High specific capacitance capacitor cathode foil and film coating apparatus manufacturing the same

A coating device and capacitor technology, applied in capacitor manufacturing, capacitors, electrolytic capacitors, etc., can solve the problems of large loss value, large negative electrode foil, and high manufacturing cost, and achieve low impedance and loss, good thermal stability, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

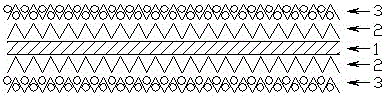

[0013] see first figure 1 The high specific capacitance negative electrode foil of the present invention has an aluminum foil 1, a titanium nitride layer 2 is sputtered on the surface of the aluminum foil 1, and a mixed layer 3 of titanium nitride and graphite is sputtered on the surface of the titanium nitride layer 2.

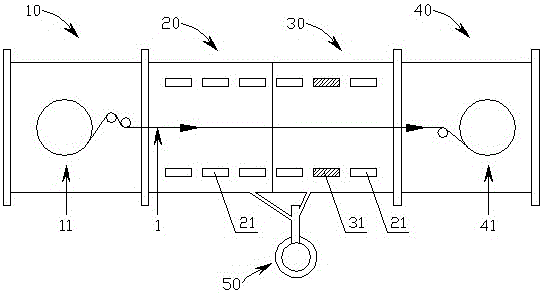

[0014] see you again figure 2 , figure 2 A schematic diagram of the structure and composition of a coating device for preparing a high-capacitance negative electrode foil is shown. The coating device of the present invention includes a vacuum unwinding chamber 10, a first vacuum coating chamber 20, a second vacuum coating chamber 30 and a vacuum winding chamber 40, The vacuum unwinding chamber 10 is provided with an unwinding mechanism 11, and the vacuum rewinding chamber 40 is provided with a winding mechanism 41. The aluminum foil 1 starts from the unwinding mechanism 11 and passes through the first vacuum coating chamber 20 and the second vacuum chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com