Digital ultrasonic flaw detection system and method

An ultrasonic flaw detection and digital technology, which is applied in the field of flaw detection system, can solve the problems of incapable of data fusion processing, inability to realize fusion processing of bottom wave, flaw wave or interface wave, and inability to monitor interface wave and flaw wave at the same time, so as to reduce high dependence on performance, reduce impact, and improve accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the new digital ultrasonic flaw detection processing method and system of the present invention will be described in detail below in conjunction with the accompanying drawings.

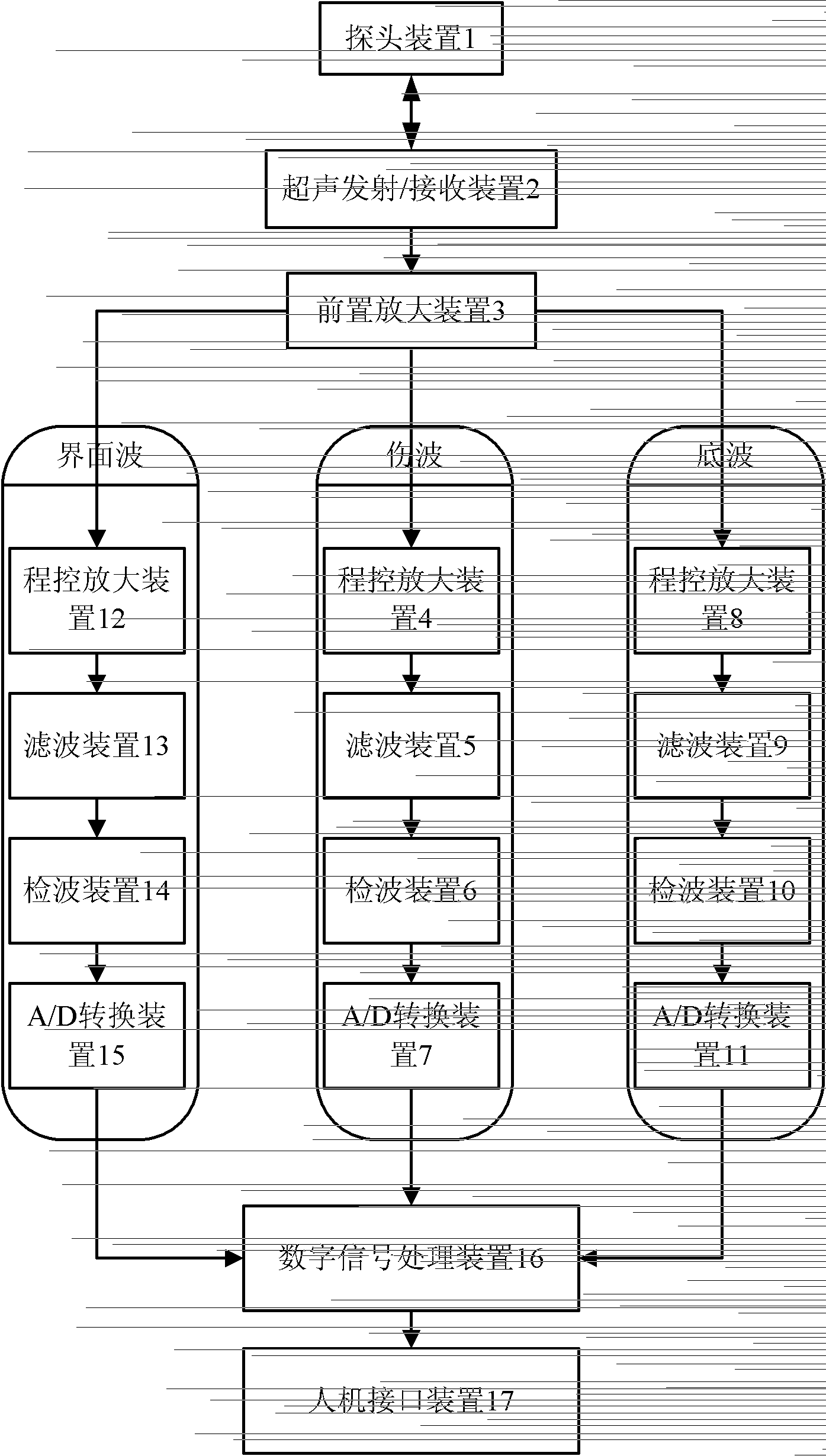

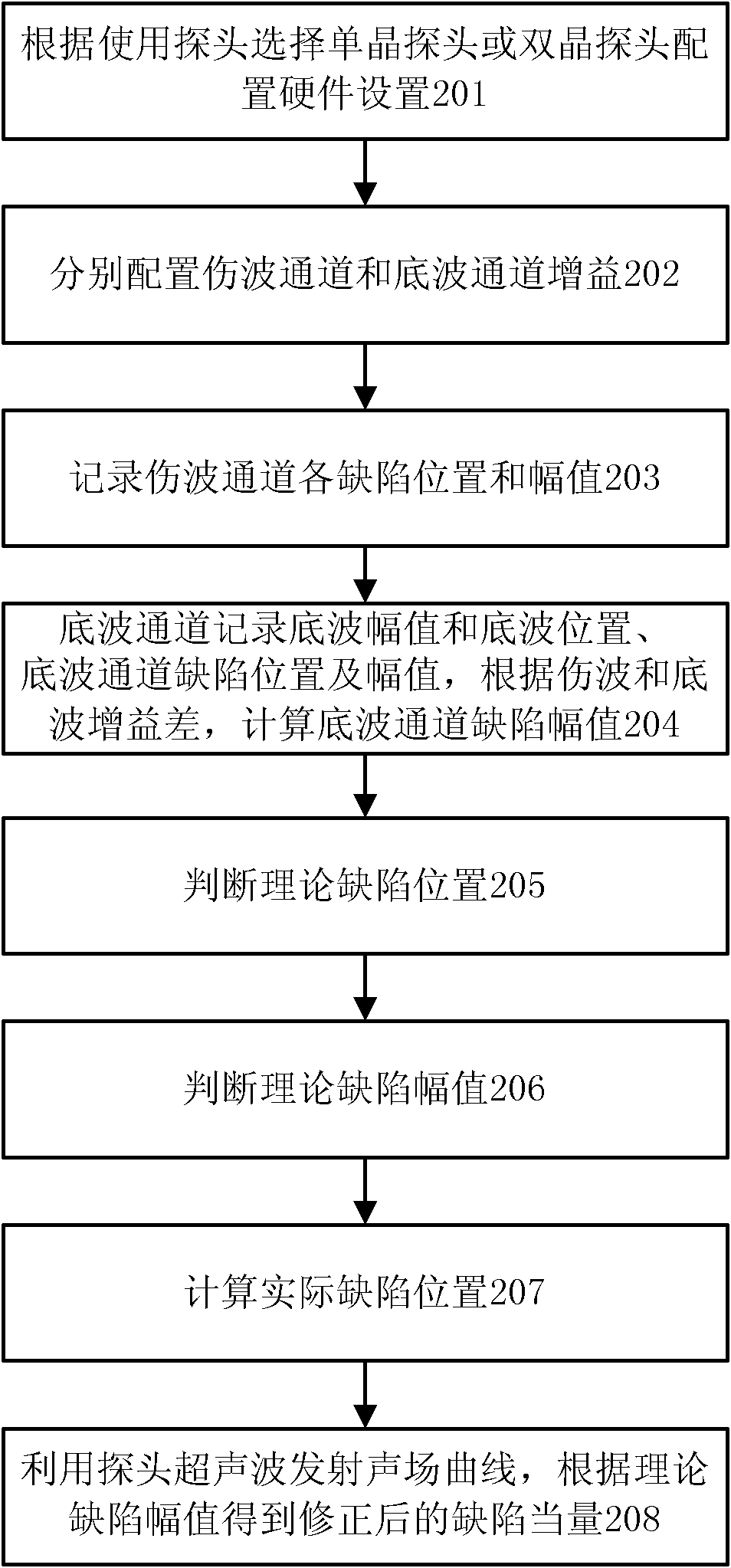

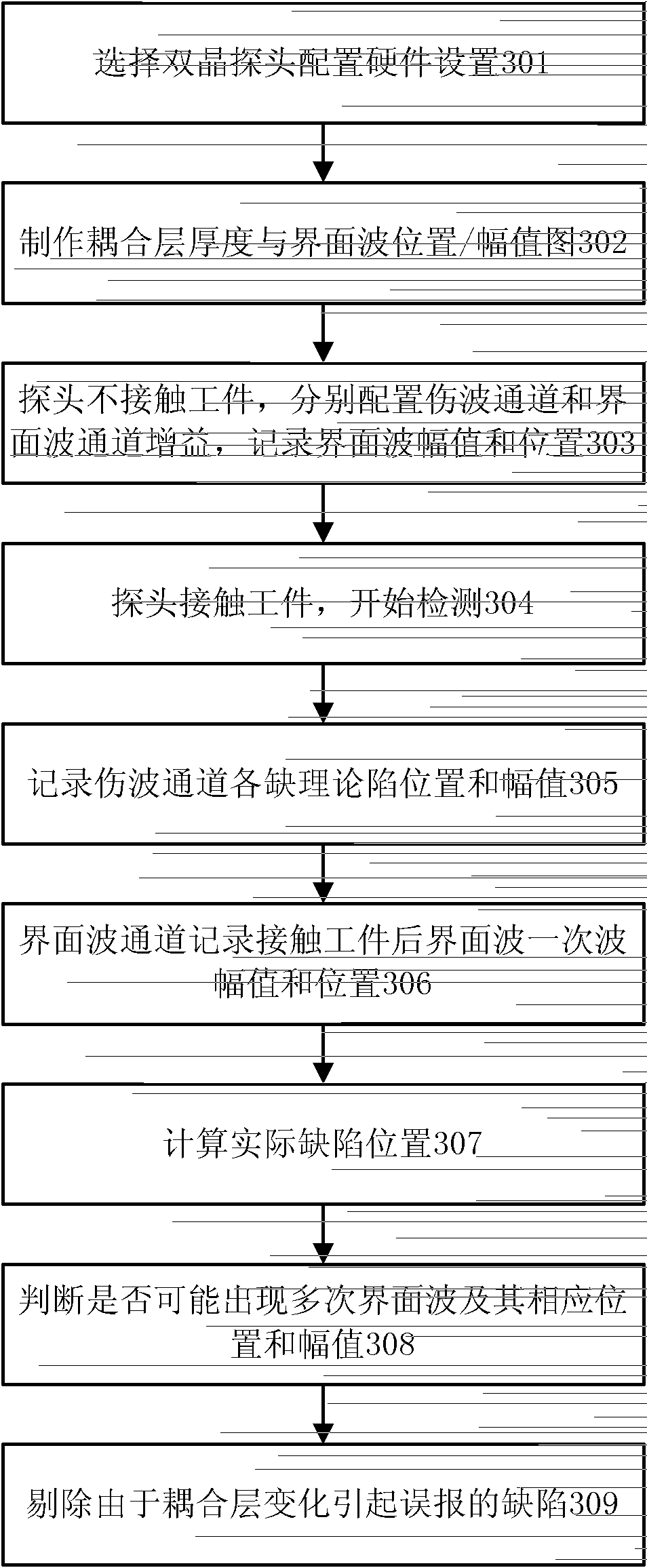

[0035] see figure 1 , The novel digital ultrasonic flaw detection system of the present invention includes at least 2 associated parallel physical channels, including two types of probes: single crystal probe and dual crystal probe.

[0036]The novel digital ultrasonic flaw detection system of the present invention includes a probe device 1, an ultrasonic transmitting / receiving device 2, and a preamplifier 3 connected in sequence, and a damage wave program-controlled amplification device 4, a damage wave filter device 5, and a damage wave filter device 5 connected in sequence to the preamplifier device 3. The wave detection device 6 and the damaged wave A / D conversion device 7 are sequentially connected to the bottom wave program-controlled amplifying device 8 of the pream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com