Quick valve connecting device for gas-fired equipment

A quick connection and valve technology, which is applied in the field of connection devices connecting gas circuits between control valves and quick connection devices for valves used in gas equipment, can solve problems such as inconvenient installation and improper connection, and achieve convenient connection, maintenance and replacement, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

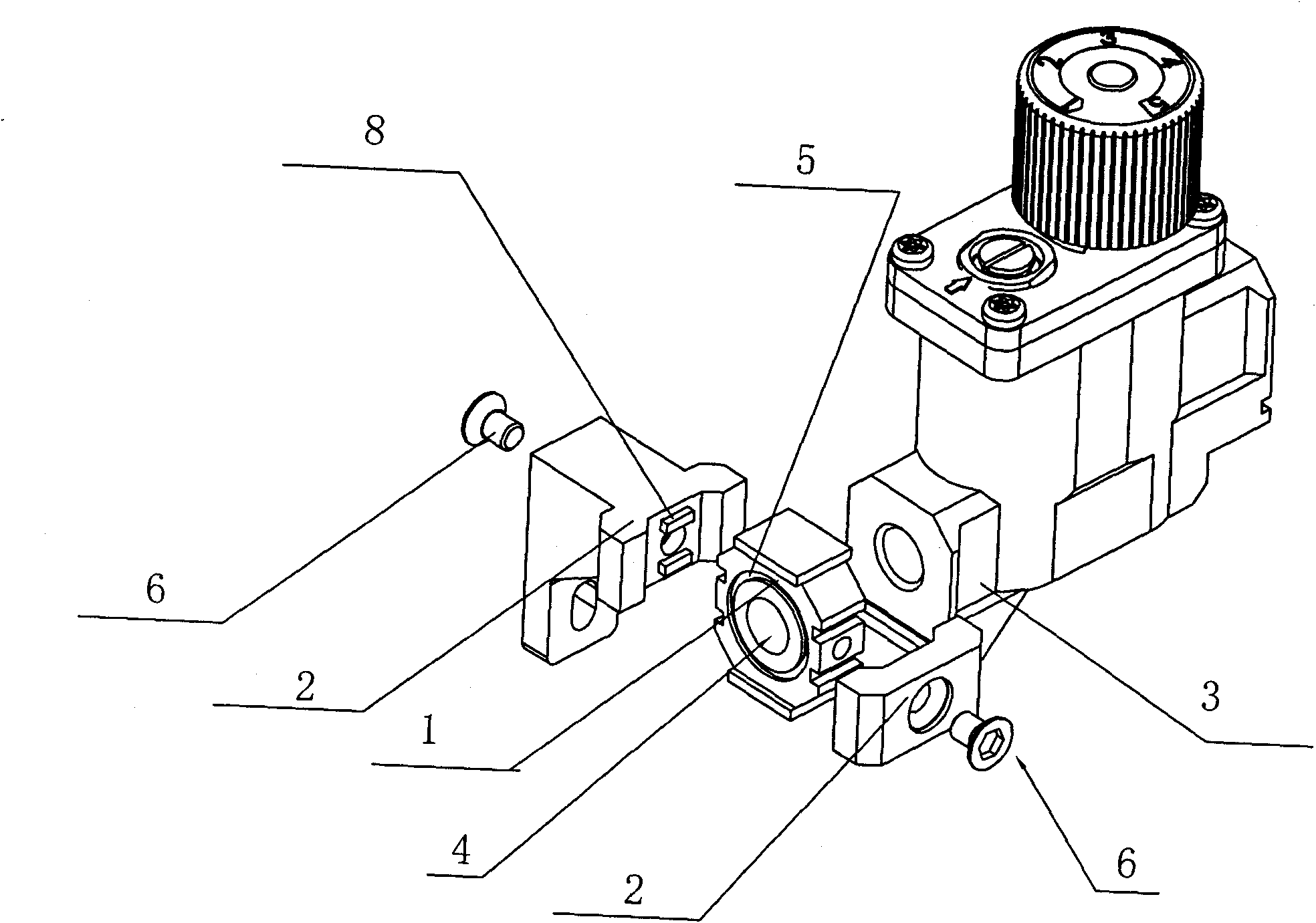

[0023] Such as figure 1 shown.

[0024] A valve quick connection device for gas equipment, which is mainly composed of a connecting piece 1 and two fastening pieces 2. The upper bottom surface or the lower bottom surface of the connecting piece 1 can be designed as a plane shape. From the perspective of reliable connection, the two fastening pieces Parts 2 can be respectively located on the front and rear surfaces or the upper and lower surfaces of the connecting part 1. The shapes or safety of the two fasteners 2 are the same, and there may be certain differences, but the principle of fastening is the same. The connecting piece 1 is located between the corresponding air inlets or outlets of the two valves 3 to be connected, and the connecting piece 1 is provided with a through hole 4 communicating with the air inlet or outlet between the two valves 3 to be connected. The two ends opposite to the air inlet or outlet of the connected valve 3 are provided with a ring groove 5 f...

