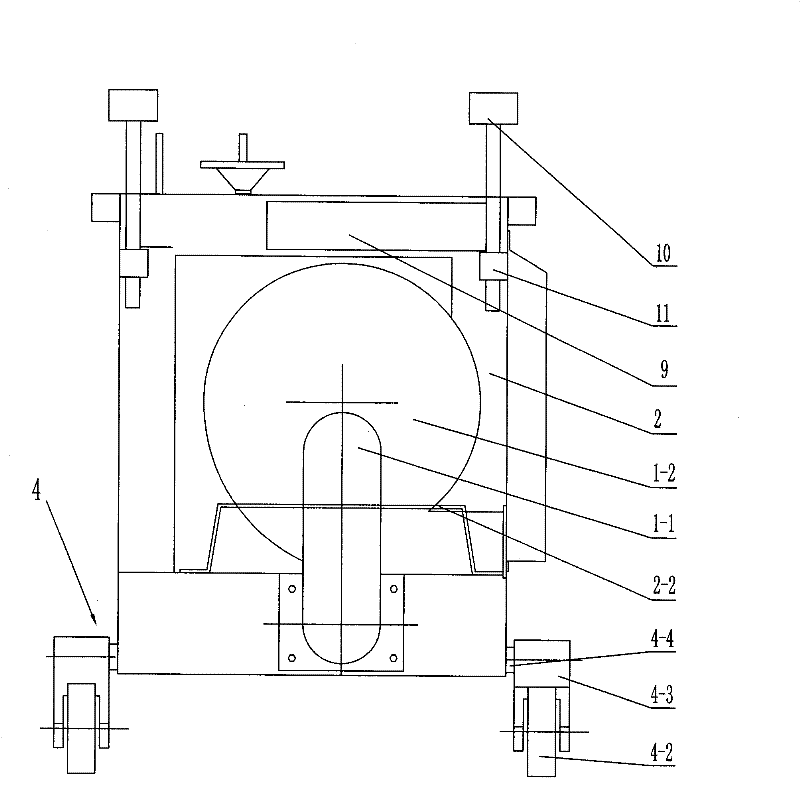

[0017] See Figure 1~5 As shown, the road milling machine of the present invention includes an engine 12 installed on a vehicle frame 2, a milling device 3, a walking device 5, a supporting lifting device 4 and a dust collection device 1. See figure 1 , 2 As shown, the vehicle frame 2 of the present invention comprises a chassis 2-1 and a machine base 2-4 fixed on the chassis 2-1, the chassis 2-1 is welded into a frame structure by crossbeams and longitudinal beams, and the periphery of the chassis 2-1 has Coaming board 2-3, support 2-4 are installed on the chassis 2-1, and the rear portion of support 2-4 is equipped with handrail 2-5, and the operator supports milling machine conveniently. Milling device 3 of the present invention comprises the milling drum 3-2 that milling cutter is housed, and multiple groups of milling cutters are installed on the milling drum 3-2 according to the law, can adopt 3-9 milling cutters to be installed on the milling drum 3-2, The drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com