Helical lamp bepowdering device

A technology of powder coating and lamp tubes, which is applied in the manufacture of tubes/lamp screens and the application of luminescent coatings, etc. It can solve the problems of affecting the luminous efficiency of lamp tubes, thick spots of powder accumulation, and affecting the appearance of lamp tubes, so as to improve the maintenance of luminous flux Ratio, improve uniformity, increase the effect of luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

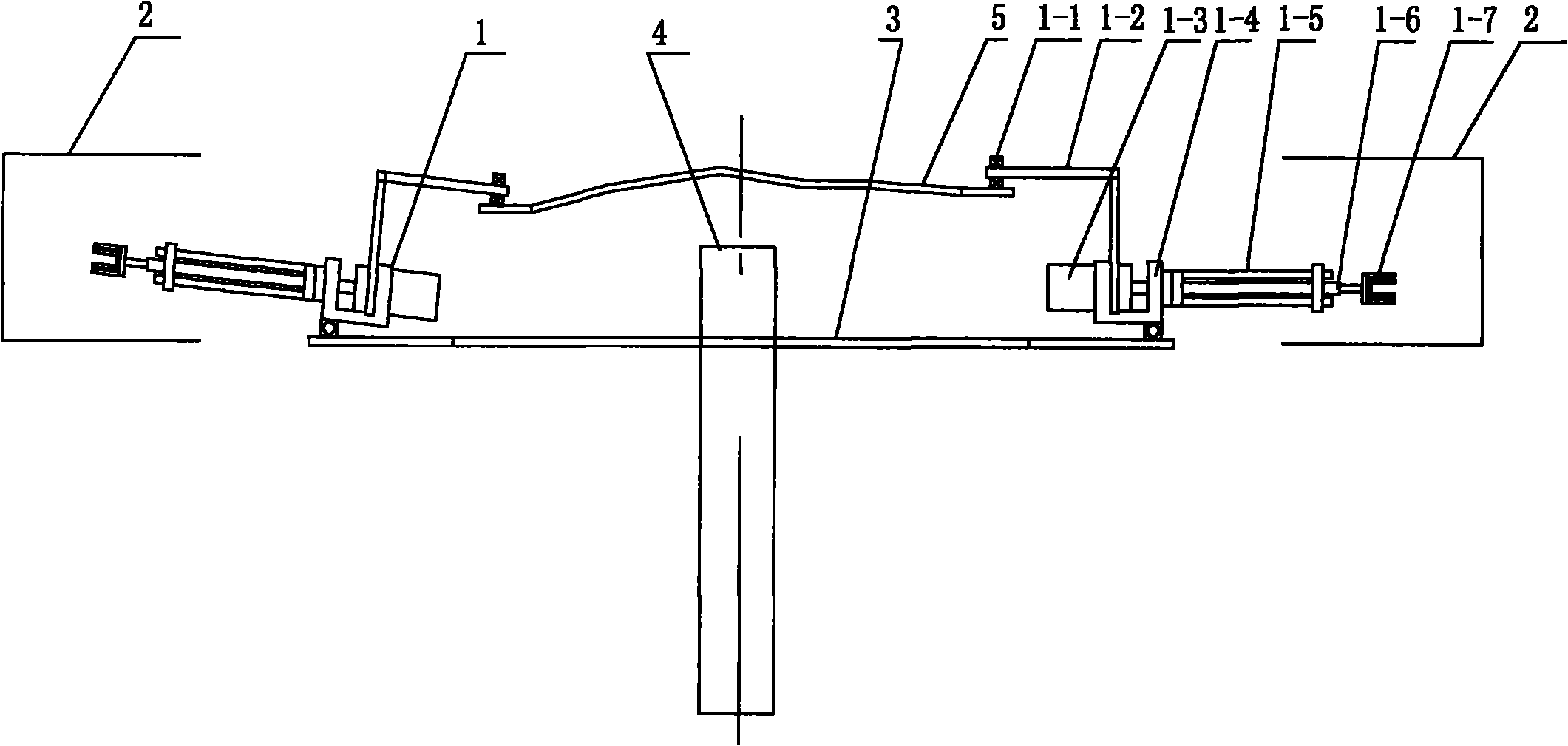

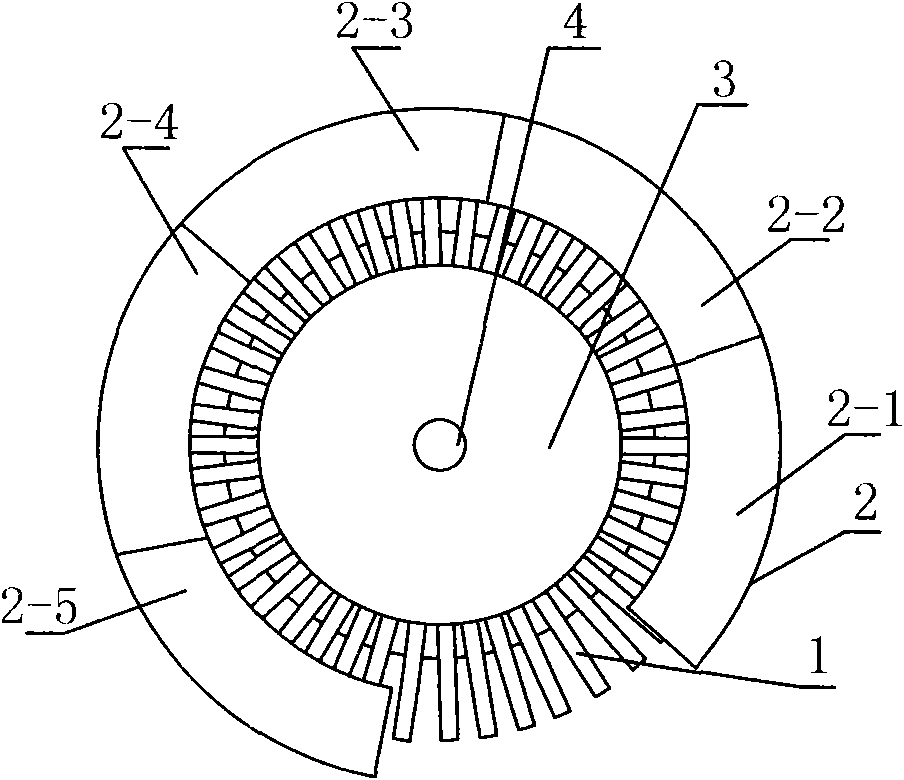

[0012] Embodiment 1: refer to figure 1 with 2 . Spiral lamp tube powder coating device, including rotating main shaft 4, motor and turntable 3, rotating main shaft 4 is connected with the center of turntable 3, and the motor drives turntable 3 to rotate around the rotating main shaft 4, and said spiral lamp tube powder coating device also includes a ring Guide plate 5, powder coating tool 1 and baking oven 2, several powder coating tools 1 are distributed on the turntable 3, the annular guide plate 5 is fixed above the turntable 3, and the powder coating tool 1 is composed of a rotating motor 1-3, a motor base 1- 4. The support arm 1-2 and the capillary gripper 1-7 are composed, the rotating motor 1-3 is connected with the motor base 1-4, the front end of the motor base 1-4 is hinged with the turntable 3, and the rear end is connected with the support arm 1-2 , the upper end of the support arm 1-2 is connected with the annular guide plate 5, the capillary gripper 1-7 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com