Method for manufacturing holographic grating

A holographic grating and holographic recording technology, which is applied in the field of holographic gratings, can solve the problems of substrate aberration deterioration, difficulty and difficulty in manufacturing low-diffraction wave aberration holographic gratings, etc., to reduce manufacturing difficulty, reduce manufacturing difficulty and production cost, reduce Effect of processing difficulty and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

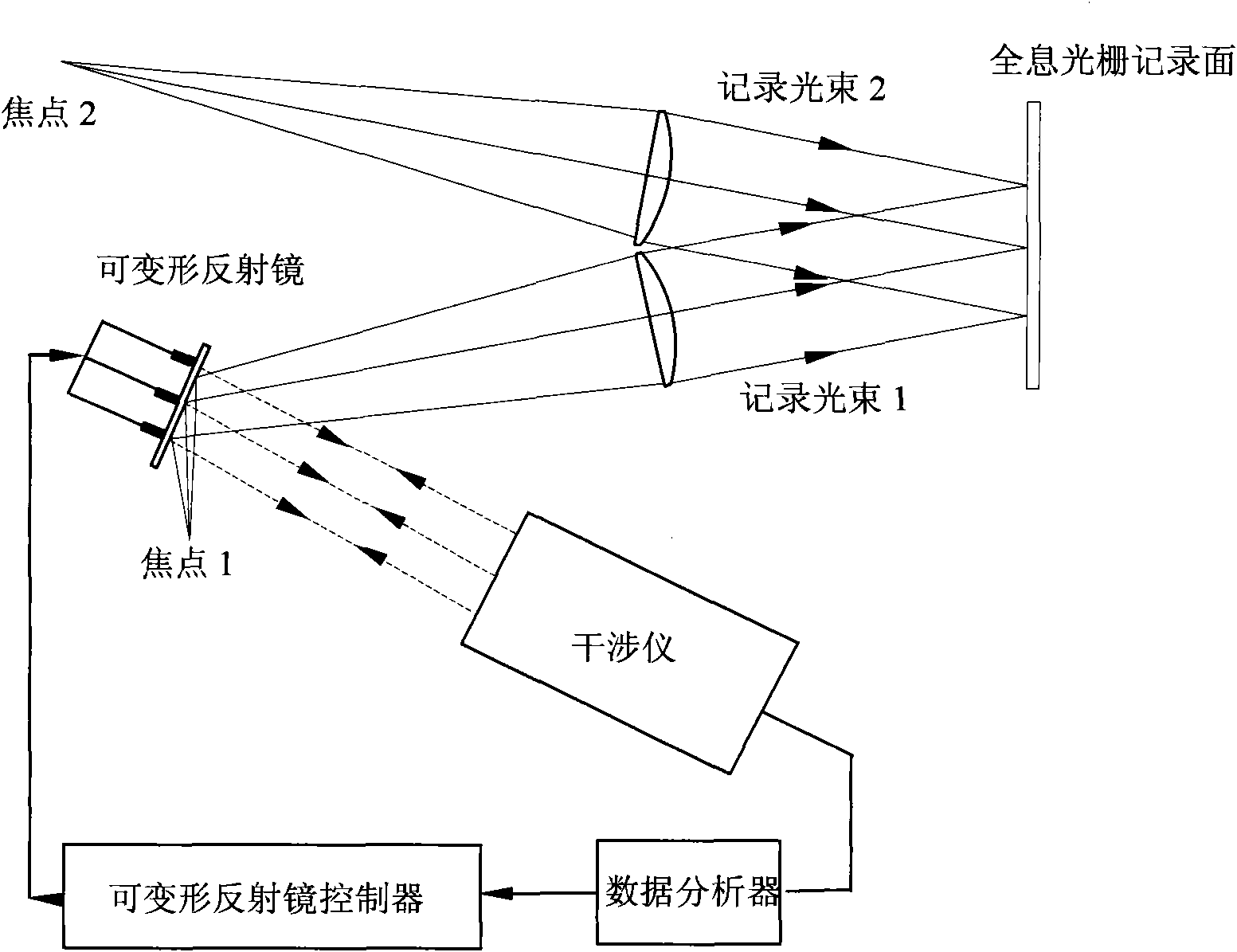

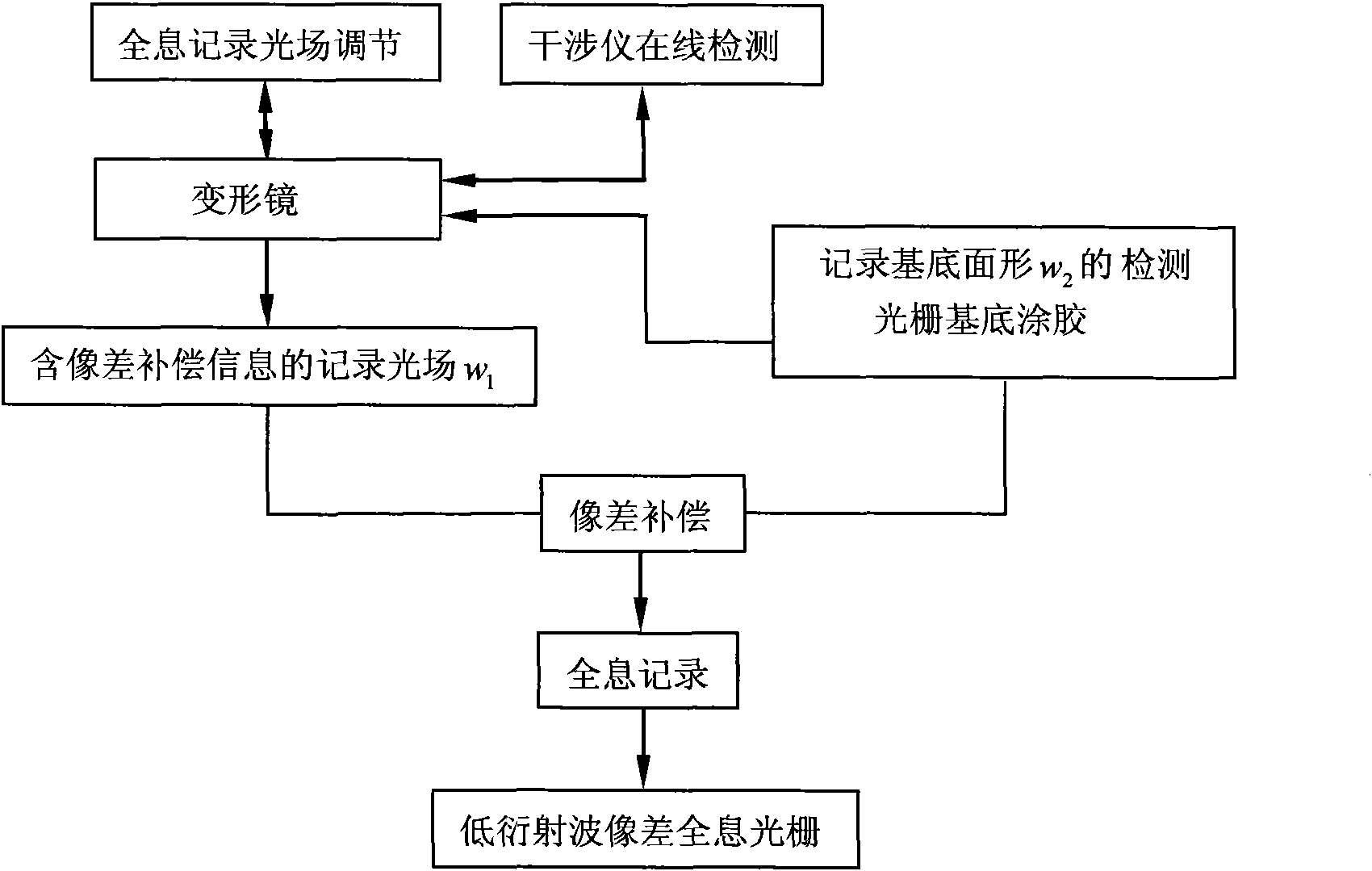