Embodiment 2

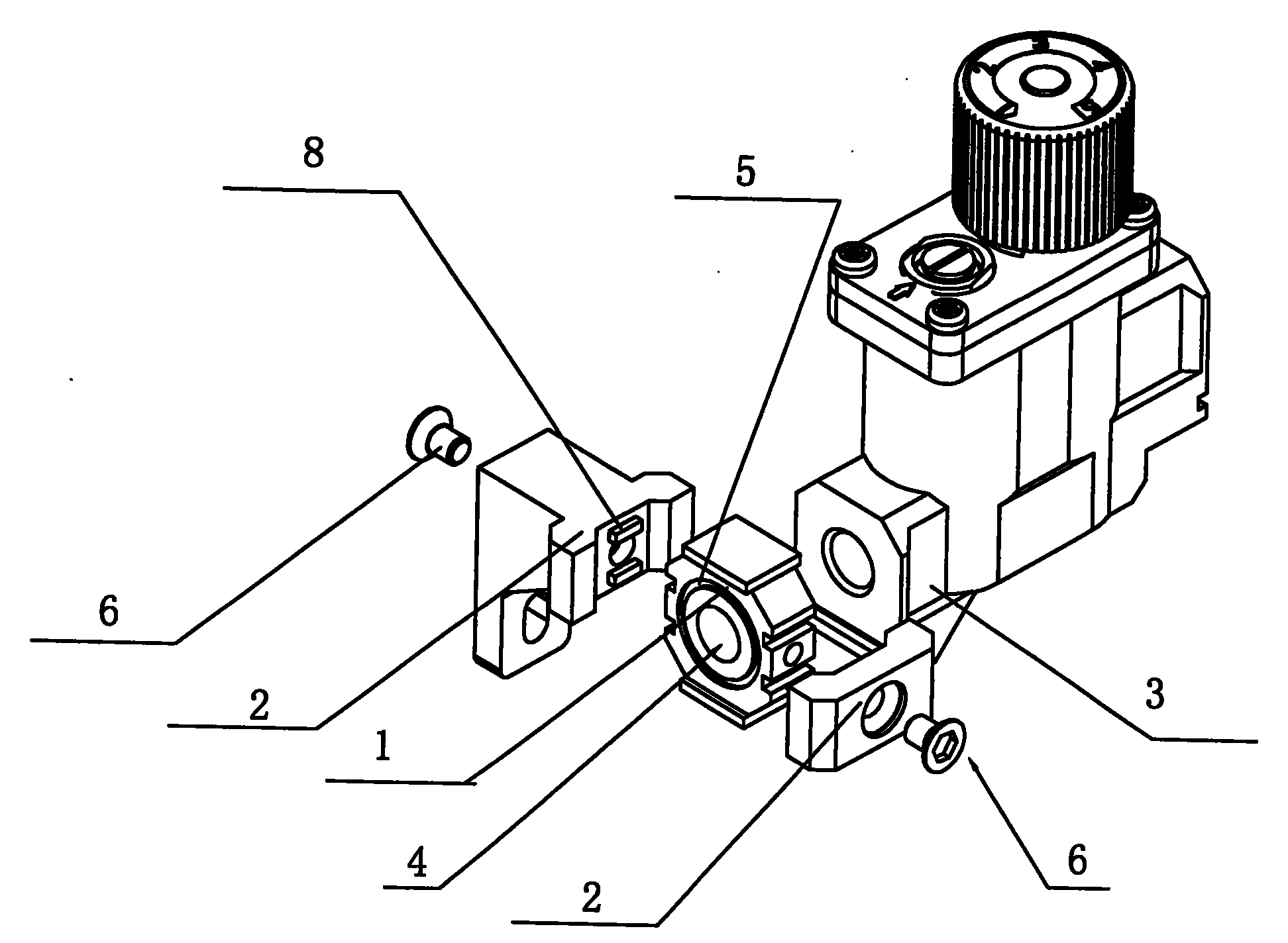

[0027] Such as figure 1 shown.

[0028] The difference between this embodiment and the first embodiment is that only one fastener 2 is used to cooperate with the pin or pin hole on the end surface of the connector 1 to cooperate with the pin hole or pin on the valve to achieve a reliable connection. That is, the two ends of the connector 1 are provided with pins or pin holes matching the end faces of the air inlet or air outlet of the valve 3, and the end faces of the air inlet or air outlet of the valve 3 are provided with pin holes or pins.

