Air intake and noise reduction system

A noise reduction system and air intake technology, applied in air cooling, engine components, machines/engines, etc., can solve the problems of unsatisfactory wind resistance, large flow, unsatisfactory sound insulation effect, etc., and achieve significant noise reduction effect, noise reduction, structure Well-planned effect

Inactive Publication Date: 2010-09-15

河南宜和城保装备科技实业有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the existing air intake and noise reduction structures are provided with a plurality of oblique air intake and noise reduction grids at the air inlet. The space is still directly connected to the outside world through the air intake noise reduction grid or bypass, so the sound insulation effect is not ideal. The wind resistance and large flow are not ideal, and the noise has a significant impact on the outside world.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

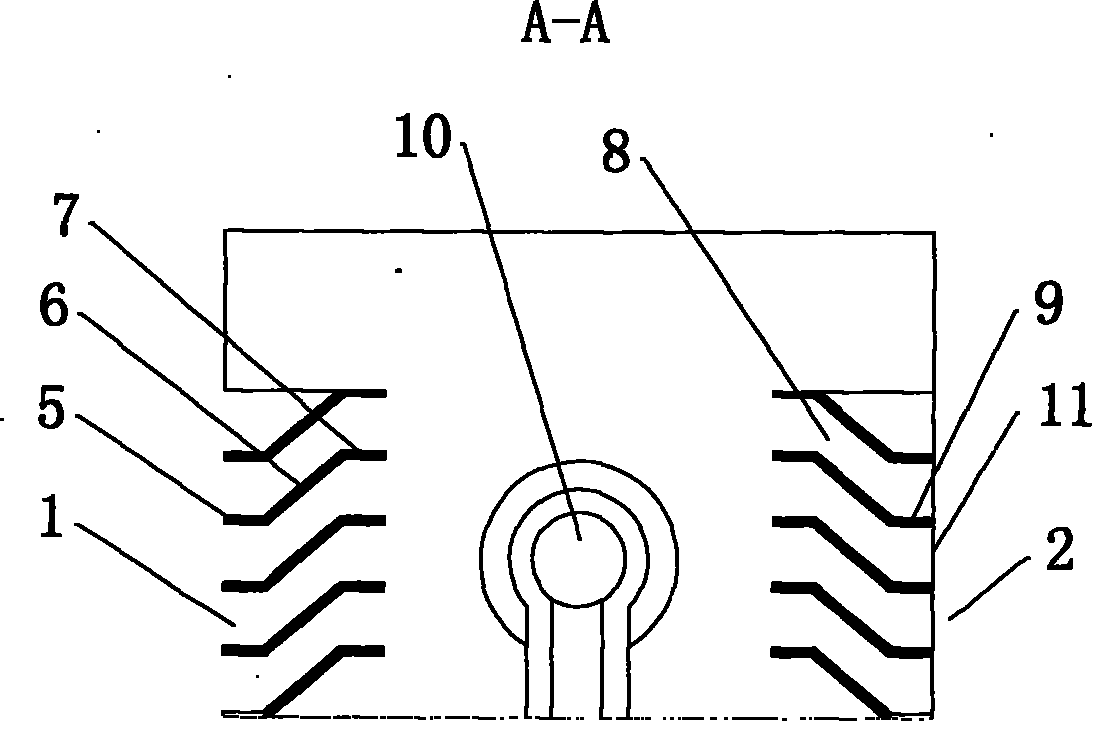

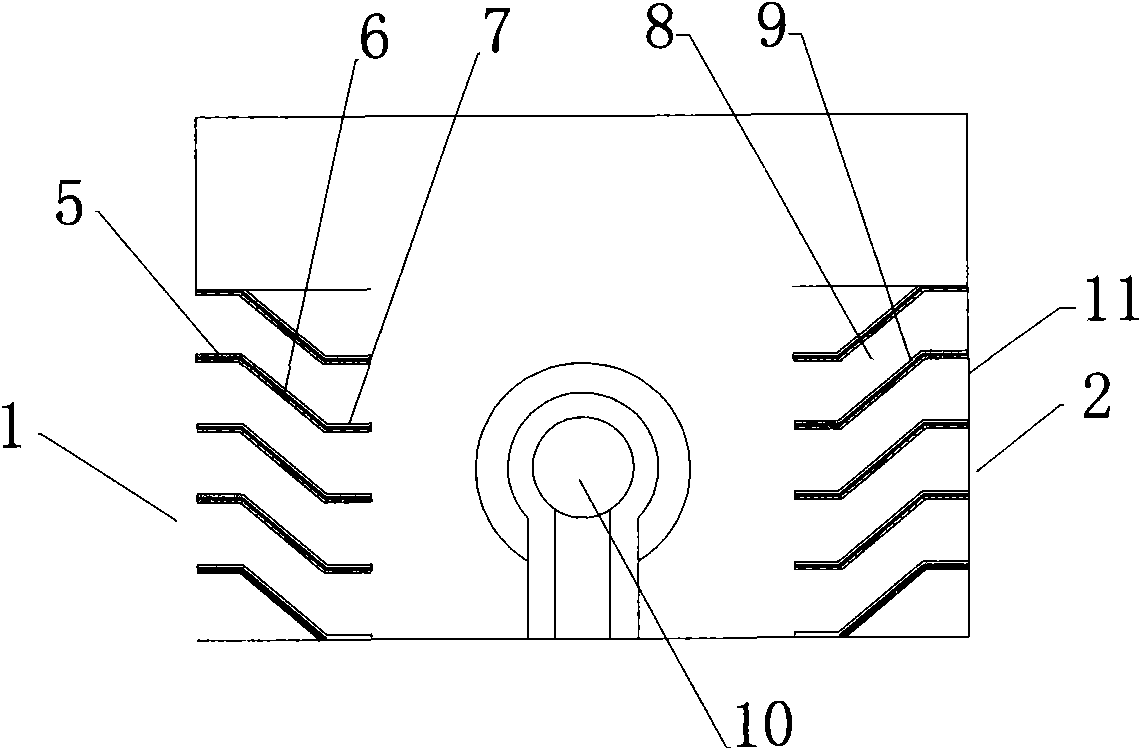

The invention discloses an air intake and noise reduction system, which is used for providing air for burning and cooling for a generator set (comprising engines and generators) in a sealed space. The air intake and noise reduction system comprises an air intake path which is arranged on bodies at two sides of the generator set, and a noise reduction grid is arranged in the air intake path. The air intake and noise reduction system is characterized in that the air intake and noise reduction grid is provided with a first horizontal section and a second horizontal section, wherein an inclined section is connected between the first horizontal section and the second horizontal section, and the noise reduction grid causes the air intake path to form a plurality of paths. Compared with the prior art, the invention has simple structure and can improve noise reduction effect, noise in the compartment is reduced to about 65 decibels (the noise value on the position far away from the air intake port for 1m) from original 100 decibels so as to totally conform to the environment protection requirements on equipment noise, and the purpose of improving working environment is realized.

Description

technical field The invention belongs to the technical field of power equipment, and in particular relates to an intake air noise reduction system that provides air for combustion and cooling to a generating set (including an engine and a generator) in a confined space. Background technique In the known technology, diesel or non-diesel generator set is used as a power source for maintenance or power distribution in the field without electricity and when the power is cut off. When the generator set is working, the noise is particularly loud and affects the surrounding environment. In order to reduce the noise, it Set up in a compartment or in a separate room such as a power cart. Since the box body or room is also provided with an air intake channel for combustion and cooling air, the noise of the generator set will also transmit noise through the air intake channel. Most of the existing air intake and noise reduction structures are provided with a plurality of oblique air i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F01P1/00

Inventor 孙健军王书聚杨晨宇

Owner 河南宜和城保装备科技实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com