Paper inserting machine of stator core wire embedding slots

A stator core and embedded wire slot technology, which is applied to the shape/style/structure of winding insulation, laying solid insulation, etc., can solve the problems of high labor intensity and low efficiency for operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

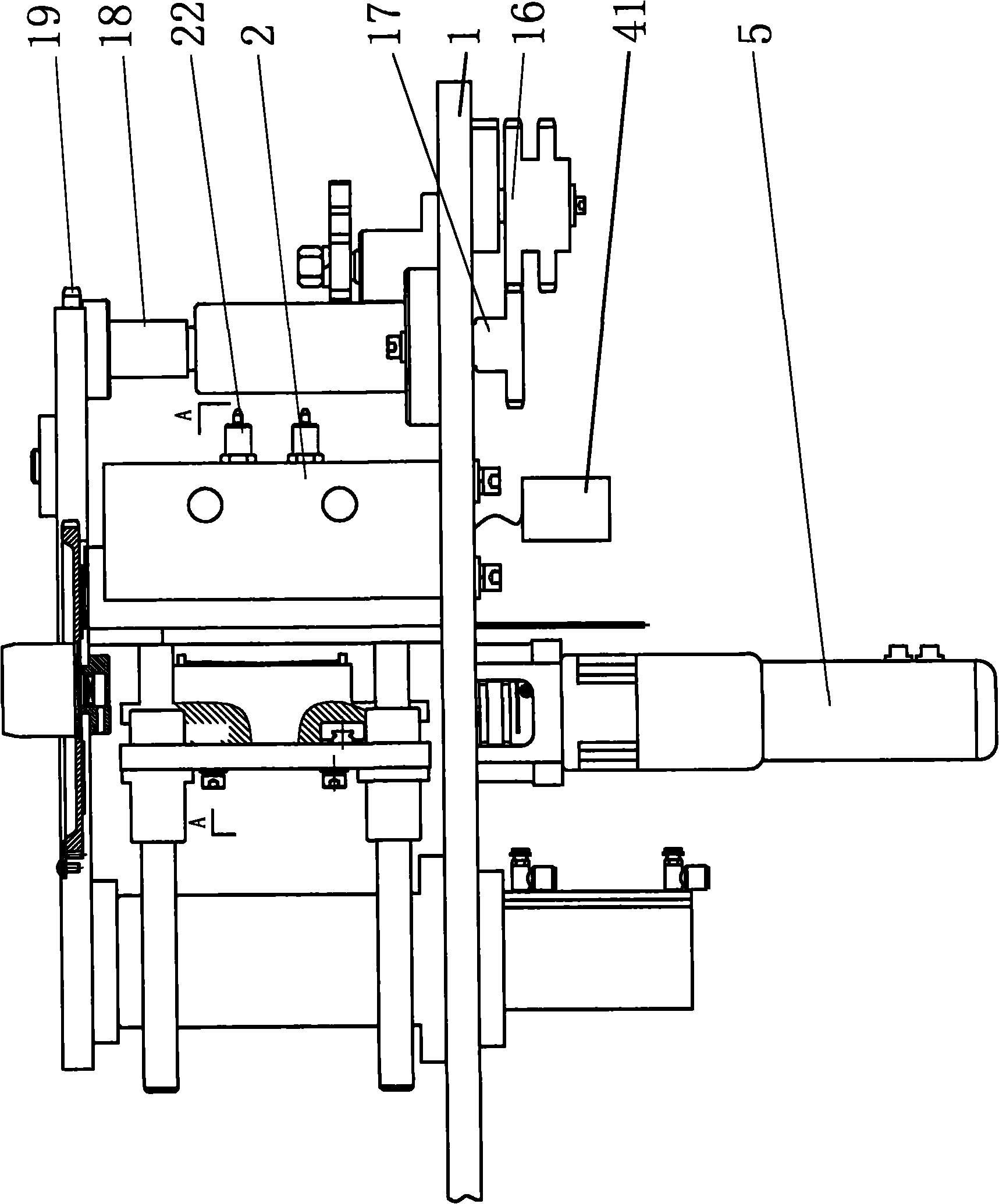

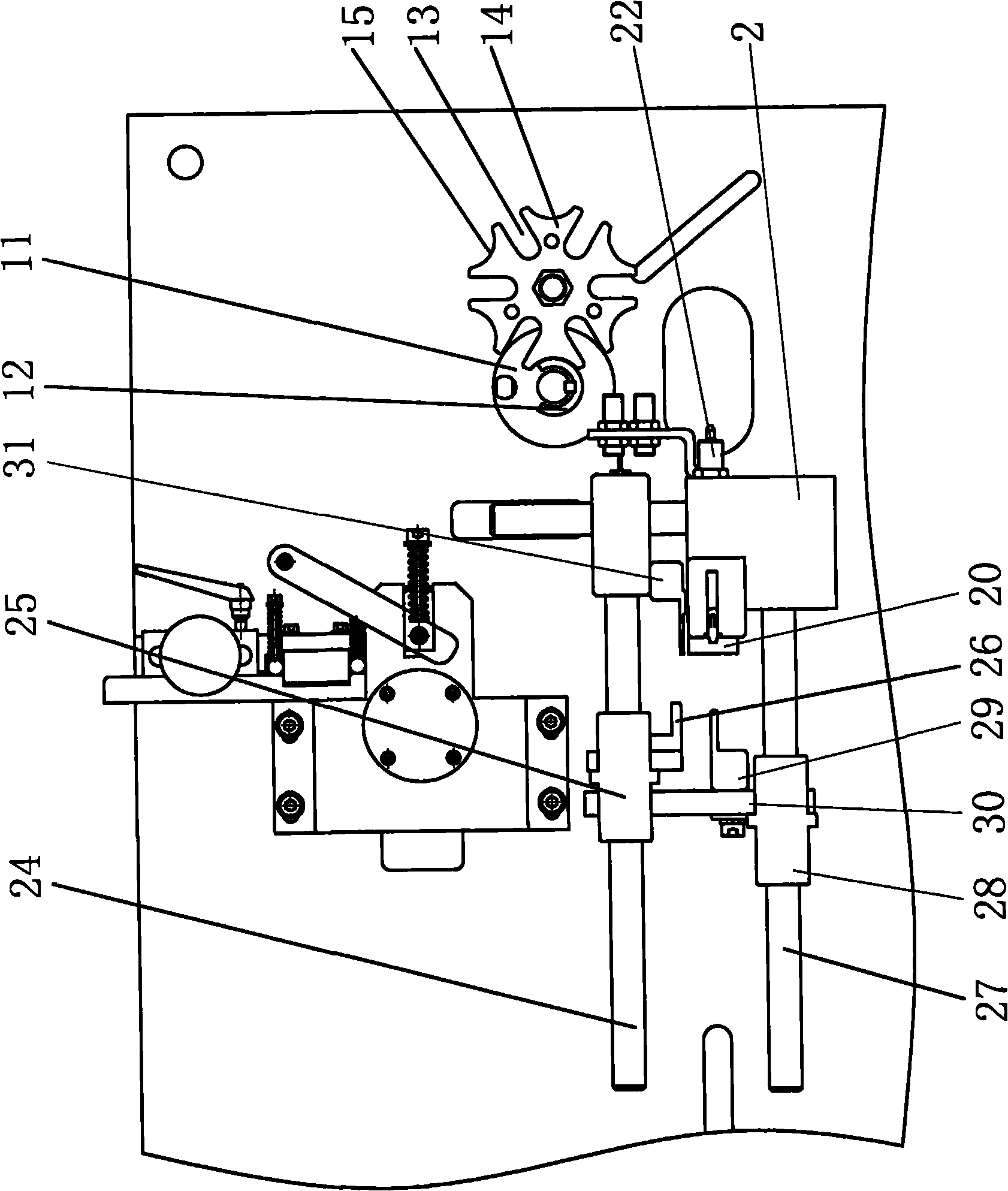

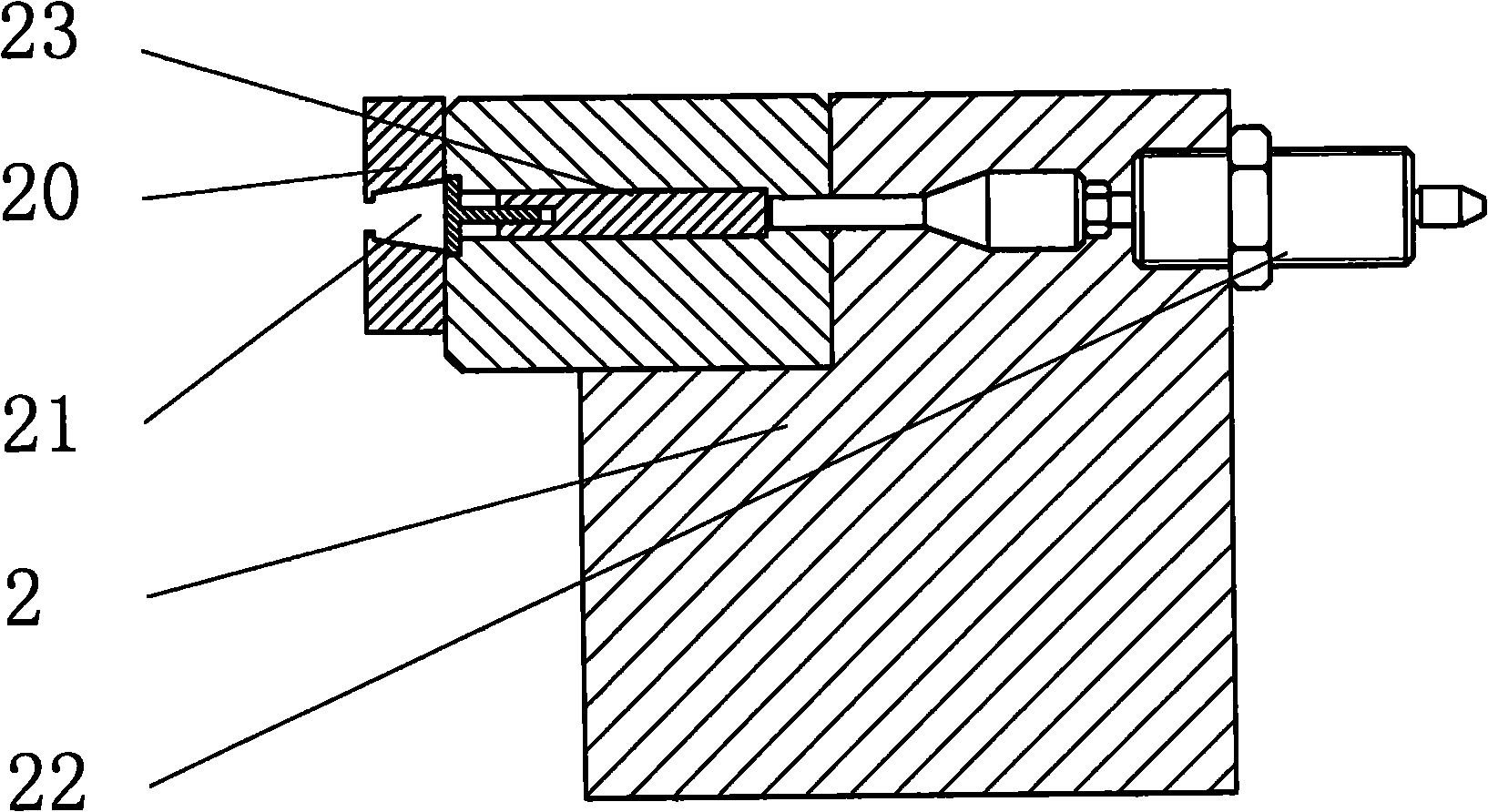

[0016] refer to Figure 1 to Figure 5 , the paper insertion machine of the stator core embedding groove of the present invention comprises a workbench, a mold device for assembling the stator core arranged on the workbench, a paper feeding mechanism arranged on the workbench, and a workbench The top-up mechanism that pushes the formed insulating paper into the slot of the stator core, it also includes the indexing mechanism set on the workbench, which can form an insulating paper forming device suitable for various slot types, and a controller for controlling the work of the indexing mechanism, the insulating paper forming device, the paper feeding mechanism and the lifting mechanism, the output end of the indexing mechanism meshes with the mold gear on the mold device, and the insulating paper forming device is located on the side of the paper feeding mechanism, The insulating paper forming unit is located under the mold gear of the mold unit.

[0017] refer to figure 1 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com