Conical soil-engaging component with abrasion-resistant geometric structural surface

A geometric structure and component technology, applied in the field of soil processing and soil measurement machinery design, to achieve the effect of improving wear resistance, prolonging service life, and reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

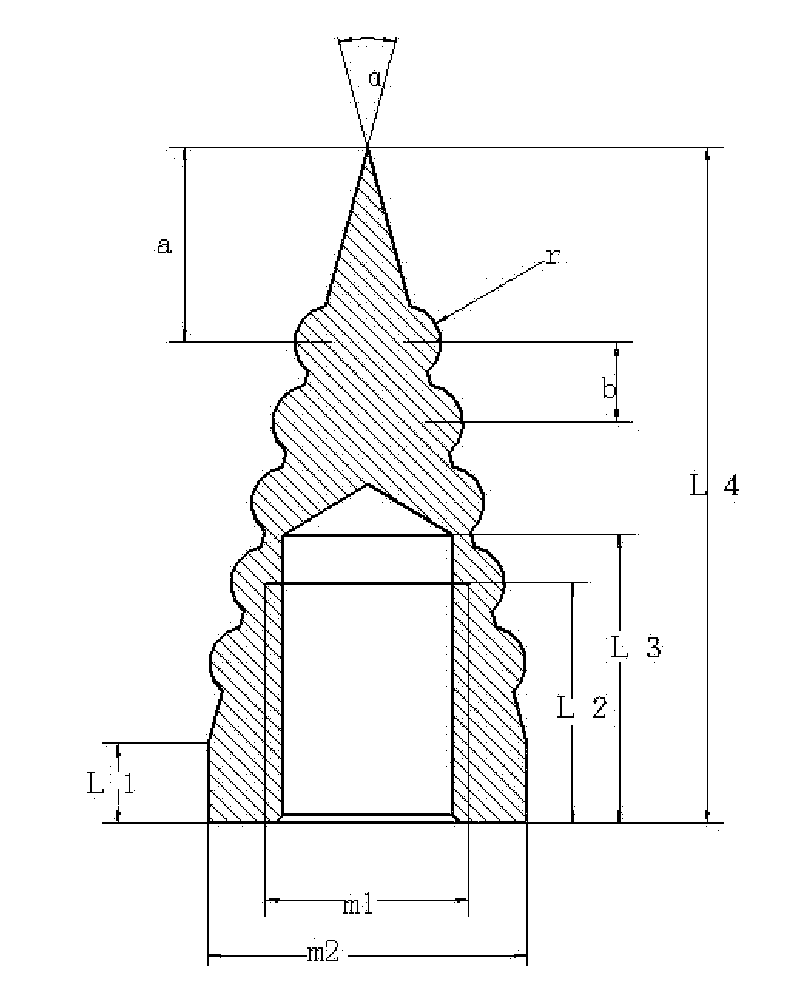

[0089] Embodiment 1, the surface of the cone head adopts a package structure.

[0090] Referring to Fig. 4(a), the distance a without structural features is 12.14 mm, the cone angle α is 30°, and the radius of the convex hull is r=1.5 mm. Convex hull interval b=5mm, number of convex hull rows n=5, base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head diameter m2=22mm.

[0091] Referring to Fig. 4(b), the distance a without structural features is 12.14 mm, the cone angle α is 30°, and the convex hull arc radius is 2 mm. Convex hull interval b=5mm, number of convex hull rows n=5, base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head diameter m2=22mm.

[0092] Referring to Fig. 4(c), the distance a without structural features is 12.14 mm, the cone angle α is 30°, and the convex hull arc radius is r=2.5 mm. Convex hull interval b=5...

Embodiment 2

[0093] Embodiment 2, the surface of the cone head adopts a pit-shaped structure.

[0094] Referring to Fig. 5(a), the distance of no structural features is a=8.95mm, the cone angle α=30°, and the radius of the pit arc is r=1.5mm. Pit spacing b=6mm, number of pit rows n=6 base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head diameter m2 =22mm.

[0095] Referring to Fig. 5(b), the distance a of no structural features is 8.95 mm, the cone angle α is 30°, and the radius of the pit arc is 2 mm. Dimple spacing b=6mm, number of dimple rows n=6, base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head diameter m2=22mm.

[0096] Referring to Fig. 5(c), the distance a of no structural features is 8.95 mm, the cone angle α is 30°, and the radius of the pit arc is 3 mm. Dimple spacing b=6mm, number of dimple rows n=6, base length L1=4mm, thre...

Embodiment 3

[0097] Embodiment 3, the surface of the cone head adopts a structure of annular concave rib type.

[0098] Referring to Figure 6(a), the distance a=14mm without structural features, the cone angle α=30°, the concave rib structure Arc radius r=1.5mm. Concave rib structure spacing b=3mm, number of concave rib rows n=10, base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head Diameter m2=22mm.

[0099] Referring to Fig. 6(b), the distance of no structural features is a=14mm, the cone angle α=30°, and the arc radius of the concave rib structure is r=2mm. Concave rib structure spacing b=3mm, number of concave rib rows n=10, base length L1=4mm, thread length L2=15mm, bolt length L3=18mm, cone head length L4=42.14mm, thread diameter m1=12mm, cone head Diameter m2=22mm.

[0100] Referring to Fig. 6(c), the distance of no structural features is a=14mm, the cone angle α=30°, and the arc radius of the concave ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com