Pulsed-liquid phase discharge system based on multiplex IGCT parallel connection

A pulse discharge, liquid phase technology, applied in the field of high power pulse, liquid phase pulse discharge system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

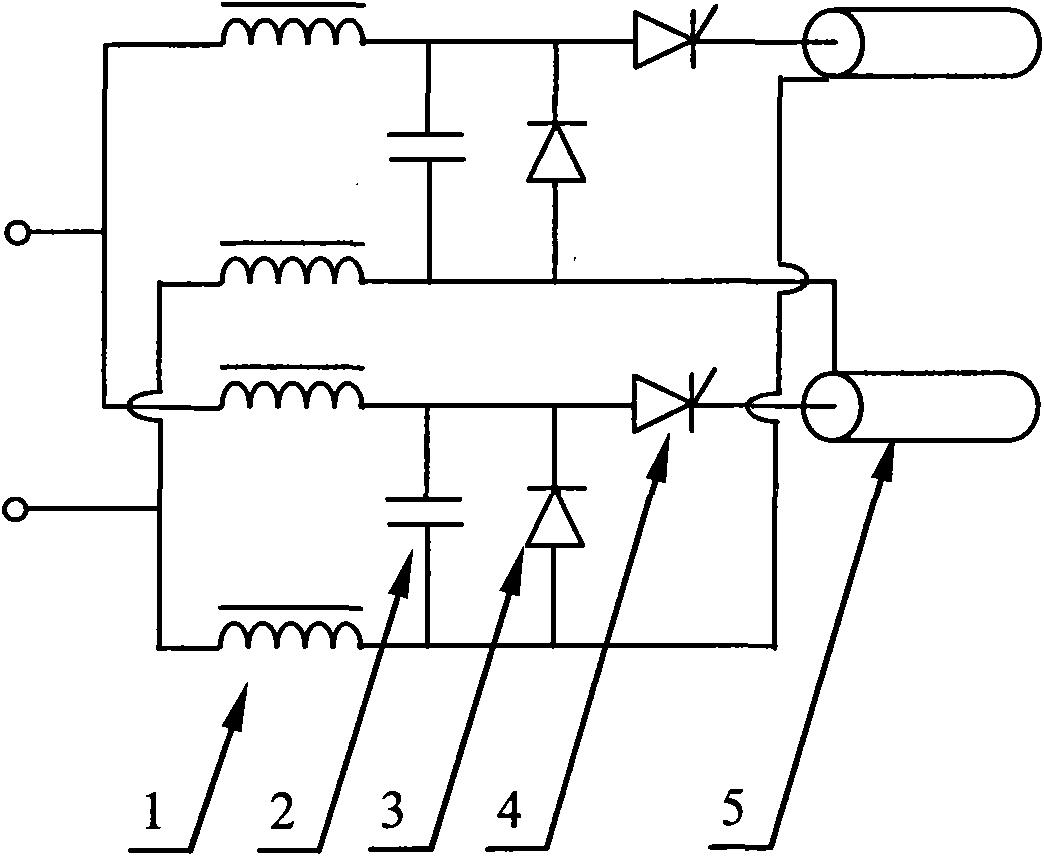

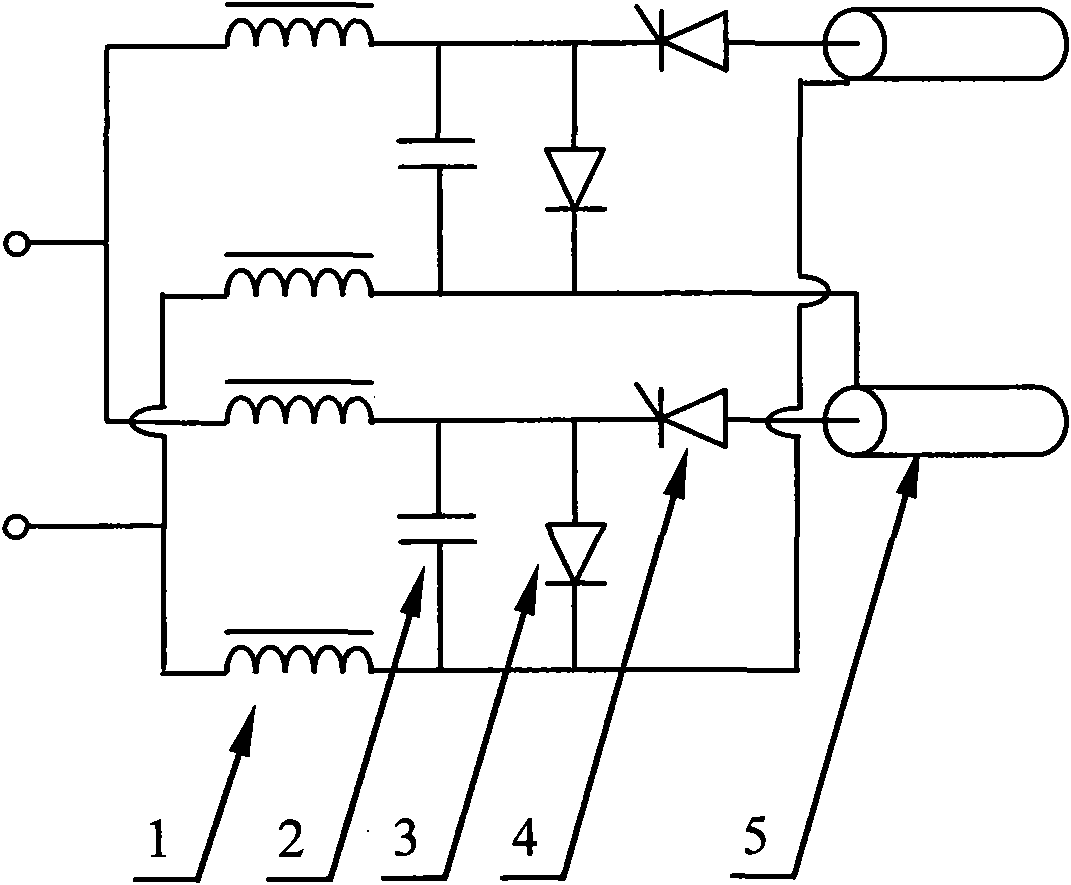

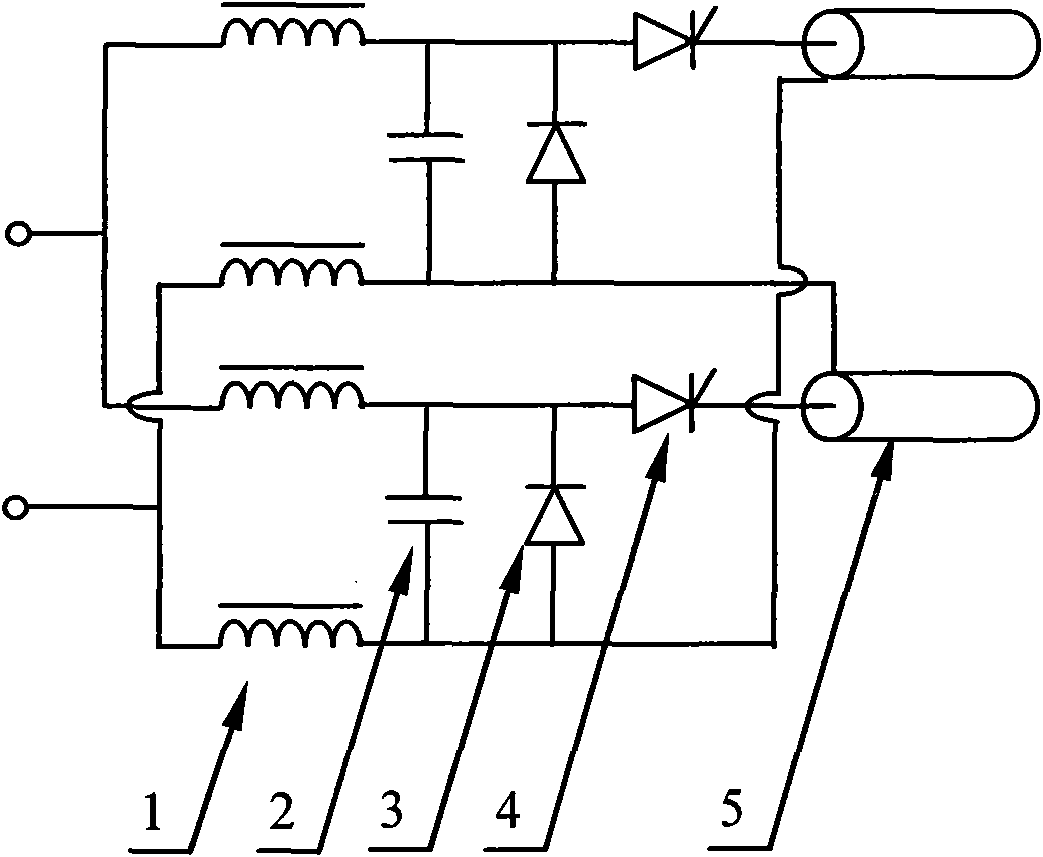

[0016] figure 1 It is the circuit diagram of the positive high voltage pulse output for the present invention. As shown in the figure, a liquid-phase pulse discharge system with multiple IGCTs connected in parallel can be composed of two or more discharge circuits connected in parallel. The components of each path, including the current limiting inductor 1, the energy storage capacitor 2, the freewheeling diode 3, the IGCT switch 4 and the pulse transmission line 5, are connected in sequence. There are two current-limiting inductors 1 for each channel, which are respectively connected in series with the high-voltage input end and the low-voltage input end of the energy storage capacitor 2 to play the role of current limiting. They can be air-core inductors or include magnetic cores. The energy storage capacitor 2 can be composed of one or more low-inductance solid-state pulse energy storage capacitors connected in series and parallel. The freewheeling diode 3 is connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com