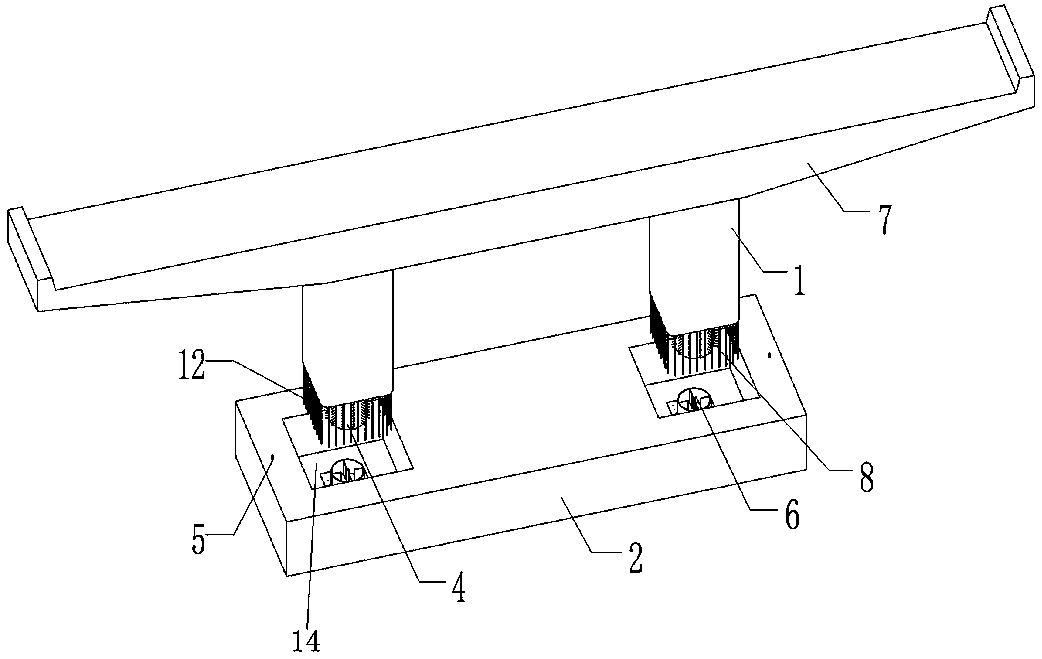

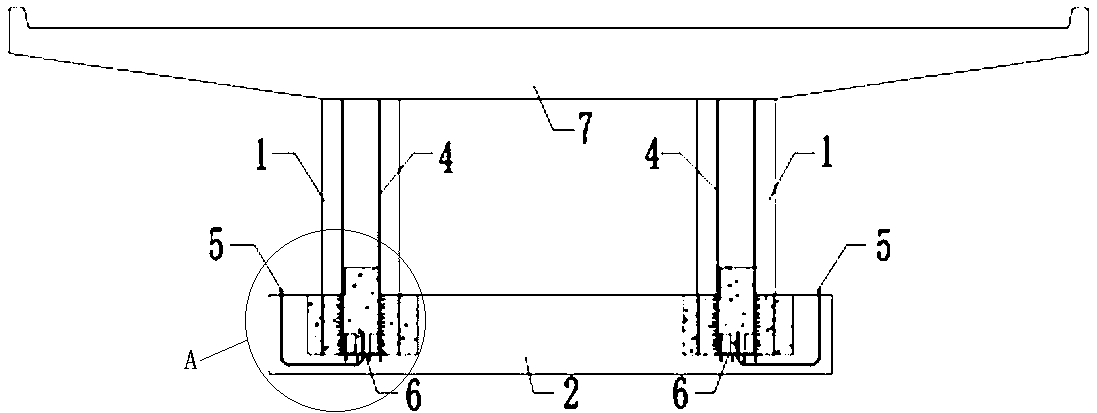

Prefabricated bridge pier and bearing platform connecting structure, construction method, prefabricated bridge pier and bearing platform

A technology for connecting structures and construction methods, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor shear resistance and earthquake resistance, achieve high shear bearing capacity and rigidity, reduce workload, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

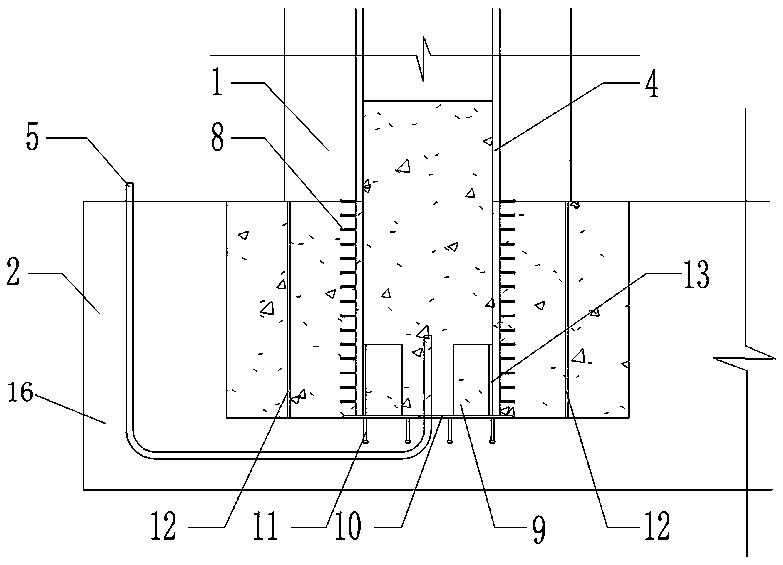

[0045] Embodiment 2, the difference between embodiment 2 and the above-mentioned embodiment 1 is that the pre-embedded steel pipe in the concrete structure of the pier is formed by a plug joint embedded in the bottom of the concrete pier, and the plug joint is used to connect with the pre-embedded plug in the pier cap. The part connected to the socket is a steel pipe structure, which is equivalent to the pre-embedded steel pipe in the prefabricated bridge crossing; during construction, the prefabricated pier is plugged into the pre-embedded socket in the pier cap through the plug joint at the bottom connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com