Integral type T-shaped outer cantilever roads and construction method thereof

A construction method and integral technology, applied to the integral T-shaped outer cantilever road and its construction field, can solve the problems of large number of masonry retaining wall projects, difficult construction, large engineering volume, etc., to avoid damage to the natural ecological environment, The effect of reducing the land occupation of the roadbed and strengthening the earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

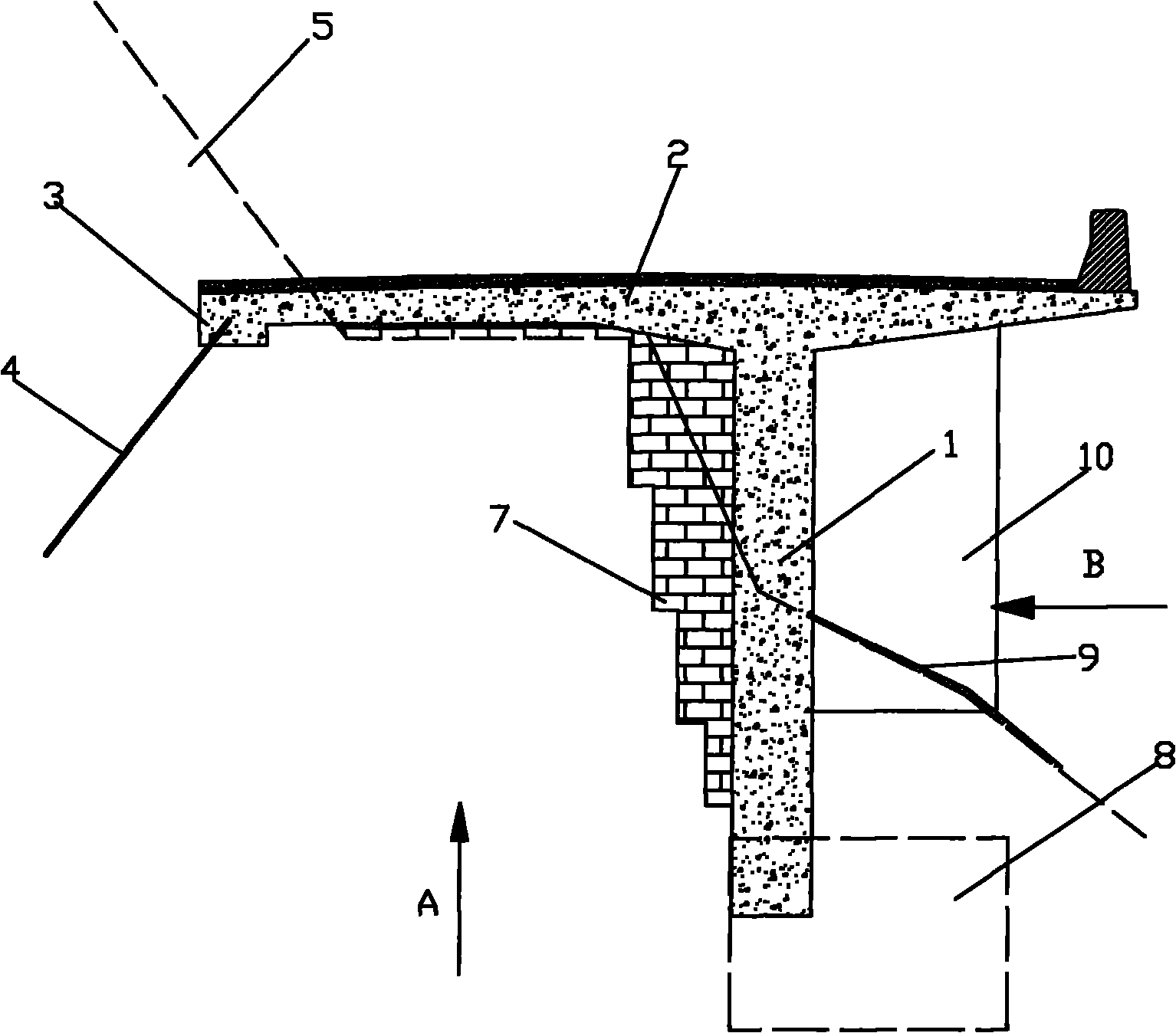

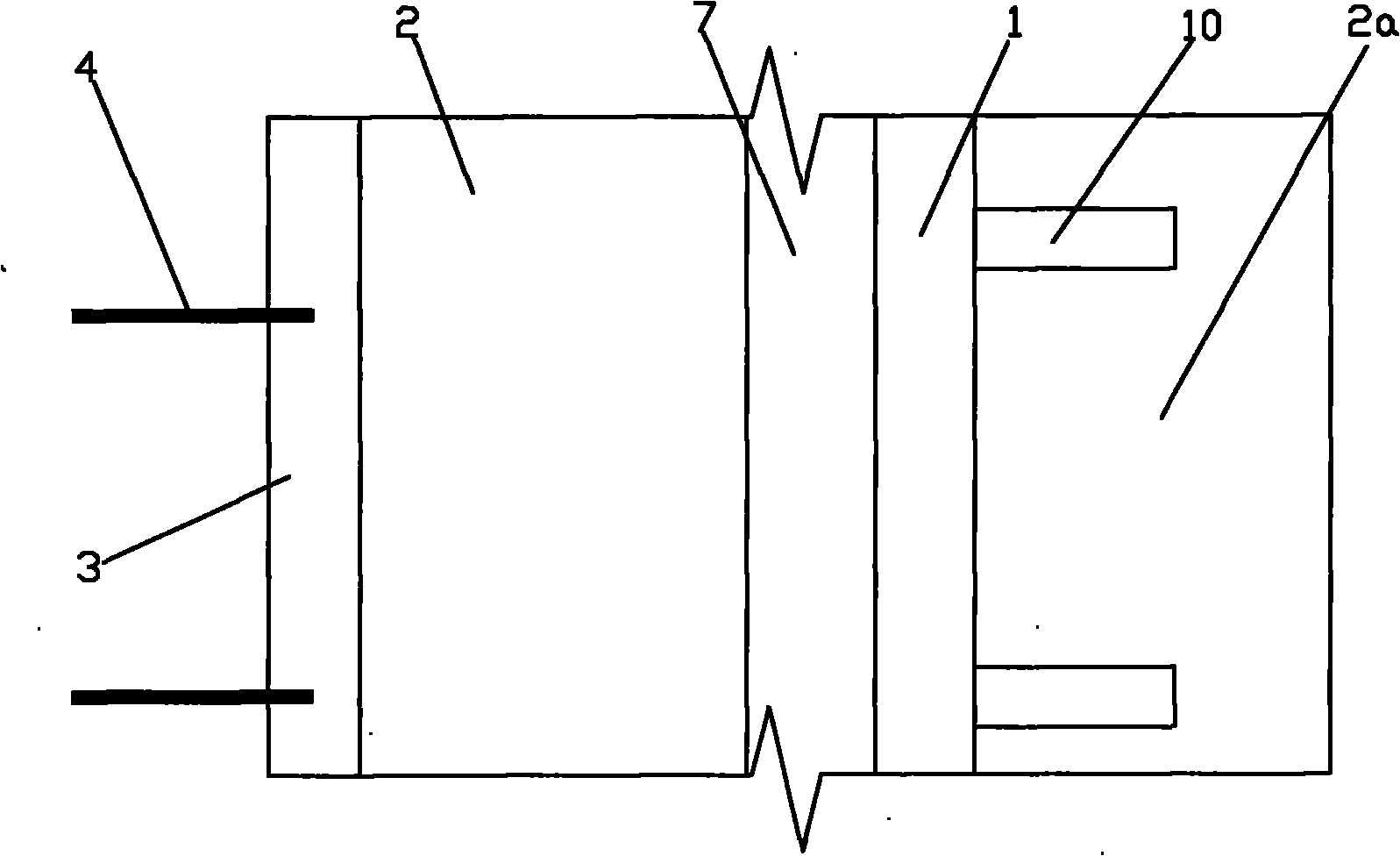

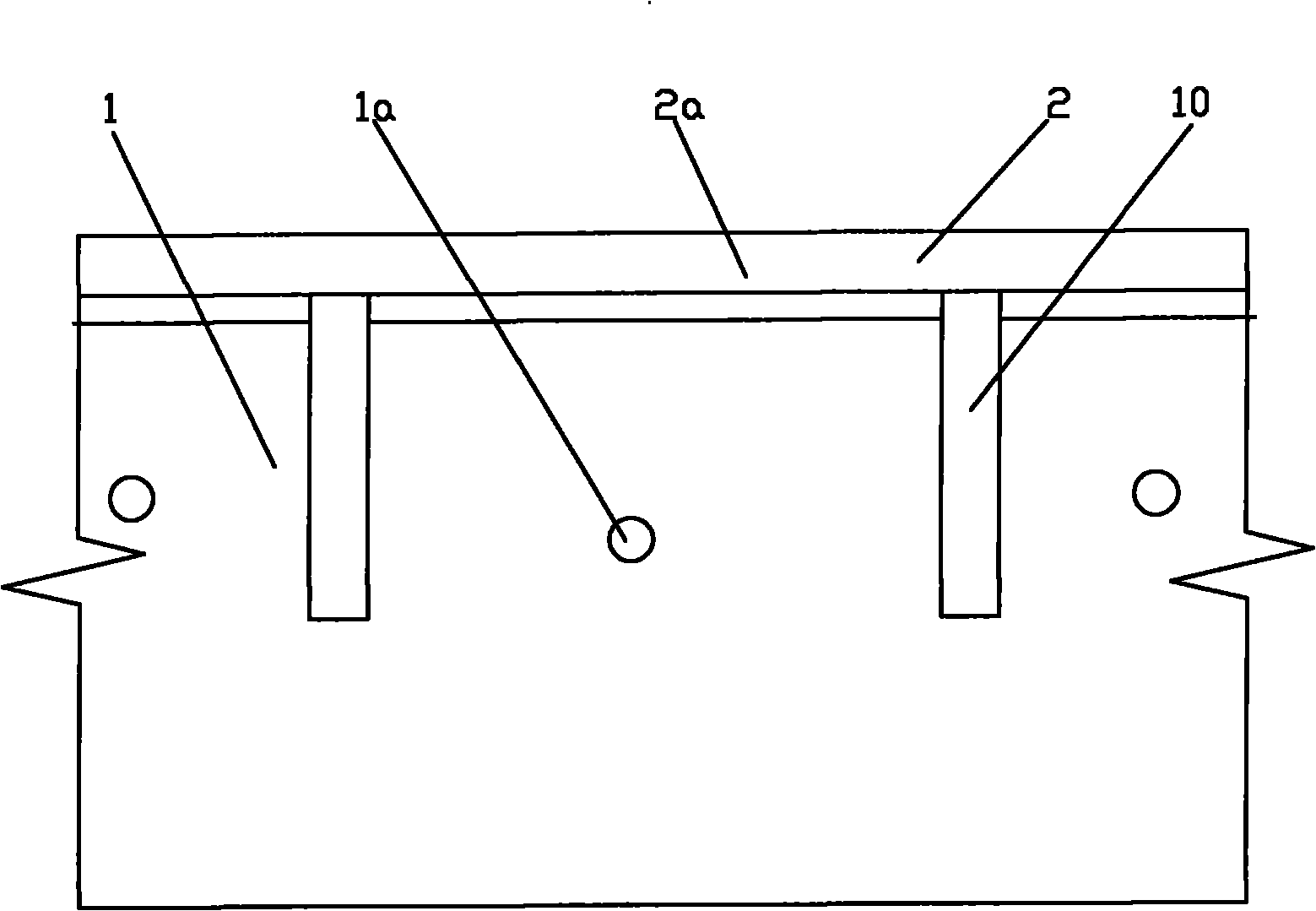

[0022] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along the A direction, image 3 for figure 1 View along the B direction, as shown in the figure: the integral T-shaped outer cantilever road of this embodiment includes a facade concrete retaining wall 1 and a concrete road panel 2, and the facade concrete retaining wall 1 is cast on the side slope 5 along the road. In the foundation groove of the direction, the concrete pavement panel 2 and the façade concrete retaining wall 1 are poured together to form a T-shaped road in cross section. Located on the inner subgrade 7 of the side slope, the inner edge of the concrete pavement 2 is integrally cast with the inner longitudinal beam 3 along the road direction.

[0023] In the present embodiment, the supporting transverse walls 10 arranged side by side along the road direction are cast integrally between the outer cantilever structure and the façade concrete retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com