Construction technology of ballast bed of bridge double-block ballastless track

A ballastless track and construction technology technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of less maintenance time, increased maintenance work, hindering the development of high-speed railway, etc., to improve the laying accuracy and construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

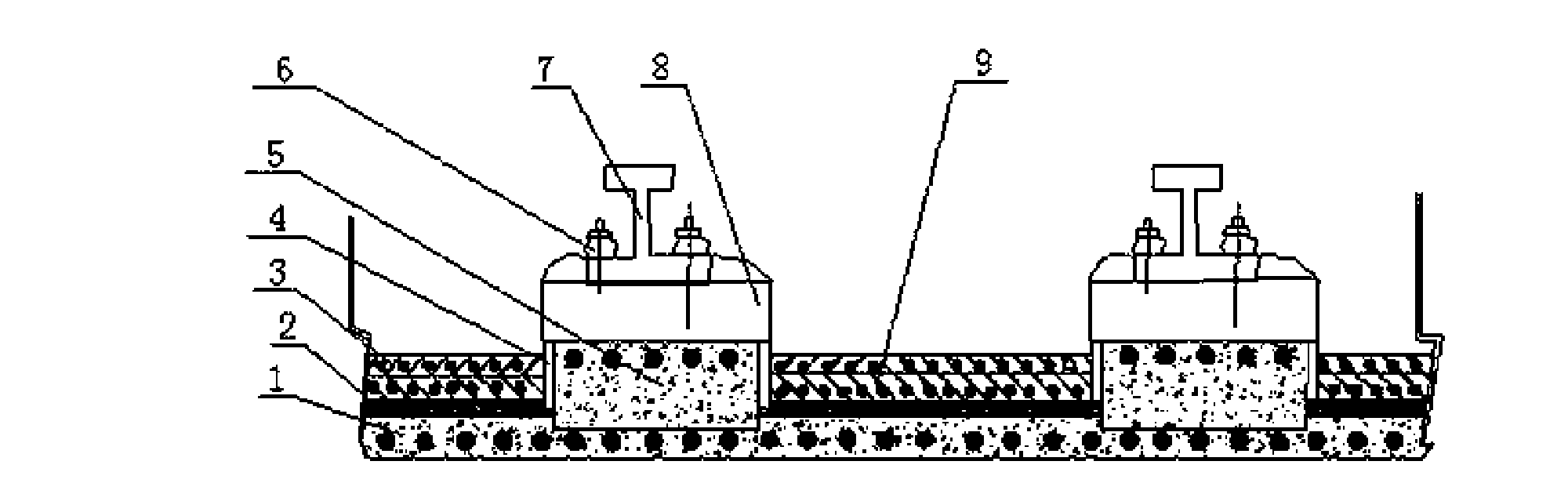

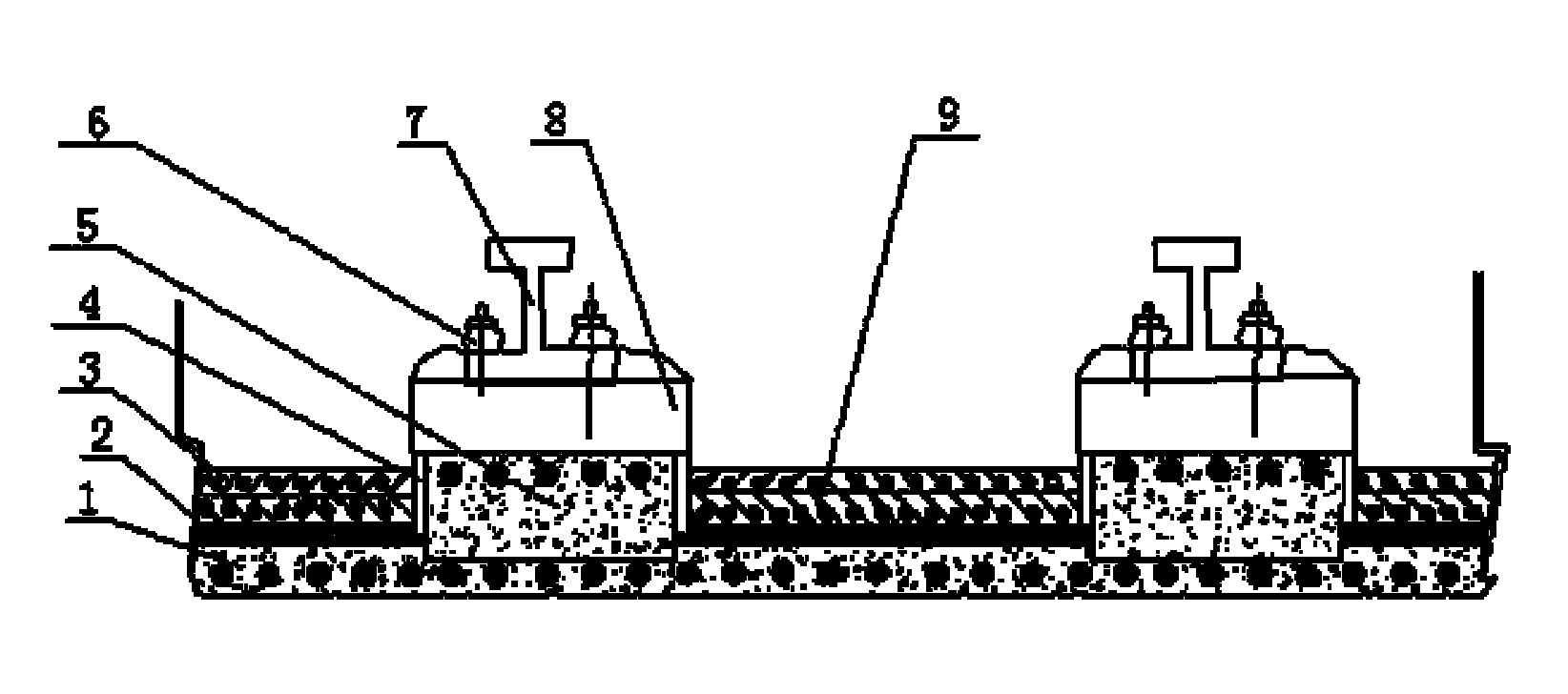

[0035] The present invention will be further described below in conjunction with accompanying drawing:

[0036] A construction technique for a double-block ballastless track bed on a bridge, comprising the following steps:

[0037] The first step is to ensure that the settlement of the bridge meets the construction requirements:

[0038] The second step is to clean the bridge deck:

[0039] Remove scum, dust and debris from the bridge deck of the bridge section;

[0040] The third step is to construct anti-collision walls, expansion joints and waterproof layers;

[0041] The fourth step is to lay the protective layer 1 and the embedded shear boss 5:

[0042] According to the stakeout points, use ink lines to pop up the left and right formwork edge lines, track centerlines and sleeper axes on the bridge deck of the bridge section; then, lay protective layer 1 steel bars along the track direction, and pre-bury shear resistance every 5 meters along the track direction Boss 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com