Method used

Image

Examples

Embodiment 1

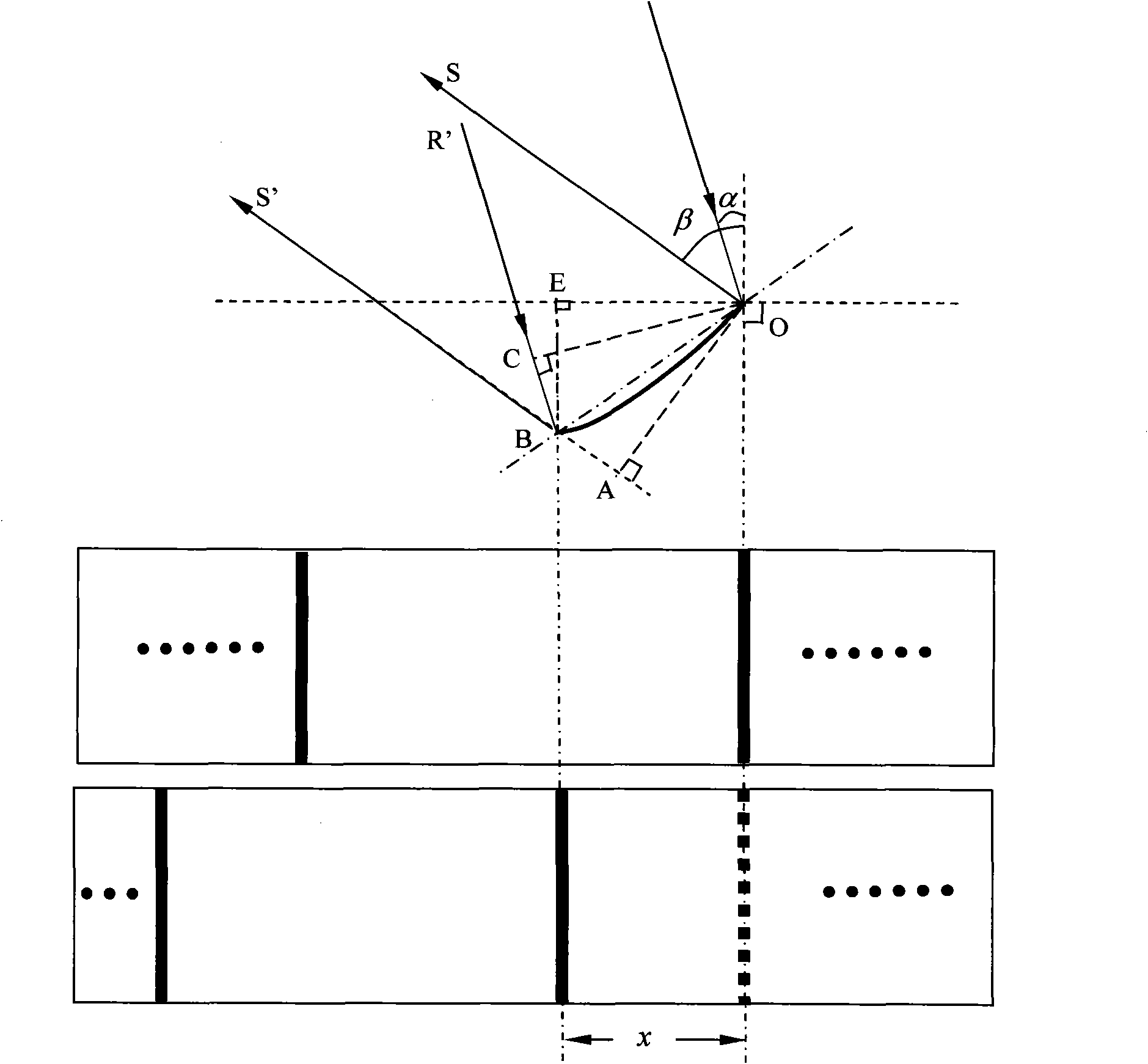

[0049] Comparison of the diffracted wave aberration of the large-scale grating made by the ordinary holographic recording method and the method of the present invention.

[0050]A one-dimensional holographic grating with a size of 200mm×400mm was fabricated by a common holographic recording method, and the spatial frequency of the grating was 1740lp / mm. The recording wavelength is 413.1nm, the two recording light beams are parallel light beams, the incident angles are both 21°, and the two recording light waves have no aberration. Assuming that the surface shape of the grating substrate coated with photoresist is 0.5 wavelength (the detection wavelength is 632.8nm), holographic exposure is performed on the substrate to make a holographic grating. When a beam of parallel light is incident on the holographic grating at the Littrow angle (that is, the incident angle is equal to the first-order diffraction angle of the grating, and the incident angle is 33.4°), the diffraction wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com