A body structure of AT power roll-core autotransformer

A technology of autotransformer and rolled iron core, which is applied in the direction of transformer/inductor core, transformer, fixed transformer, etc., to achieve the effect of strengthening insulation performance and heat dissipation performance, and reducing loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

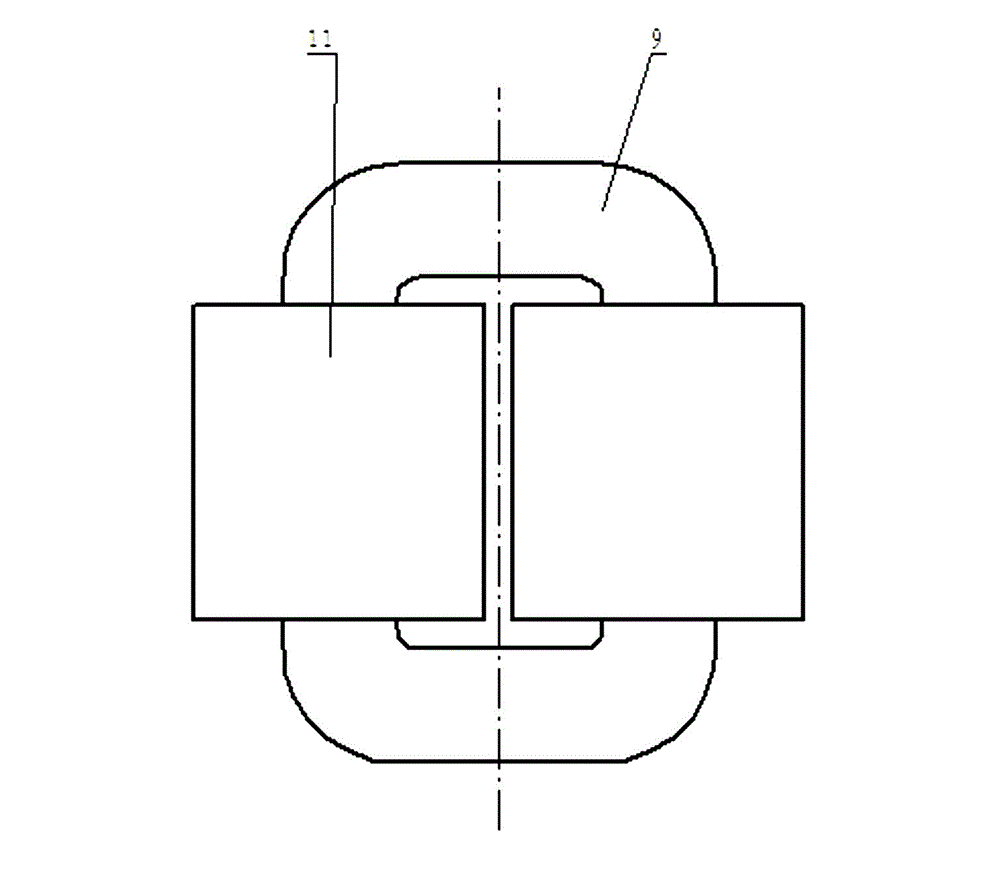

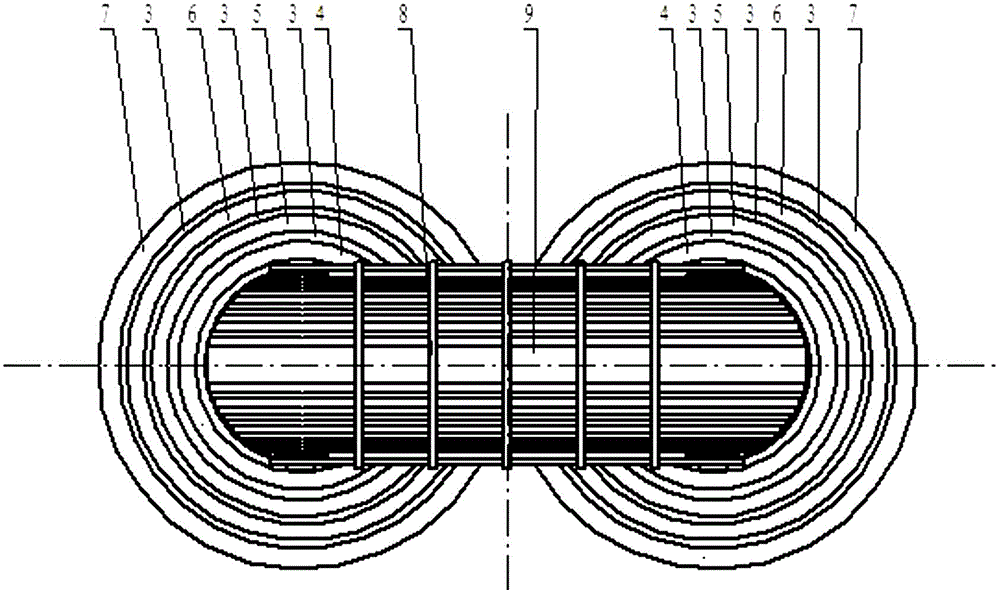

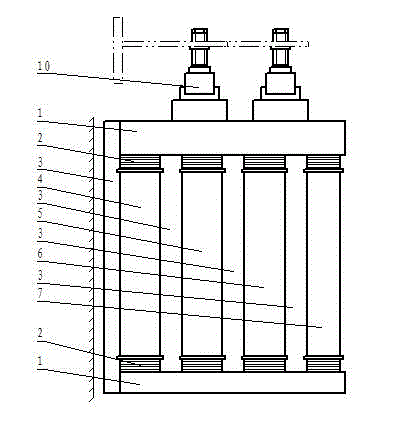

[0016] Such as figure 1 , 2 , 3, the present invention includes an iron core 9, a coil, an insulator 3 and a pressing device, the iron core 9 is a single-frame closed winding core structure, the vertical column of the iron core 9 is an iron core column, and the horizontal direction of the iron core 9 The column is an iron yoke, and a plurality of concentric coils are wound on one iron core column. The upper and lower ends of each coil are provided with insulating end rings 2, and the lower end of the lower insulating end ring 2 and the upper end of the upper insulating end ring 2 are provided with Iron yoke insulation board1. The iron core 9 is a closed structural iron core 9 with a circular or elliptical cross section rolled from a silicon steel sheet.

[0017] In order to strengthen the integrity of the iron core, the iron core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com