Pickering super emulsifier silicon dioxide nano net and preparation method thereof

A silicon dioxide and emulsifier technology, applied in the direction of silicon dioxide, silicon oxide, etc., to achieve the effects of adjustable and controllable structure and size, simple preparation method, and wide composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

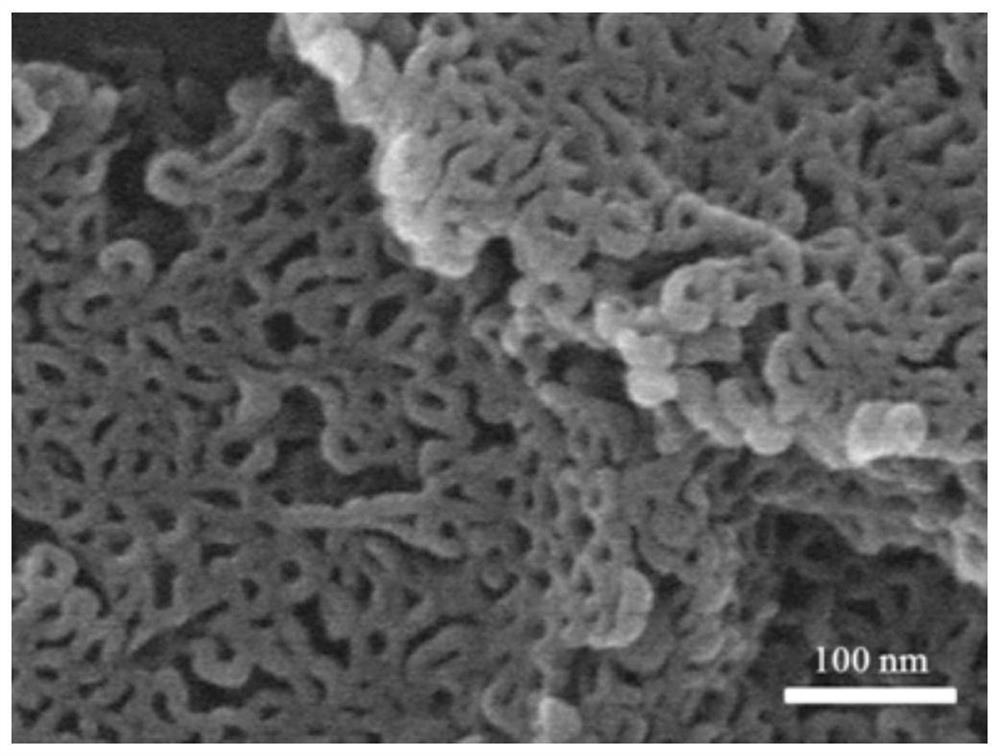

[0033] Dissolve 2.5 g of the sodium salt hydrolyzate of styrene-maleic anhydride copolymer in 100 mL of water, and mix well. The pH value of the above solution was adjusted to 10 with 25% concentrated ammonia water, and the solution was placed in a 50° C. water bath. A mixed solution of 4.0 g of methyl orthosilicate and 20 g of toluene was added to the above aqueous solution for homogeneous emulsification at a homogenization speed of 20,000 rpm, emulsification time of 5 min, and constant temperature reaction at 50°C for 12 h. The reaction system was cooled to room temperature, and silica nanonets were obtained after suction filtration, washing, drying and crushing. The scanning electron microscope photos of the silica nanonets are shown in figure 1 . The obtained silica nanonets were washed with deionized water and ethanol repeatedly by centrifugation or calcined at 400° C.-500° C. to remove the template agent. Mix 5mL water, 5mL decane, and 1wt% silica nanomesh, and vortex ...

