Preparation method of SiC-SiAlCN glass ceramics

A technology of glass-ceramic and manufacturing method, which is applied in the field of manufacturing non-oxide glass-ceramics by high-temperature pyrolysis of ceramic precursor polymer alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

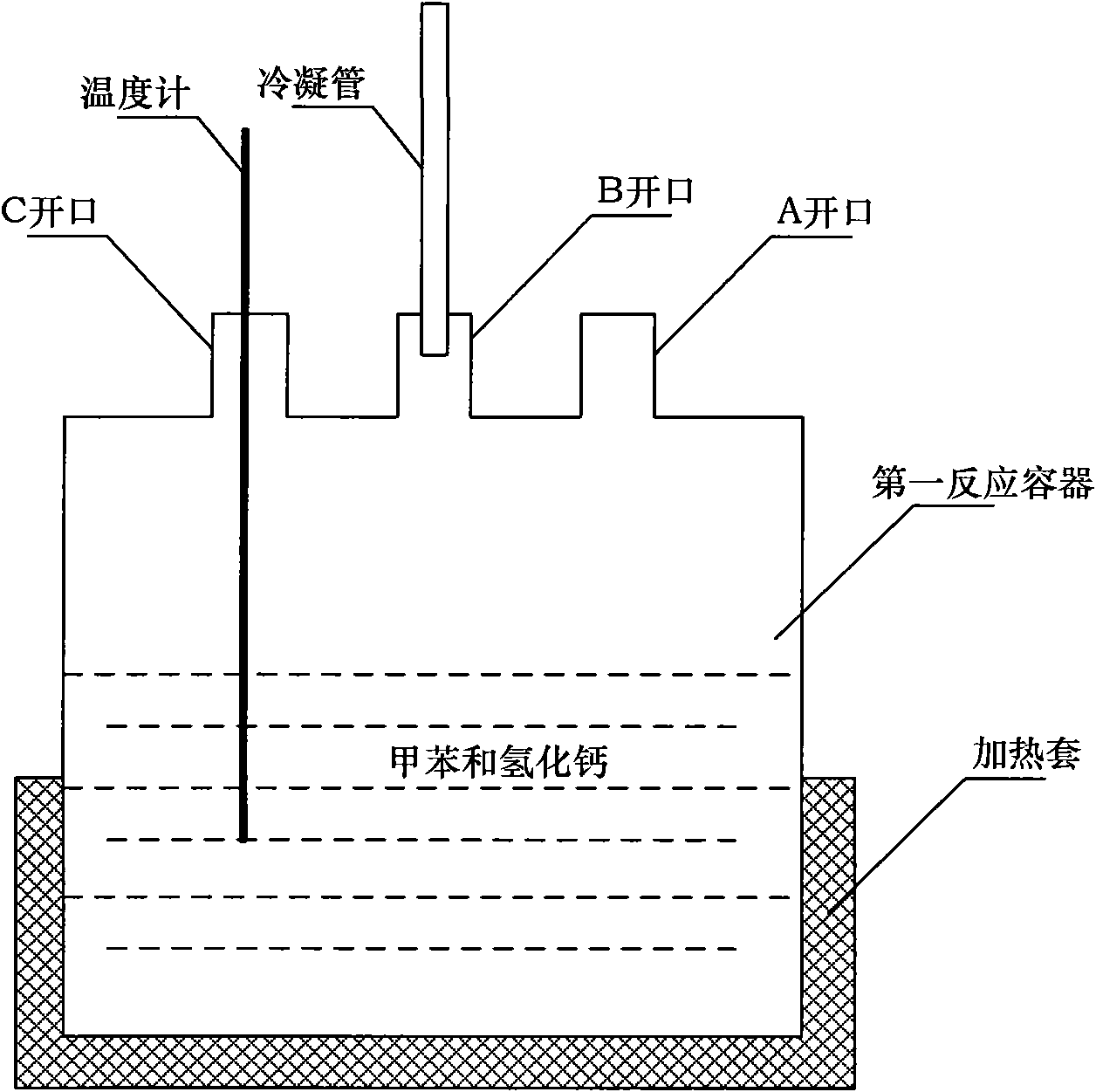

[0074] Step 1: Preparation of anhydrous toluene

[0075] Toluene C 6 H 6 and calcium hydride CaH 2 It is put into the first reaction vessel through the opening of A, refluxed at a temperature of 105°C (measured in real time by a thermometer) to remove trace water in toluene, and then distilled at 110°C (measured in real time by a thermometer) to obtain anhydrous. Toluene; add 5g of calcium hydride to 100ml of toluene;

