Fluid stirring paddle

A technology of fluid stirring and paddle arm, which is applied in the direction of mixers, dissolvers, and mixers with rotating stirring devices. It can solve the problems of affecting the mixing effect, clumping phenomenon, easy to generate negative pressure, etc., and achieve superior mixing effect and material circulation. Smooth, blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

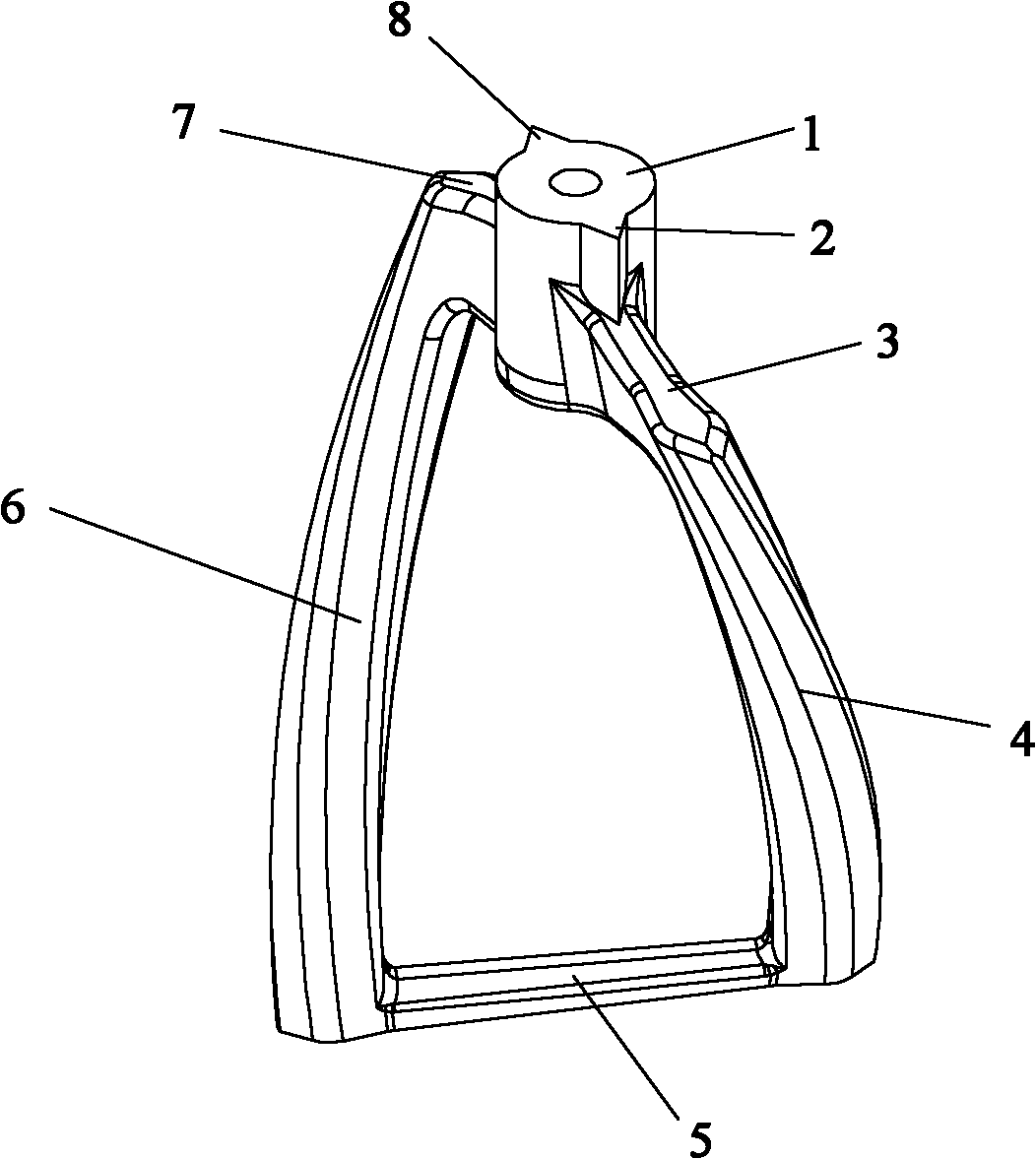

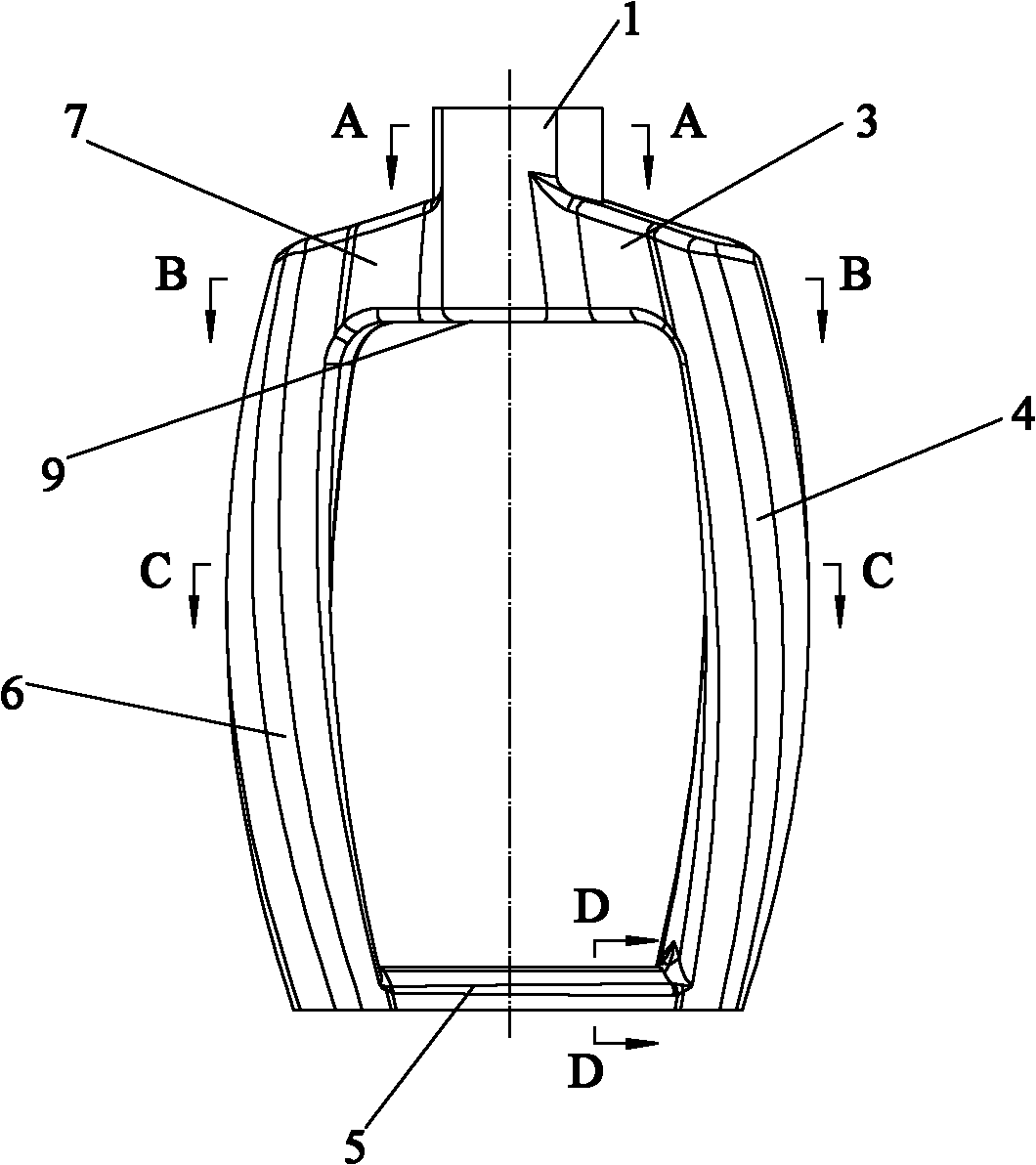

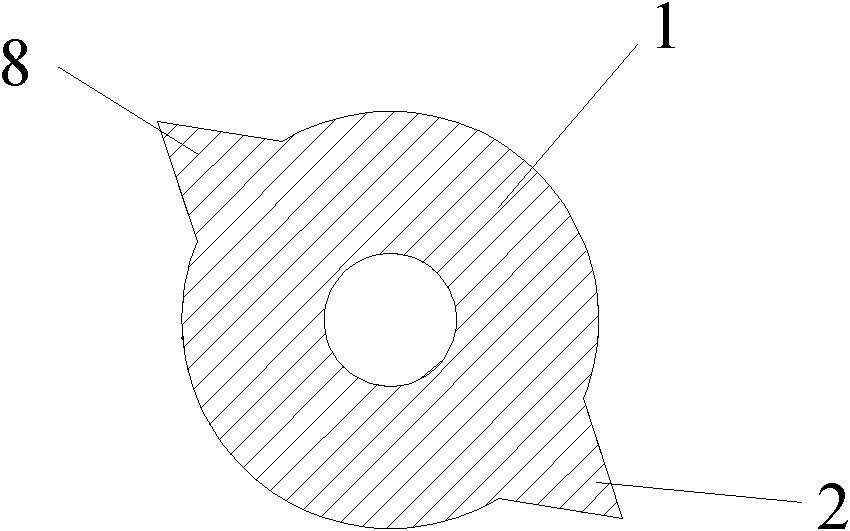

[0031] Figure 1 to Figure 8 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the fluid stirring paddle includes a shaft head 1 for connecting with a rotating shaft, two helical paddle arms 4, 6, and a paddle bottom 5 connecting the bottoms of the two paddle arms; the left and right sides of the shaft head 1 are Outward extension forms two paddle shoulders 3,7, as Figure 4 Shown; The undersides of two paddle shoulders 3,7 are connected to form a horizontal plane 9, as figure 2 As shown; the two ends of the two paddle shoulders 3,7 extend downwards to form the two paddle arms 4,6, as figure 1 and Figure 8 shown.

[0032] like figure 2 As shown, the two paddle shoulders 3, 7 extend outward from the middle of the shaft head 1, and the heights of the two paddle shoulders 3, 7 gradually decrease from inside to outside.

[0033] like figure 1 As shown, the left and right sides of the upper part of the shaft head 1 extend outwa...

Embodiment 2

[0040] The structure of this embodiment is the same as that of Embodiment 1 except for the following features: the left and right sides of the upper part of the shaft head extend outward to form four columns with gradually decreasing thicknesses, two of which are arranged on the left side of the upper part of the shaft head, and the other two One is located on the right side of the upper part of the shaft head; the bottom of the column is connected with the top of the oar shoulder.

Embodiment 3

[0042] This embodiment has the same structure as Embodiment 1 except for the following features: the length of the paddle arm in the radial direction of the shaft head is 10 mm, and the length in the direction of rotation is 5 mm; the length of the shortest side in the cross section of the paddle arm is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com