Adjusting and controlling mechanism for EGR rate

A technology for regulating control and valve nozzles, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of easy adsorption of coke particles, blocked valves, and many parts, etc., to improve reliability and service life, increase EGR rate, simple effect of part structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

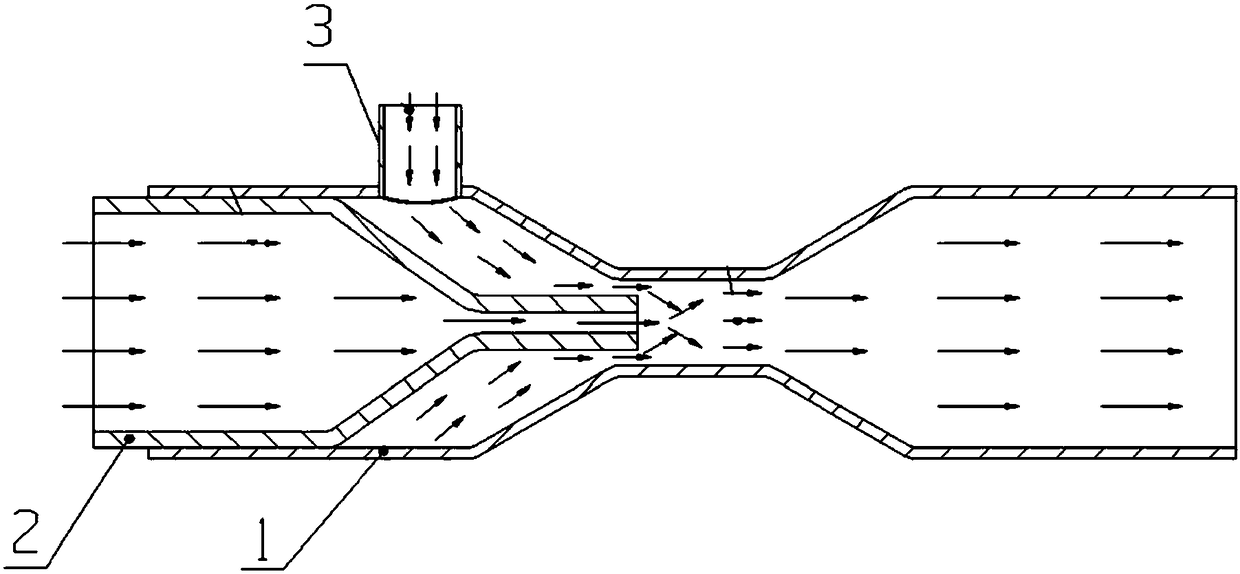

[0034] 1. After the air enters the Venturi tube through the air inlet 3, the Venturi effect is generated, and the exhaust gas can enter the intake tube at a lower pressure.

