Long-acting electric conduction nozzle

A conductive tip, long-term technology, applied in the field of conductive tips, can solve the problems of loose contact between the welding wire and the inner hole of the conductive tip, affecting the welding quality, irregular shaking, etc., to prevent short-circuit burning of the welding tip, and avoid excessive temperature rise , the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

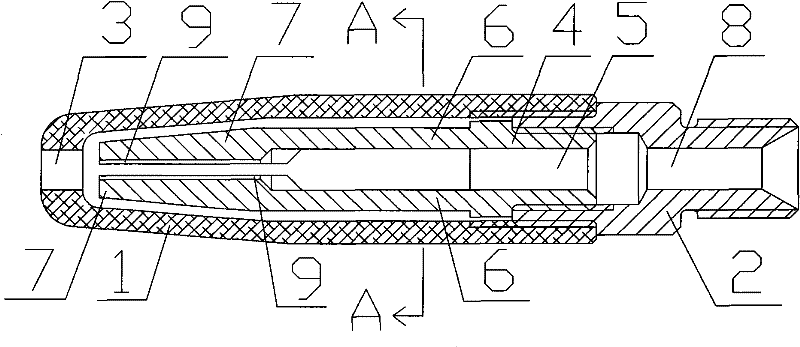

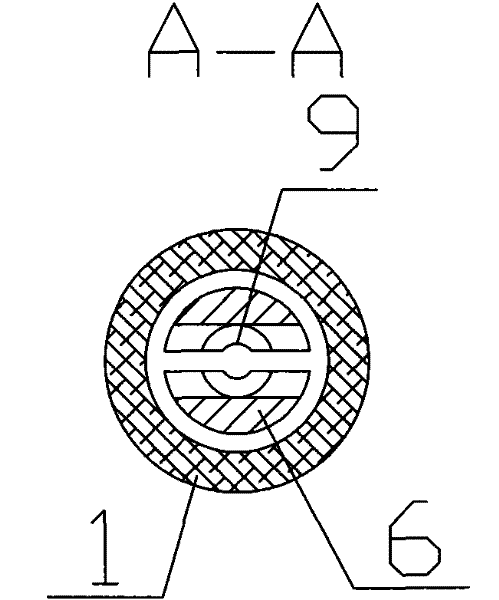

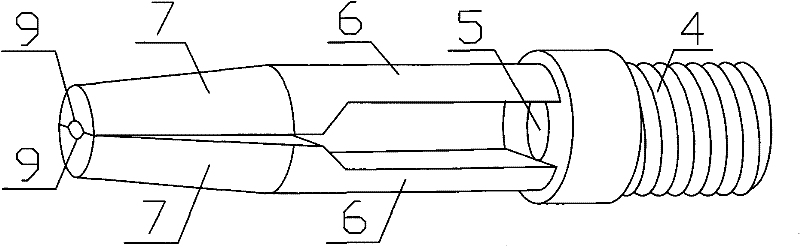

[0028] Such as figure 1 and figure 2 It shows an embodiment of the long-acting conductive tip of the present invention. The conductive tip is composed of a porcelain cap 1, a conductive inner core and a tailstock 2. The porcelain cap 1 is a hollow structure, and the center of the front end of the porcelain cap 1 is provided with a first Through hole 3, the conductive inner core is arranged in the porcelain cap 1, and the ceramic cap 1 is protected outside the conductive inner core. The front surface of the part 4 is connected with two symmetrically placed connecting pieces 6 which have elastic force themselves, and the front end of each connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com