Pneumatic button machine

A buttoning machine and pneumatic technology, applied in the field of buttoning machines, can solve the problems of no safety and aiming device, unable to accurately control the impulse force of buttoning and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

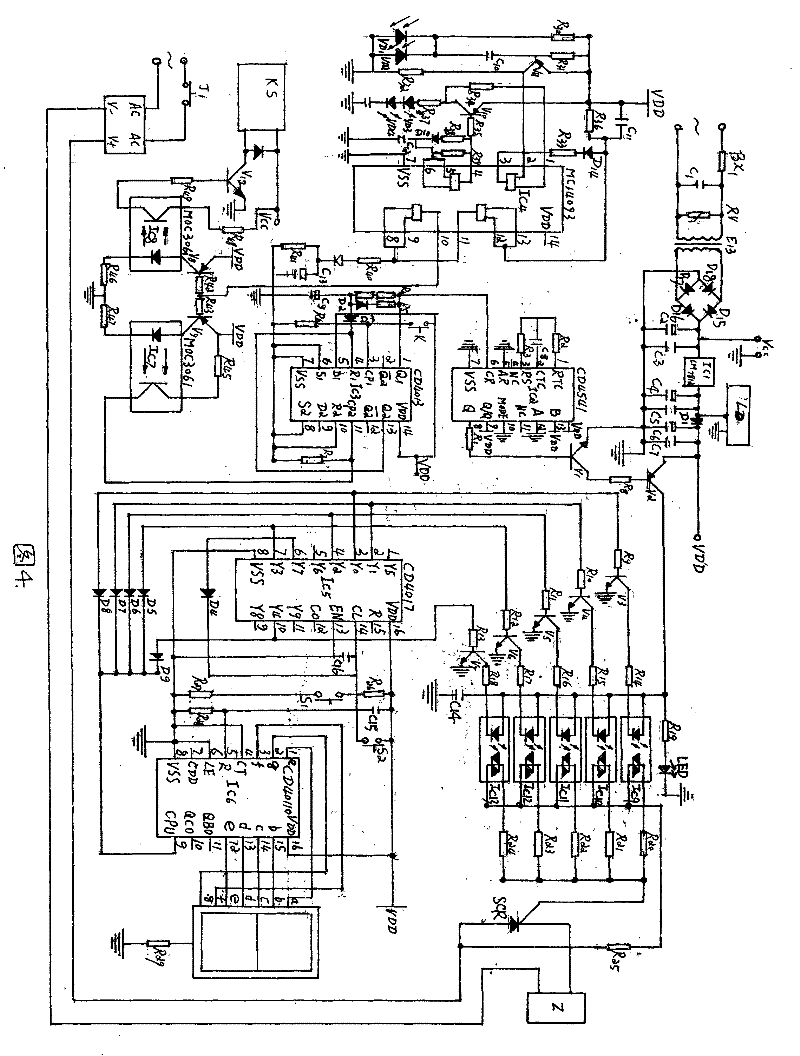

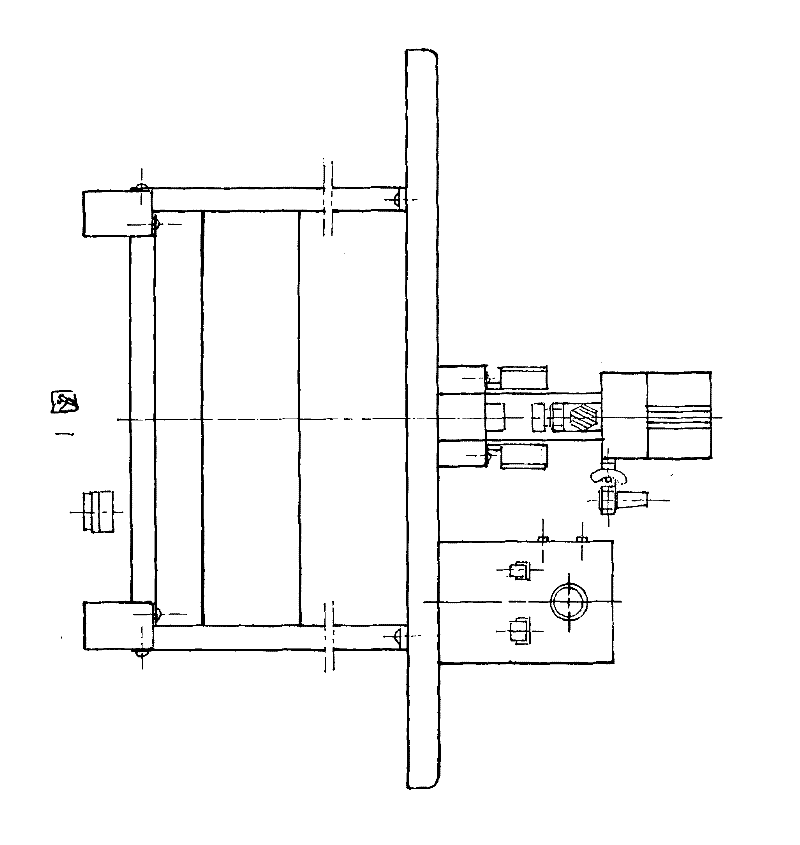

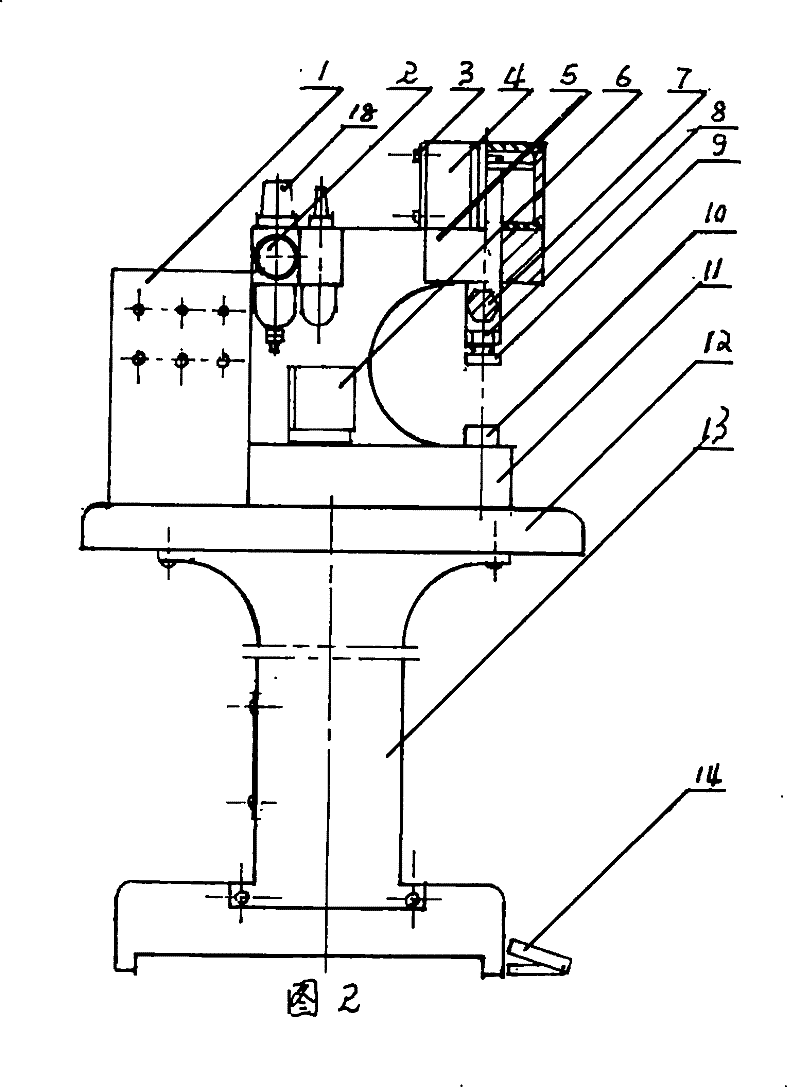

[0017] The pneumatic button sewing machine of the present invention is characterized in that: the body is installed on the platform, the support is fixedly connected with the platform by bolts, and the inner diameter of the cylinder is 8cm. 2cm, the cylinder is fixedly connected with the piston, and the solenoid valve is installed between the high-end air inlet and the low-end air inlet of the cylinder. Integrated Circuit I C1 to I C6 The models are LM7812, CD4541, CD4013, MC14093, CD4017 and CD40110, I C7 and I C8 Light corner model is 4N25, I C9 to I C13 The light corner model is MO3061.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com