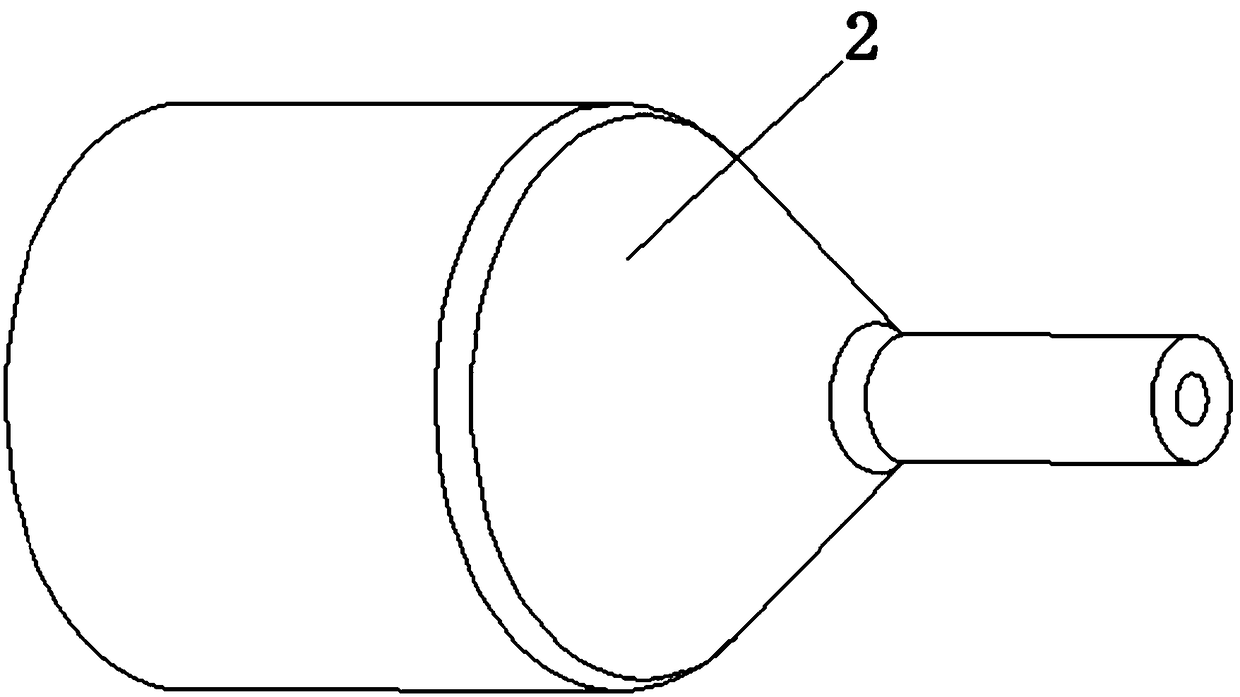

[0035] 2. Through the forward movement of the valve nozzle 2, the interception effect of the venturi can be controlled to achieve the interception of the intake air and further reduce the pressure in the middle of the venturi, thereby introducing more exhaust gas, thereby achieving a throttle similar to the current diesel engine Features.

[0036] 3. Through the backward movement of the valve nozzle 2, the pressure at the outlet of the valve nozzle is increased, thereby reducing the amount of exhaust gas introduced.

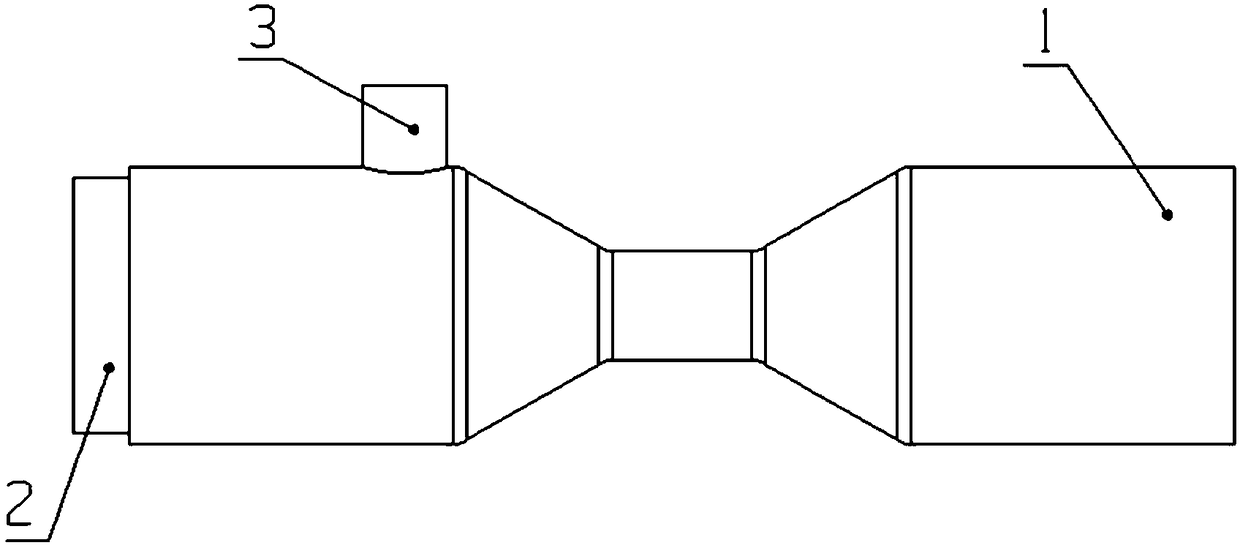

[0037] In summary, the EGR rate adjustment control mechanism realizes the function of EGR drainage by placing a valve nozzle mechanism in front of the venturi tube, and can translate left and right through the valve nozzle mechanism in front of the venturi tube, thereby achieving EGR rate control. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com