Bearing-lubricating device of turbojet engine

A turbojet engine and bearing lubrication technology, which is applied in the direction of engine lubrication, engine components, turbine/propulsion device lubrication, etc., can solve the problems of turbojet engine's overall volume increase and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

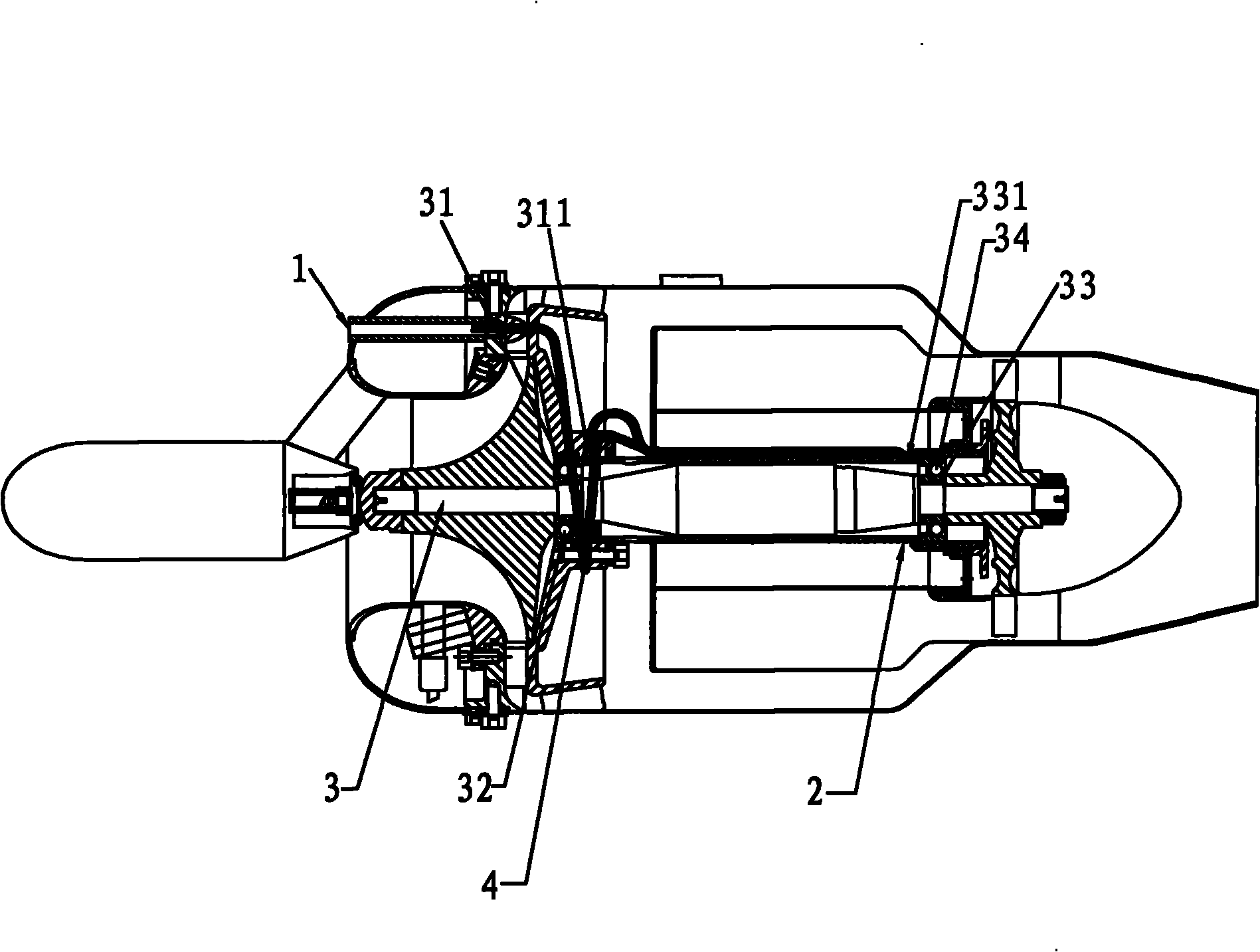

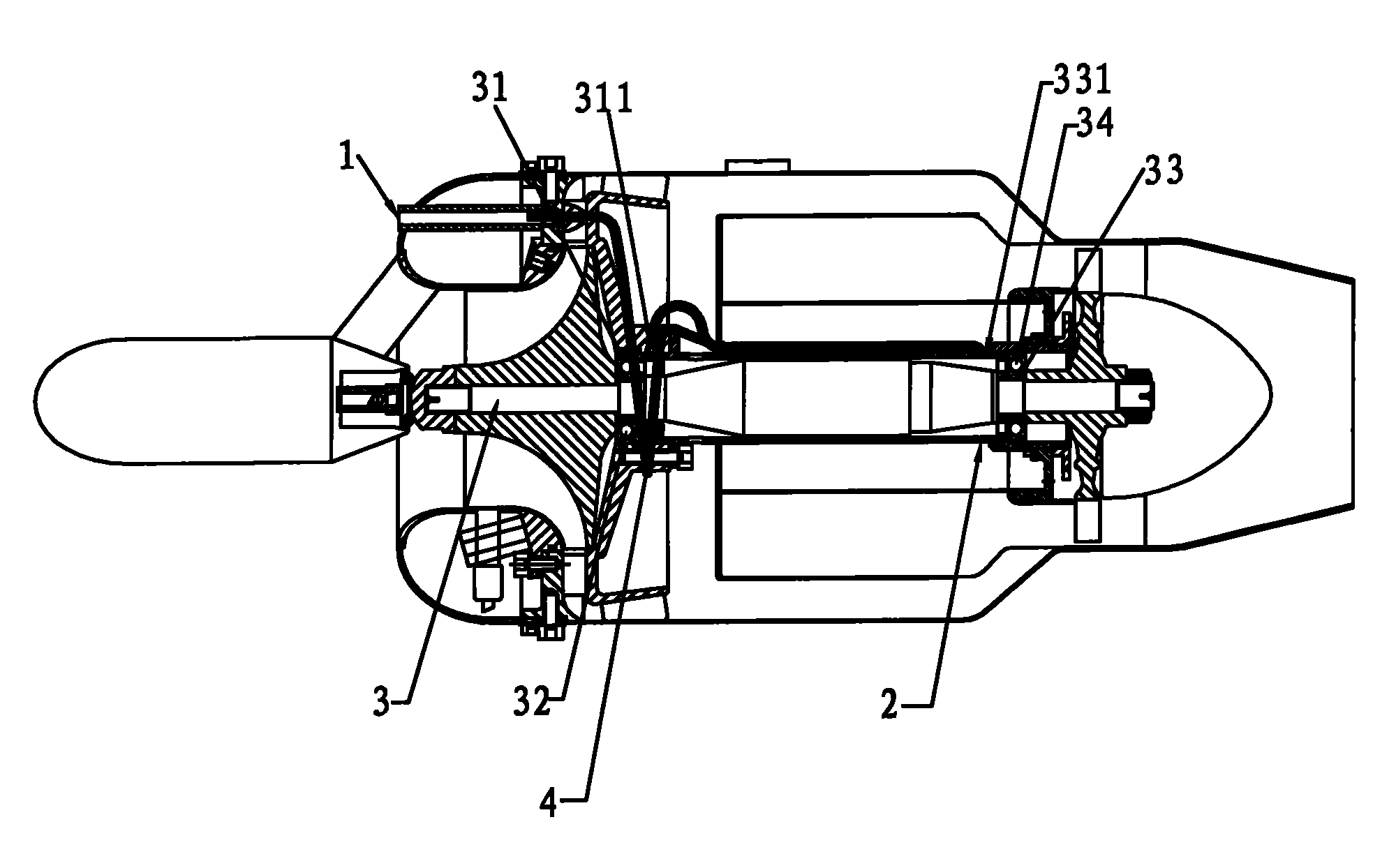

[0017] A kind of turbojet engine bearing lubricating device, as figure 1 Shown, it is to be provided with oil inlet 1 on the turbojet engine, and axle sleeve 2 is arranged in the turbojet engine, a main shaft 3 is set in the axle sleeve 2, the front end of main shaft 3 is provided with front bearing seat 31 and front The bearing 32 and the rear end of the main shaft 3 are provided with a rear bearing seat 33 and a rear bearing 34 . On the described axle sleeve 2, a slanted hole is provided at a position close to the rear bearing seat 33 to be the oil inlet 331 of the rear bearing, and in the turbojet engine, a slanted hole is also provided at the position close to the front bearing seat 31 to be the oil inlet of the front bearing. 311.

[0018] The present invention is provided with a lubricating oil pipe 4 in the oil inlet 1, adopts the principle of atomization lubrication, and can lubricate the rear bearing 34 and the front bearing 32 while the fuel is supplied for combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com