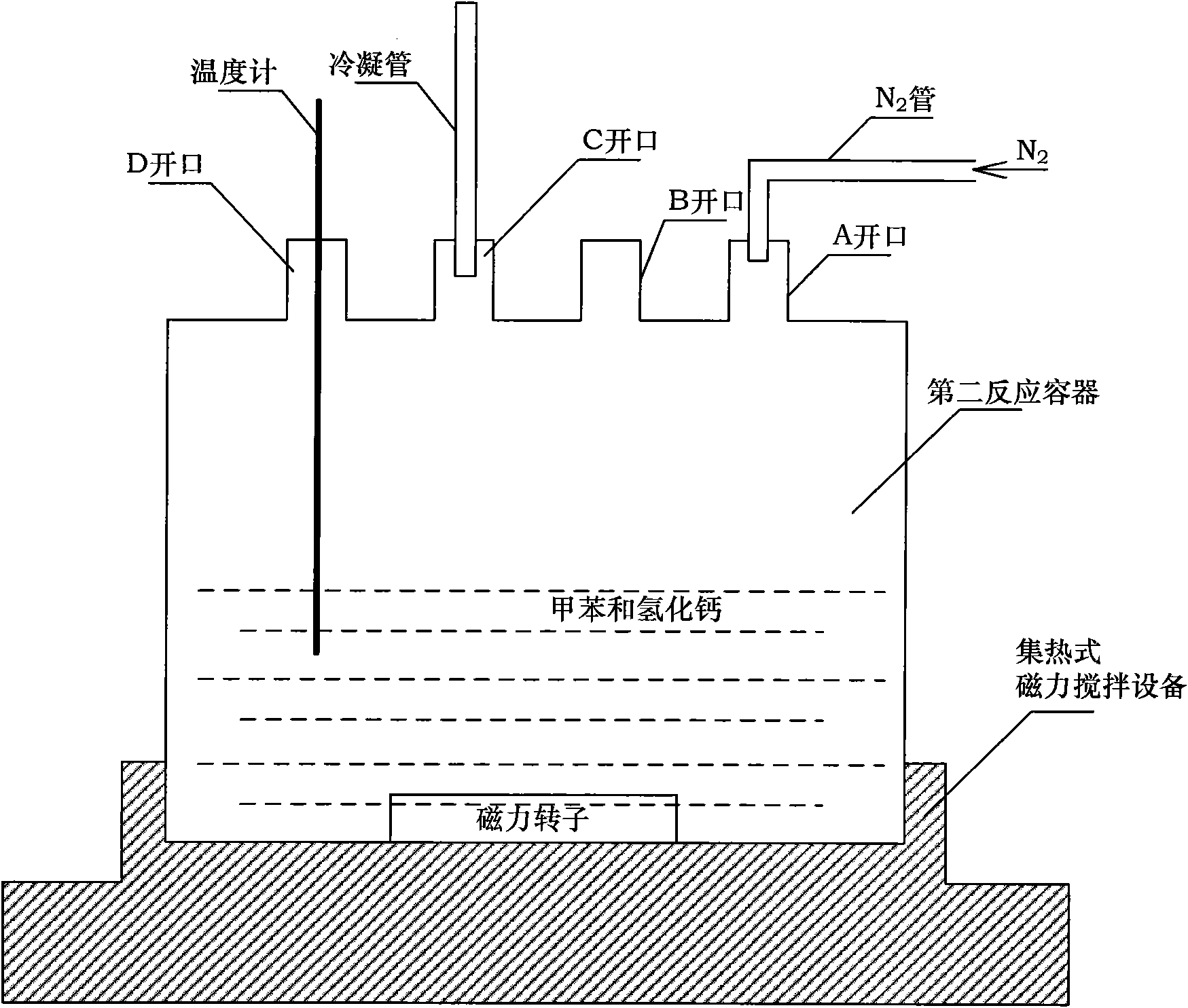

[0076] Step 2: Preparation of liquid polyaluminosilazane (PAS)

