Sealing structure of industrial oil-free reciprocating labyrinth compressor piston rod

A sealing structure and piston rod technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of contaminating lubricating oil, increasing the cost of use, unable to effectively seal the liquid high-carbon condensate, etc. The effect of reducing the cost of use and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

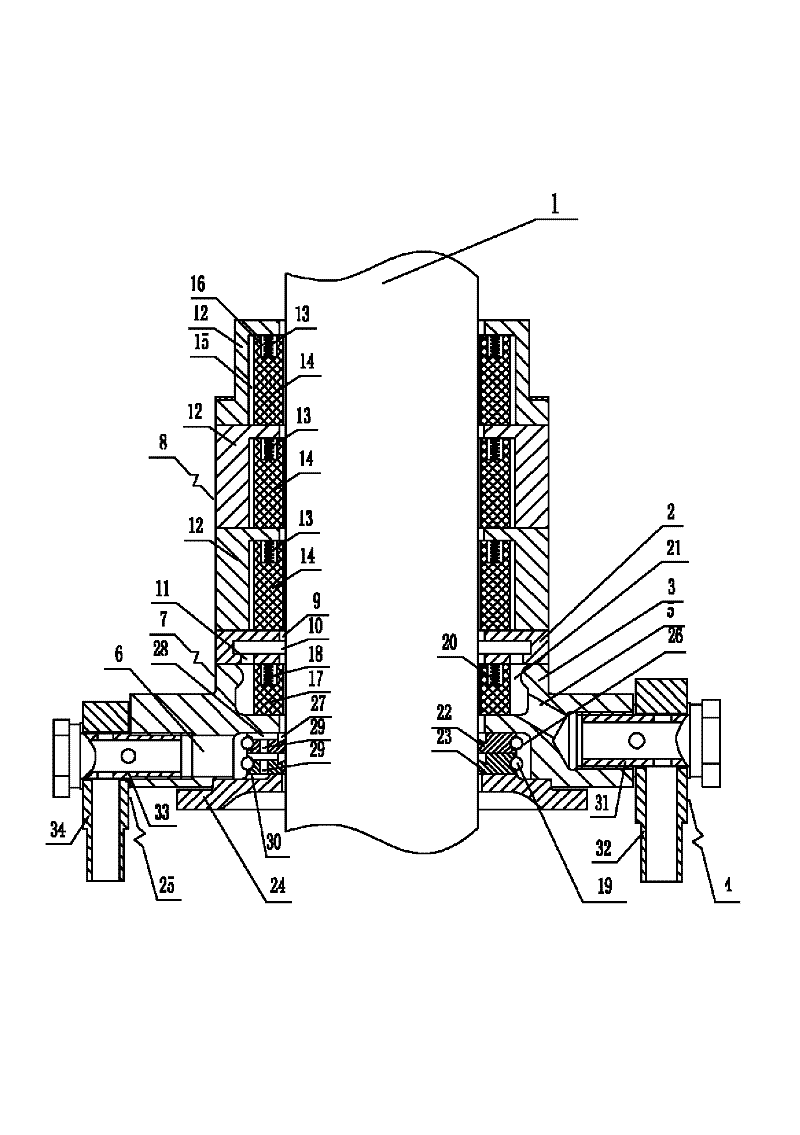

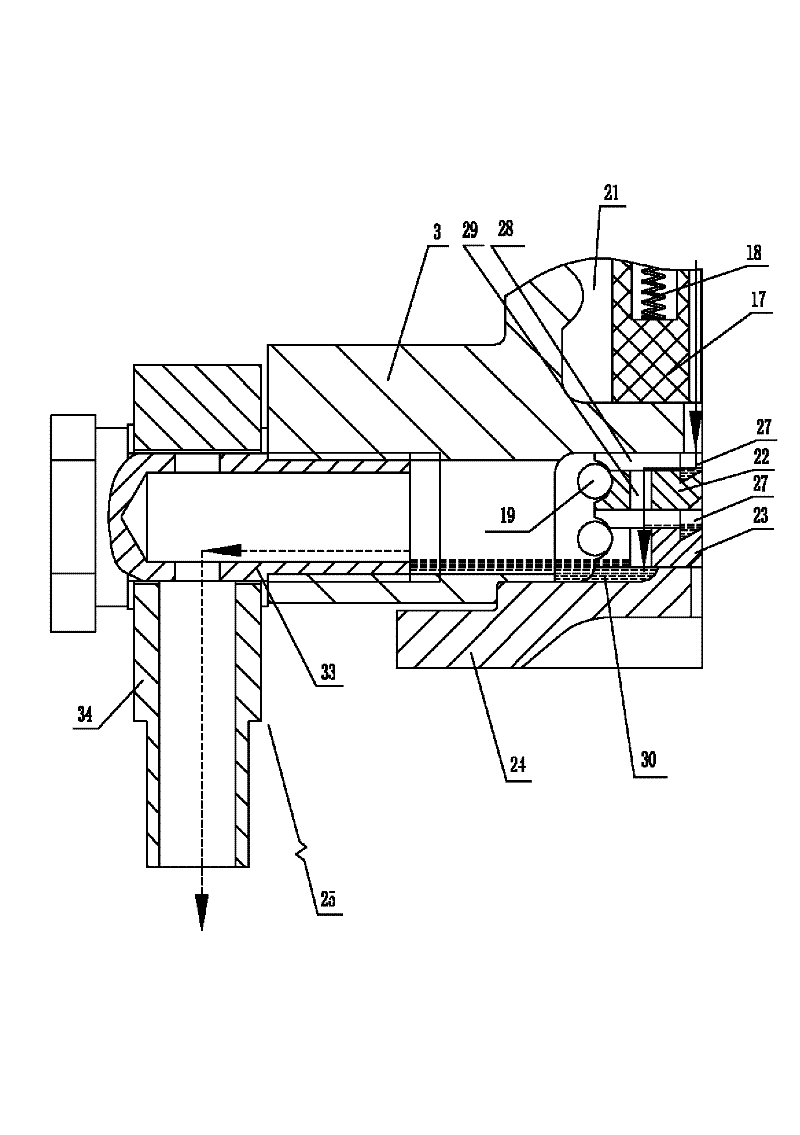

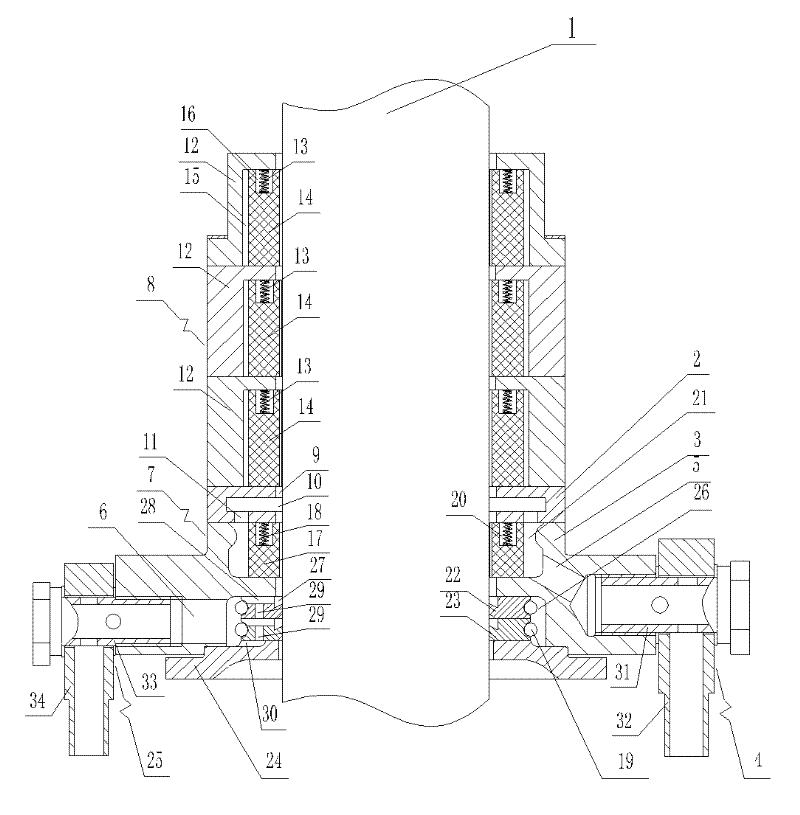

[0020] See figure 1 , figure 2 , which includes a piston rod 1 and a process air sealing system, the process air sealing system is set on the outer edge of the piston rod 1, the lower part of the process air sealing system is connected with a scraper oil collection system, and the scraper oil collection system is set on the outer edge of the piston rod 1;

[0021] The process gas sealing system specifically includes four packing seals and leakage gas discharge channels, spacer ring 2, discharge gland 3, gas outlet hinged pipe joint 4, discharge gland 3 includes gas outlet pipeline 5, oil outlet pipeline 6, gas outlet pipeline 5, The oil outlet pipes 6 are located inside the two sides of the discharge gland 3 respectively. Four packing seals and leakage gas discharge passages are arranged from top to bottom and fitted on the outer edge of the piston rod 1. The lowermost packing seal and leakage gas discharge passages 7 The upper end surface is supported by a distance ring 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com