Device for detecting and conveying a plurality of materials and working method thereof

A technology of connecting shafts, which is used in the field of devices for detecting and conveying multiple materials, can solve the problems of high precision requirements, complex parts structure, and difficult processing, and achieve high detection sensitivity, simple part structure, and wide thickness range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

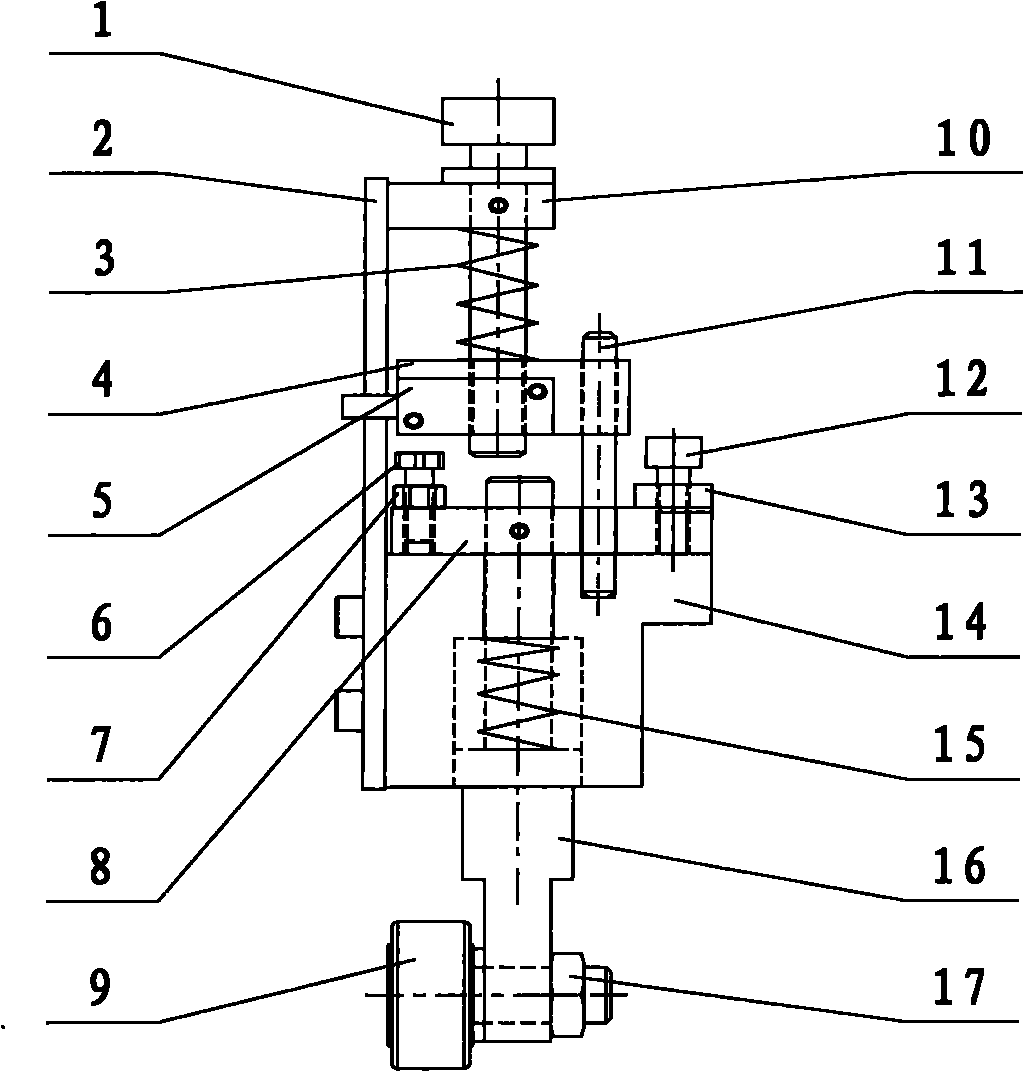

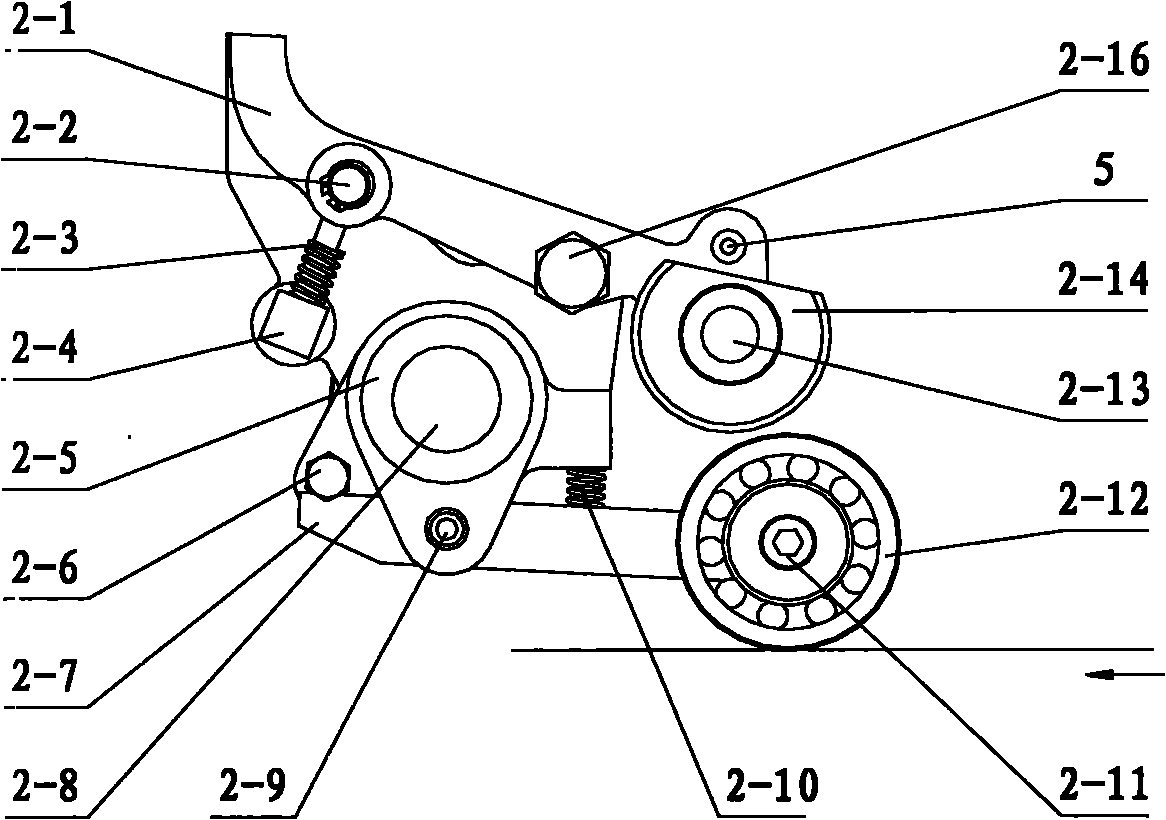

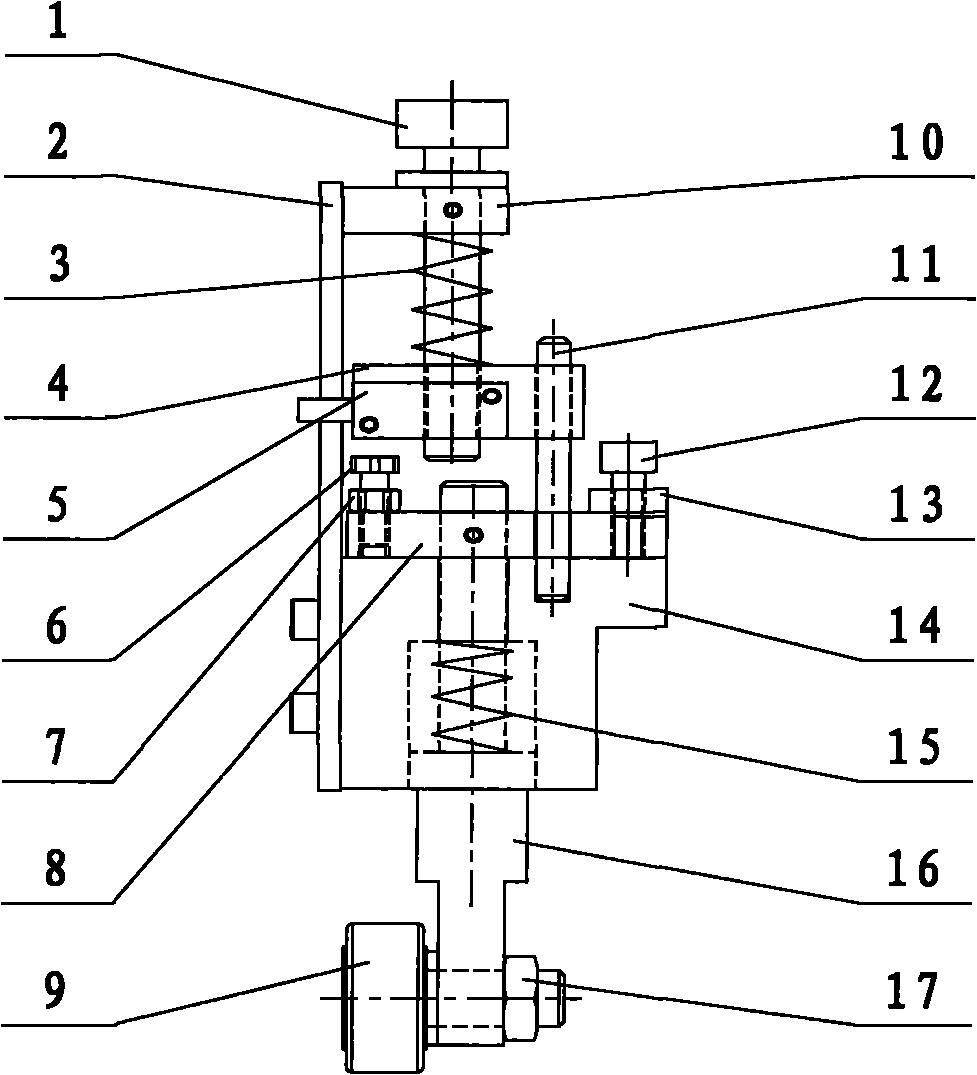

[0021] Embodiment: a kind of device that detects and conveys multiple sheets of material (see figure 1 ), characterized in that it consists of an adjustment rod 1, a connecting plate 2, a long spring 3, a fixed plate 4, a proximity switch 5, a positioning screw 6, a nut 7, an adjustment plate 8, a roller 9, a positioning plate 10, a guide 11, an adjustment Screw 12, adjusting nut 13, seat 14, elastic mechanism 15, connecting shaft 16 and locking nut 17 constitute; Said positioning plate 10 and seat 14 are fixedly connected to connecting plate 2 respectively; Said adjusting rod 1 passes positioning plate The via hole on the 10 is threadedly connected with the fixed plate 4, and the said long spring 3 is sleeved on the adjusting rod 1 and placed between the fixed plates 4 of the positioning plate 10; the said proximity switch 5 is fixedly connected with the fixed plate 4; Said adjusting plate 8 is placed above the seat 14; said positioning screw 6 is threadedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com