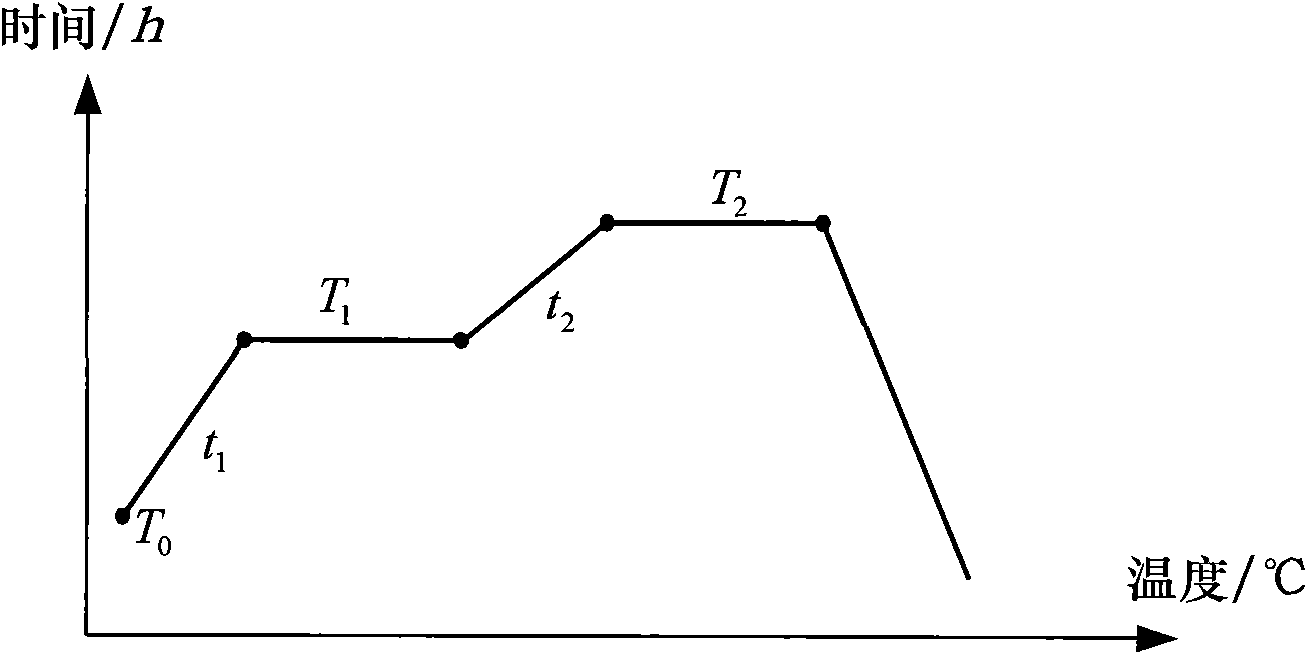

[0077] (A) Fill the second reaction vessel with N for 10min through the A opening 2 , N 2 The flow rate is 40ml / min; (B) the aluminum hydride and polysilazane are loaded into the second reaction vessel through the opening of B; (C) the rotating speed of the tetrafluoromagnetic rotor is adjusted to be 800r / min by the magnetic stirring device; (D) After stirring and reacting for 100 min at a temperature of 22 °C, the liquid polyaluminosilazane was obtained by stirring and reacting at a tempera...

Embodiment 2

[0094] Step 1: Preparation of anhydrous toluene

[0095] Toluene C 6 H 6 and calcium hydride CaH 2 It is put into the first reaction vessel through the opening of A, refluxed at a temperature of 108 ° C (measured in real time by a thermometer) to remove trace water in toluene, and then distilled at 112 ° C (measured in real time by a thermometer) to obtain anhydrous. Toluene; 10g of calcium hydride was added to 100ml of toluene;

[0096] Step 2: Preparation of liquid polyaluminosilazane (PAS)

[0097] (A) Fill the second reaction vessel with N for 5 min through the A opening 2 , N 2 The flow rate is 40ml / min; (B) trimethyl alane and polysilazane are loaded into the second reaction vessel through the B opening; (C) the rotating speed of the tetrafluoromagnetic rotor is regulated by magnetic stirring equipment to be 700r / min; (D) After stirring and reacting at a temperature of 20°C for 50 min, then stirring and reacting at a temperature of 40°C for 10 h to obtain a liquid ...

Embodiment 3

[0112] Step 1: Preparation of anhydrous toluene

[0113] Toluene C 6 H 6 and calcium hydride CaH 2 It is put into the first reaction vessel through the opening of A, refluxed at a temperature of 110 ° C (measured in real time by a thermometer) to remove trace water in toluene, and then distilled at 112 ° C (measured in real time by a thermometer) to obtain anhydrous. Toluene; 1g of calcium hydride was added to 100ml of toluene;

[0114] Step 2: Preparation of liquid polyaluminosilazane (PAS)

[0115] (A) Fill the second reaction vessel with N for 10min through the A opening 2 , N 2 The flow rate is 30ml / min; (B) the metal aluminum organic matter and polysilazane are loaded into the second reaction vessel through the opening of B; (C) the rotating speed of the tetrafluoromagnetic rotor is adjusted by a magnetic stirring device to be 600r / min; (D) ) After stirring and reacting for 150 min at a temperature of 25 °C, and then stirring and reacting at a temperature of 45 °C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com