Embodiment 3

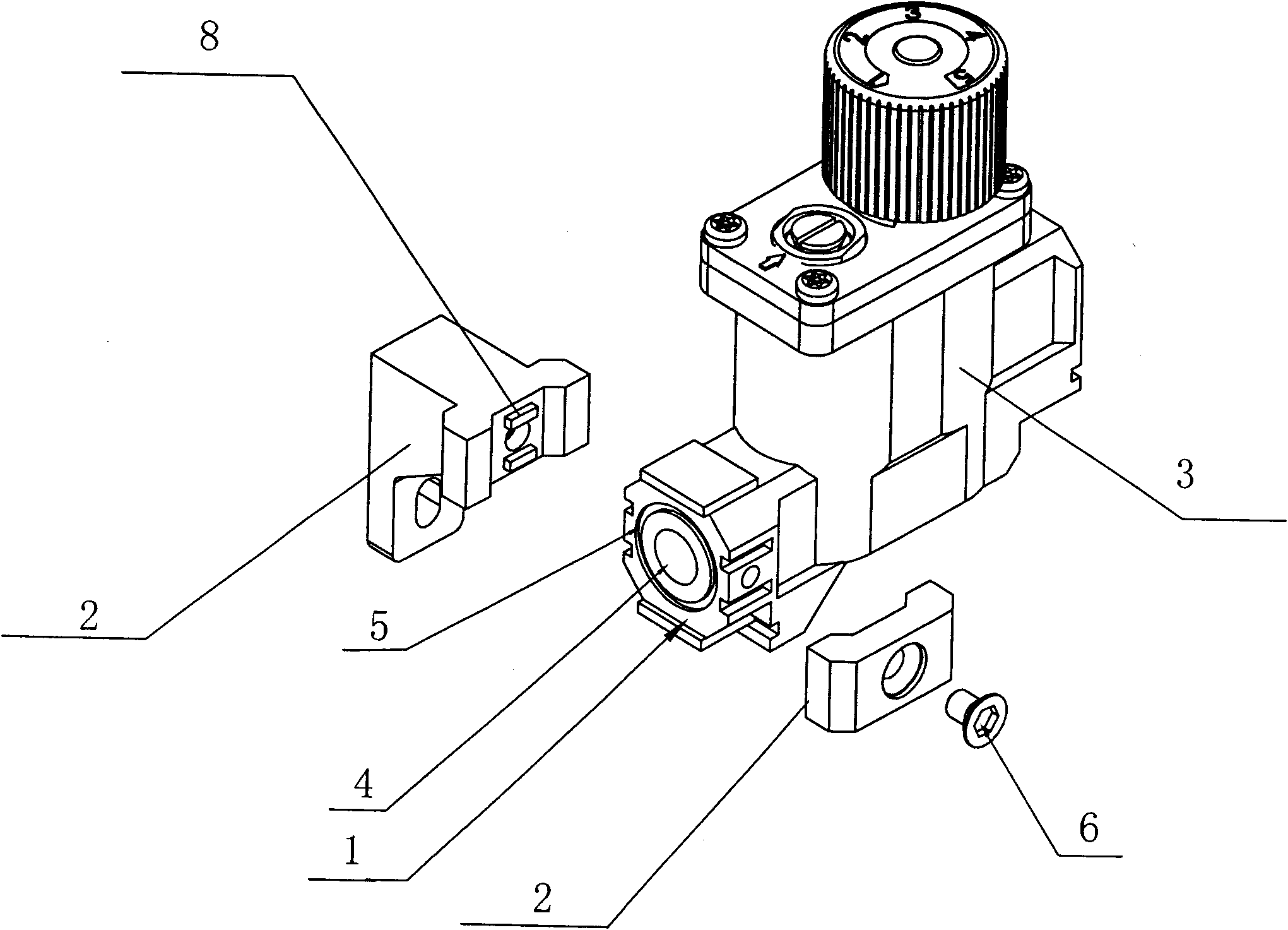

[0030] Such as figure 2 shown.

[0031] The difference between the present embodiment and the first embodiment is that the connecting piece 1 is directly fixed on the valve 3 to be connected. At this time, it is only necessary to install a sealing ring on the outer end surface of the connecting piece 1, and there is no need to process ring grooves 5 on both sides. During specific implementation, the two valves 3 that need to be connected can all have the connecting piece 1, and the span of the tightening part 2 should be made larger at this moment, or only one of the valves 3 has the connecting piece 1, and the Another valve 3 has the same structure as the first embodiment. The rest are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com