Novel technique of tungsten-molybdenum wire drawing and wire drawing device thereof

A new technology, wire drawing technology, applied in the direction of wire drawing die, etc., can solve the problems of affecting product quality, waste of parts, large visual temperature error, etc., and achieve the effect of improving product quality, intuitive and convenient operation, and accurate temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

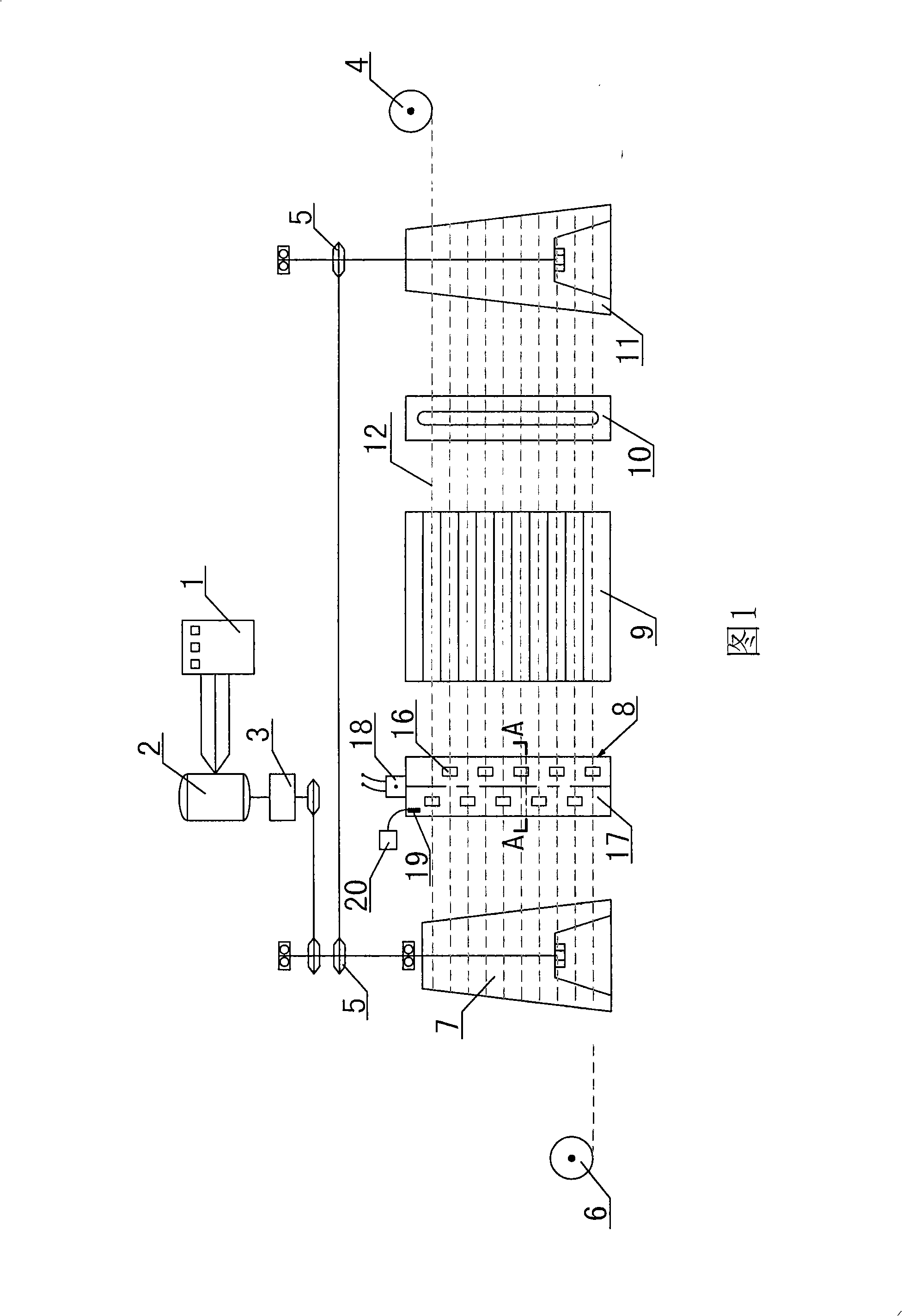

[0026] As shown in Figure 1: the tungsten-molybdenum wire drawing equipment includes a speed-adjusting frequency converter 1, a drive motor 2, a cycloidal needle reducer 3, a pay-off wheel 4, a transmission sprocket 5, a take-up wheel 6, a ceramic tower wheel 7, Automatic temperature control formwork 8, temperature-adjustable main heating furnace 9, graphite milk tank 10, rear drive tower wheel 11, described speed-regulating frequency converter 1 is connected with drive motor 2, between ceramic tower wheel 7 and drive motor 2 A cycloidal needle reducer 3 is arranged between them, and an automatic temperature control mold frame 8, an adjustable temperature main heating furnace 9, a graphite milk tank 10, tungsten wire or molybdenum The wire 12 is repeatedly wound between the ceramic tower wheel 7 and the rear driving tower wheel 11, and is set on the pay-off wheel 4 and the take-up wheel after passing through the automatic temperature control mold frame 8, the temperature-adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com