Embodiment 2

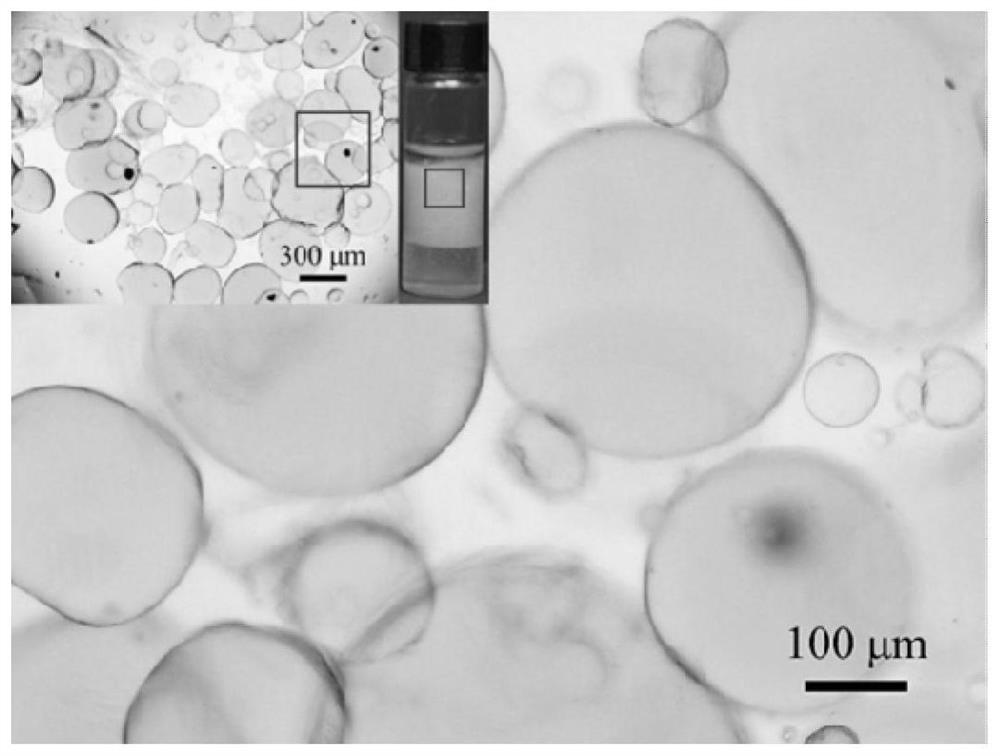

[0035] Dissolve 2.5g of sodium lauryl sulfate in 100mL of water and mix well. The pH value of the above solution was adjusted to 2.5 with 2 mol / L hydrochloric acid, and the solution was placed in a 50°C water bath. A mixed solution of 4.0 g of tetraethyl orthosilicate and 20 g of paraffin wax was added to the above aqueous solution for homogeneous emulsification at a homogenization speed of 20,000 rpm, emulsification time of 5 min, and constant temperature reaction at 50° C. for 12 h. The reaction system was cooled to room temperature, and the silica nanonet was obtained after suction filtration, washing, drying and crushing. The obtained silica nanonets were washed with deionized water and ethanol repeatedly by centrifugation or calcined at 400° C.-500° C. to remove the template agent. Mix 5 mL of water, 5 mL of imidazolium hexafluorophosphorus ionic liquid, and 2 wt % silica nanonets, and form an emulsion after vortexing. The micrograph of the emulsion is shown in image ...

Embodiment 3

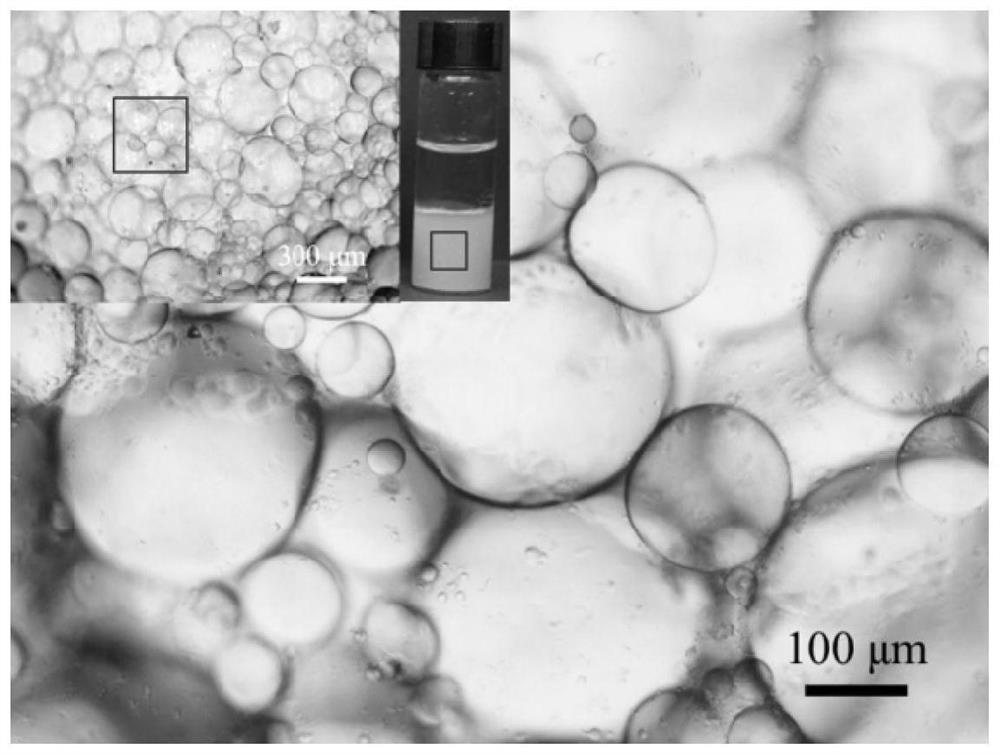

[0037] Dissolve 2.5g of sodium polyvinylbenzenesulfonate in 100mL of water and mix well. The pH value of the above solution was adjusted to 10 with 25% concentrated ammonia water, and the solution was placed in a 50° C. water bath. Add a mixed solution of 20g carbon tetrachloride dissolved in 4.0g N-phenyl-3-aminopropyltrimethoxysilane to the above aqueous solution, homogeneously emulsify, homogeneous speed 20000rpm, emulsification time 5min, 50 ℃ constant temperature reaction 12h. The reaction system was cooled to room temperature, and the silica nanonet was obtained after suction filtration, washing, drying and crushing. The obtained silica nanonets were washed with deionized water and ethanol repeatedly by centrifugation or calcined at 400° C.-500° C. to remove the template agent. Mix 5mL amyl alcohol, 5mL hexafluorophosphoimidazolium ionic liquid, and 3wt% silica nanonets, and vortex to form an emulsion. The micrograph of the emulsion is shown in Figure 4 , is an alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com