Capacitive automatic reversing device and method for operating automatic reversing device

An automatic reversing, capacitive technology, applied in the direction of the power control mechanism, the control mechanism of the wing leaf, the electronic switch, etc., can solve the problems that the electrical connection cannot be guaranteed, measurement error, contact reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

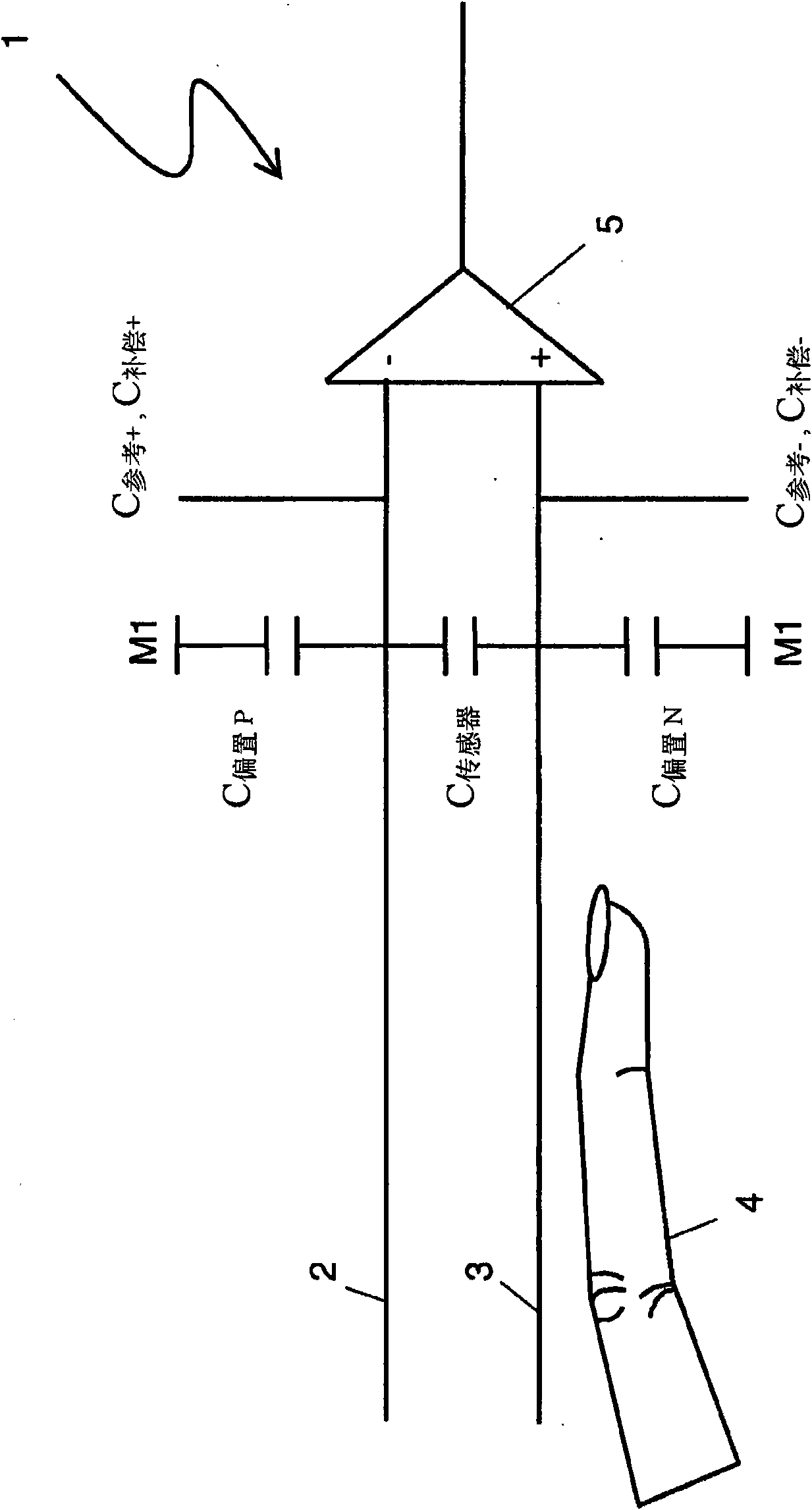

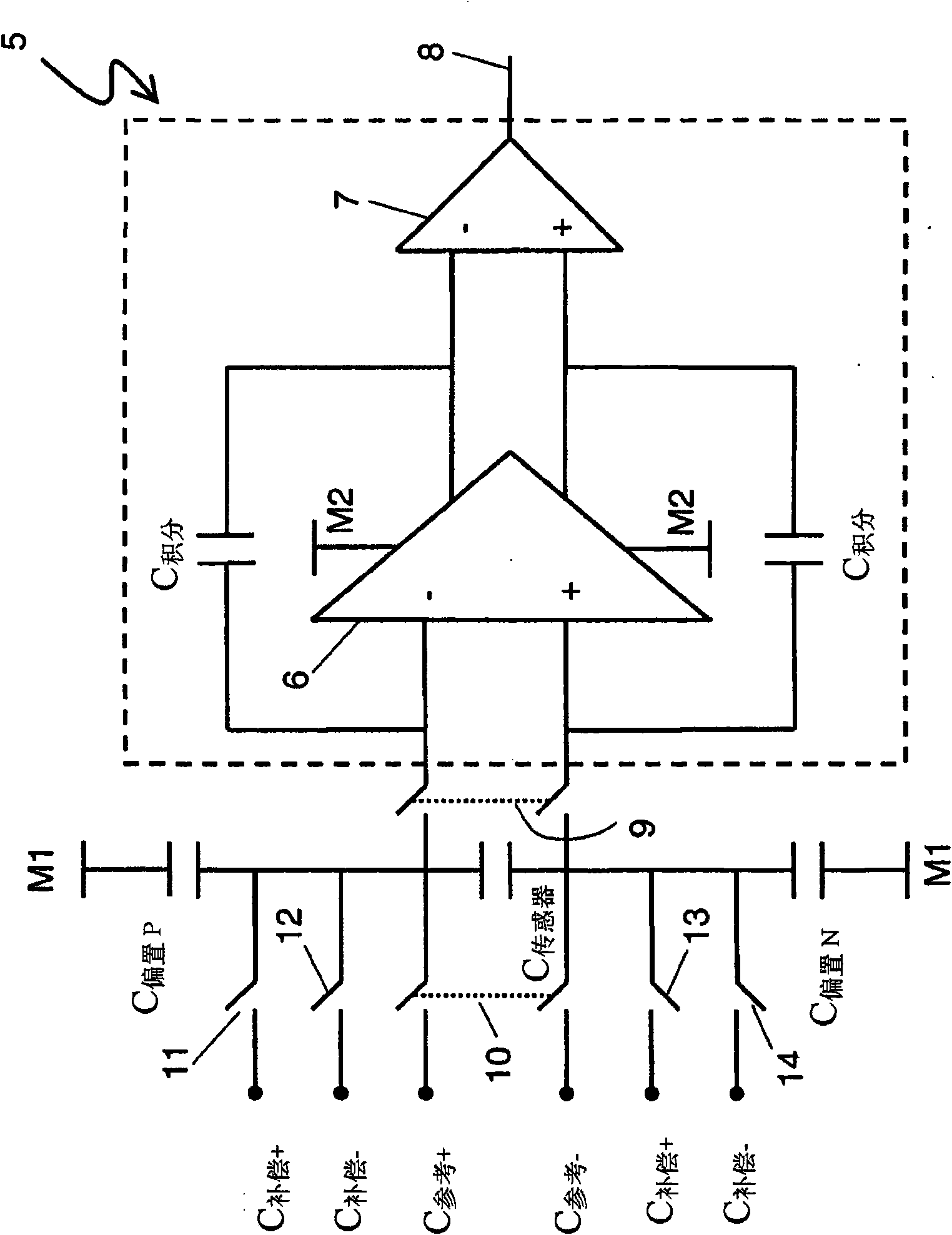

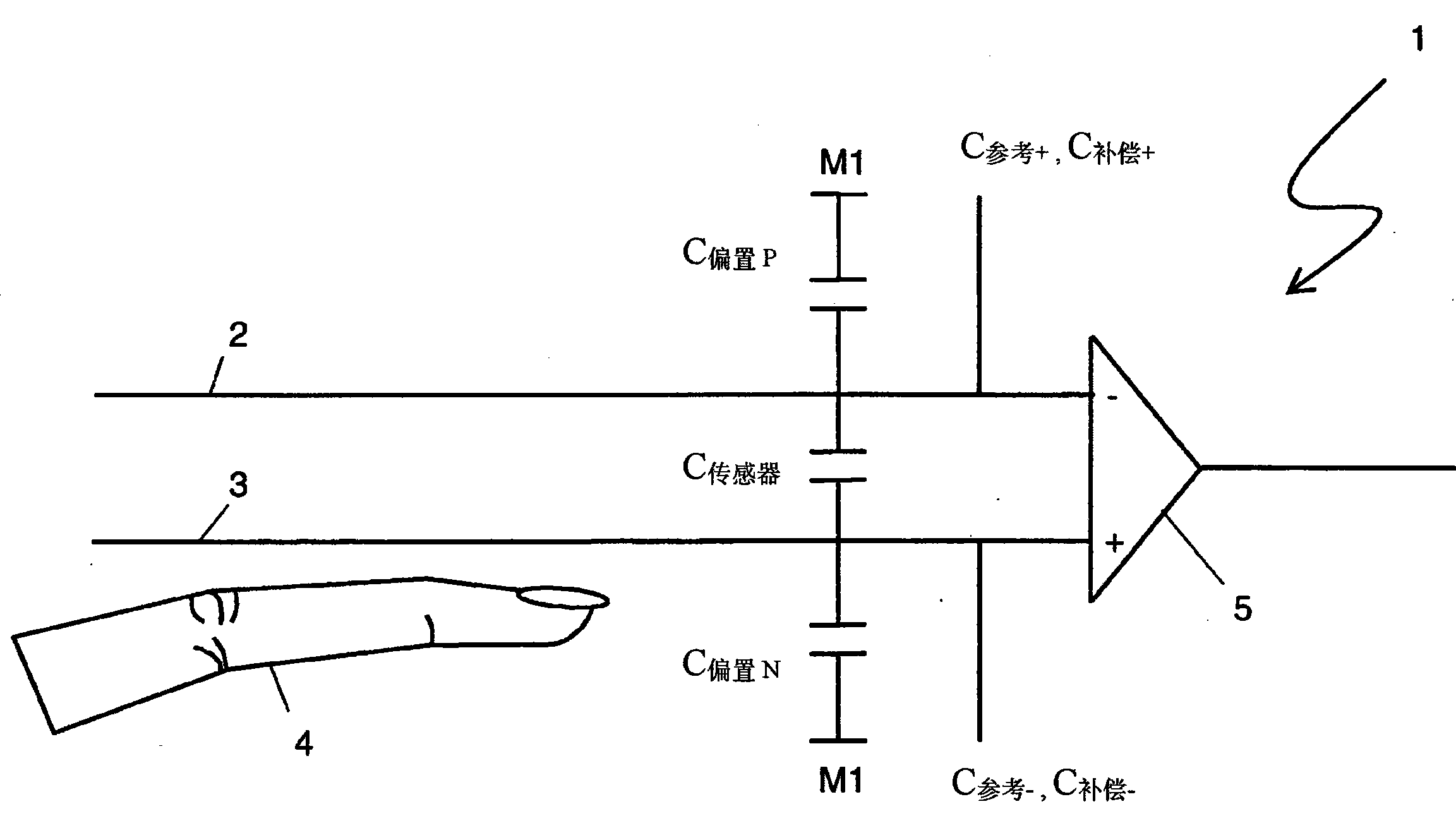

[0028] figure 1 The basic design of the capacitive automatic reversing device 1 of the present invention is shown. The two sensor electrodes - the first electrode 2 and the second electrode 3 - each consist of wires which are spaced apart and run parallel to each other along the edge of the seal of the door or window to be fastened thereto. The wires can be integrated in the sealing rubber of the window pane of the car door. The two electrodes 2, 3 form a capacitance C 传感器 . The parasitic capacitance with respect to ground M1 generated by the structure or its environment is defined as C 偏置P and C 偏置N . If an object, such as a finger 4, approaches the sensor device 1, the capacitance C 传感器 will change. The measurement of the capacitance or its change is carried out with the evaluation circuit 5 designed as an amplifier circuit, which is indicated by the symbol of an operational amplifier. The evaluation takes place in a known manner, eg by charge measurement or by time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com