Insert device with exhausting function

A ferrule body and ferrule technology, applied in the coupling of optical waveguides, etc., can solve the problems of air, insertion loss maintenance, and cleanliness, etc., and achieve the effect of simple structure, convenient operation, and reduced loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

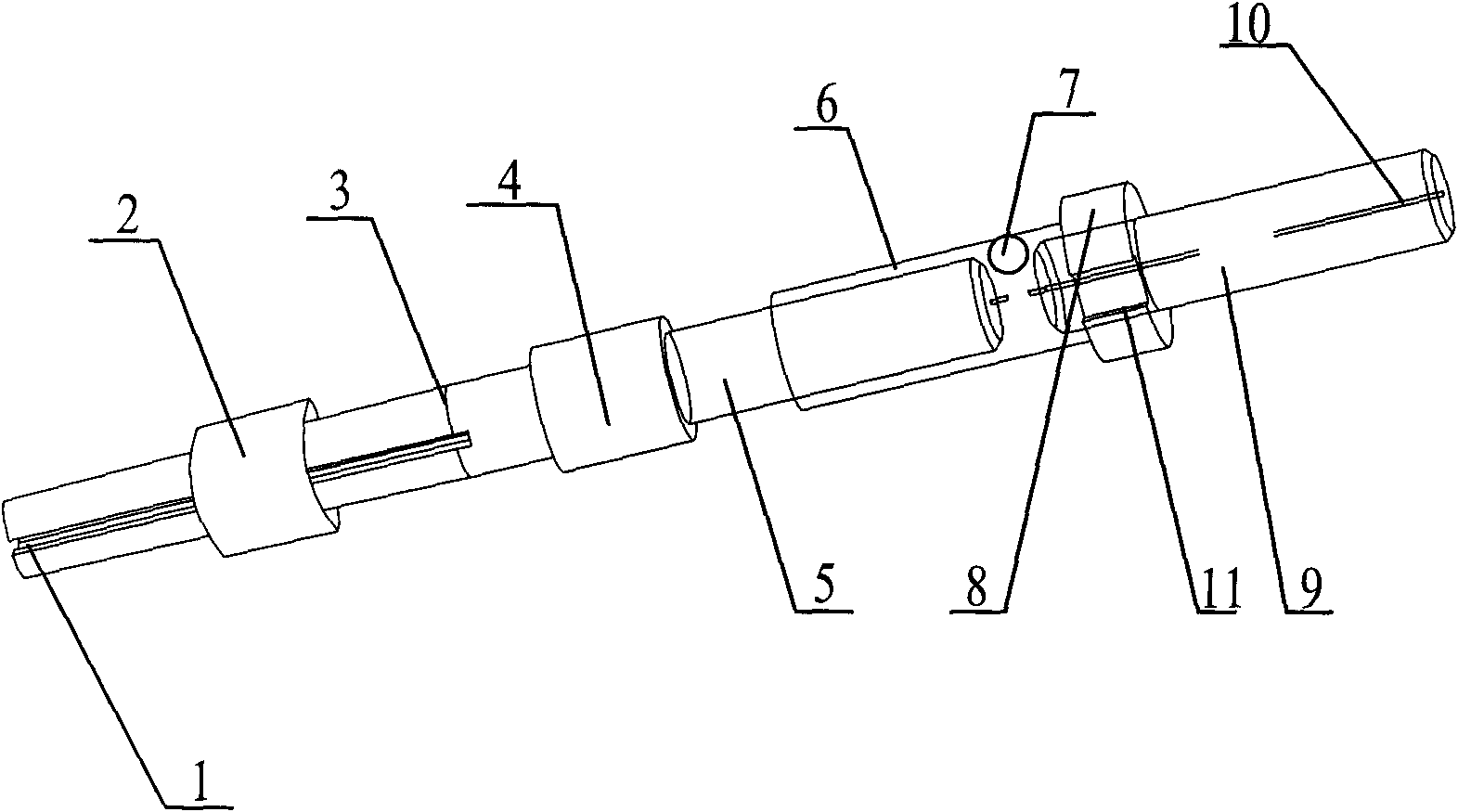

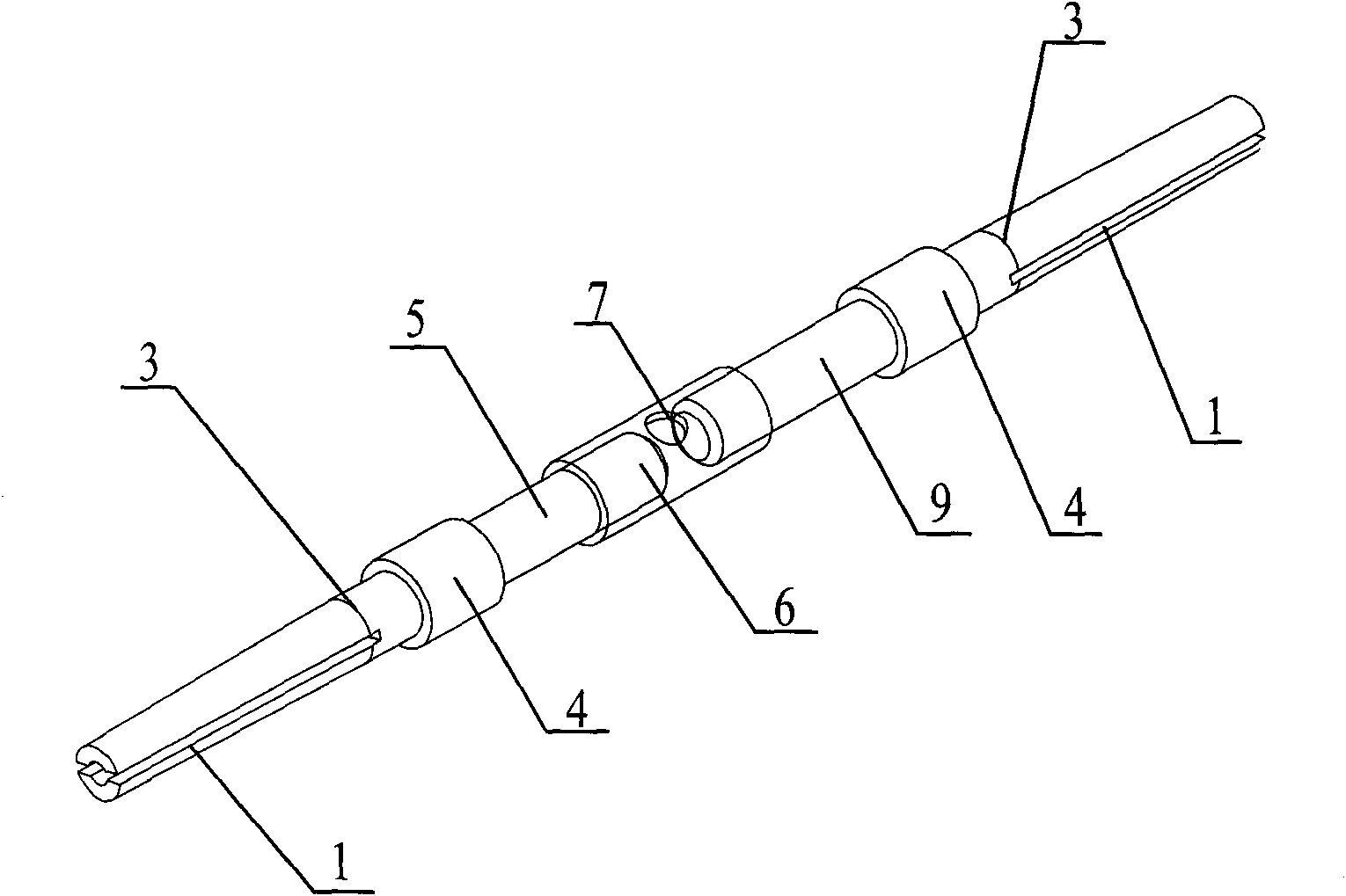

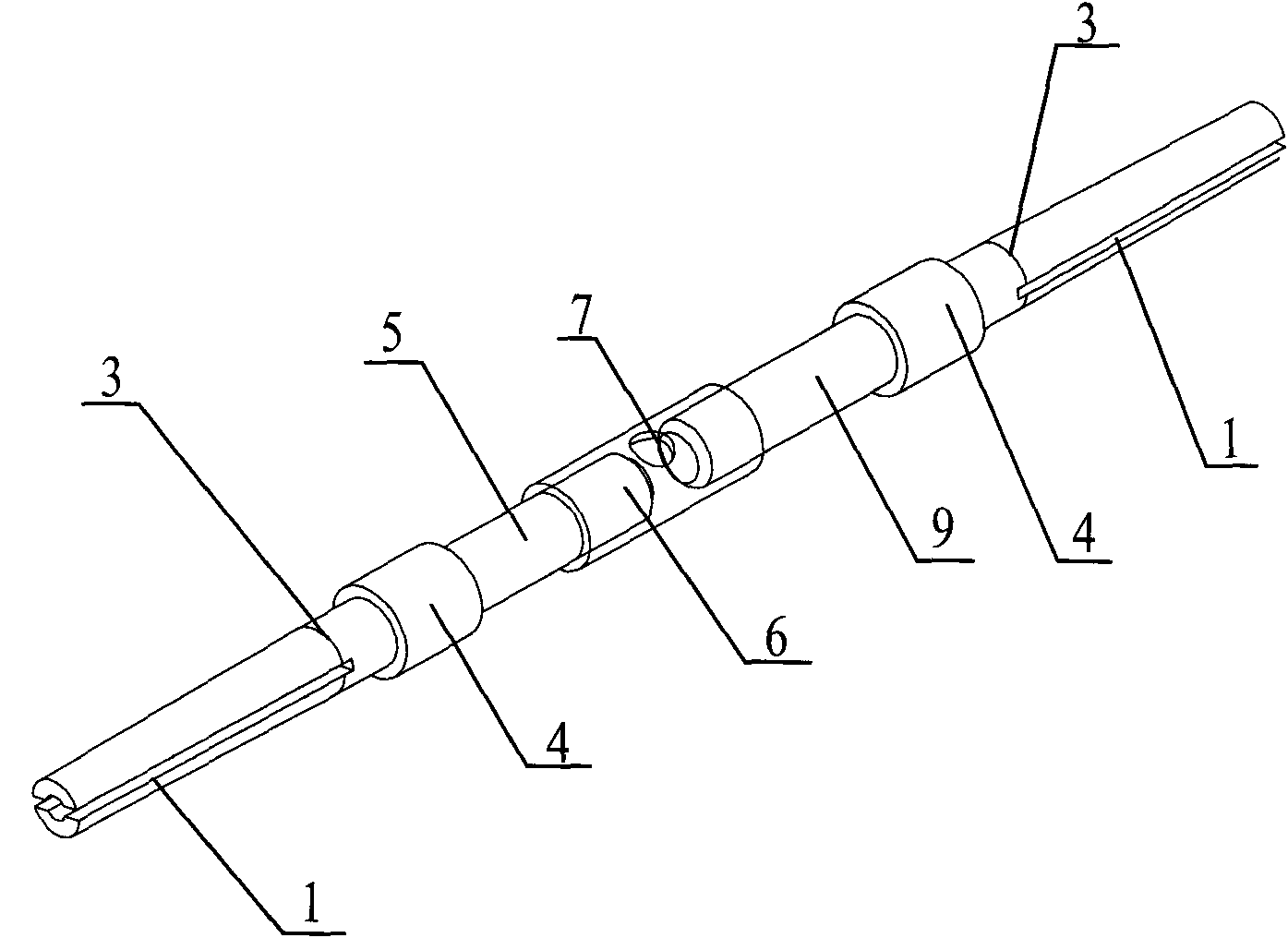

[0013] Such as Figure 1 ~ Figure 2 As shown: the present invention includes a slot 1, a crimping ring 2, a ferrule tail handle 3, a positioning block 4, a first ferrule 5, a connecting pipe 6, an exhaust hole 7, a limiting block 8, and a second ferrule 9 , optical fiber 10 and groove 11.

[0014] Such as figure 1 As shown: the two ends of the connecting pipe 6 are respectively provided with a first ferrule 5 and a second ferrule 9; one end of the second ferrule 9 extends into the connecting pipe 6 and is fixedly connected with the connecting pipe 6 ; The end of the connecting tube 6 corresponding to the second ferrule 9 is provided with an optical fiber matching liquid, and the optical fiber matching liquid surrounds the end of the second ferrule 9, and the connecting tube 6 is provided with a fiber matching liquid corresponding to the side wall provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com