Manufacturing method of SiC-SiBCN nucleated glass

A kind of glass-ceramic and a technology of manufacturing method, which are applied in the field of manufacturing SiC-SiBCN glass-ceramic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

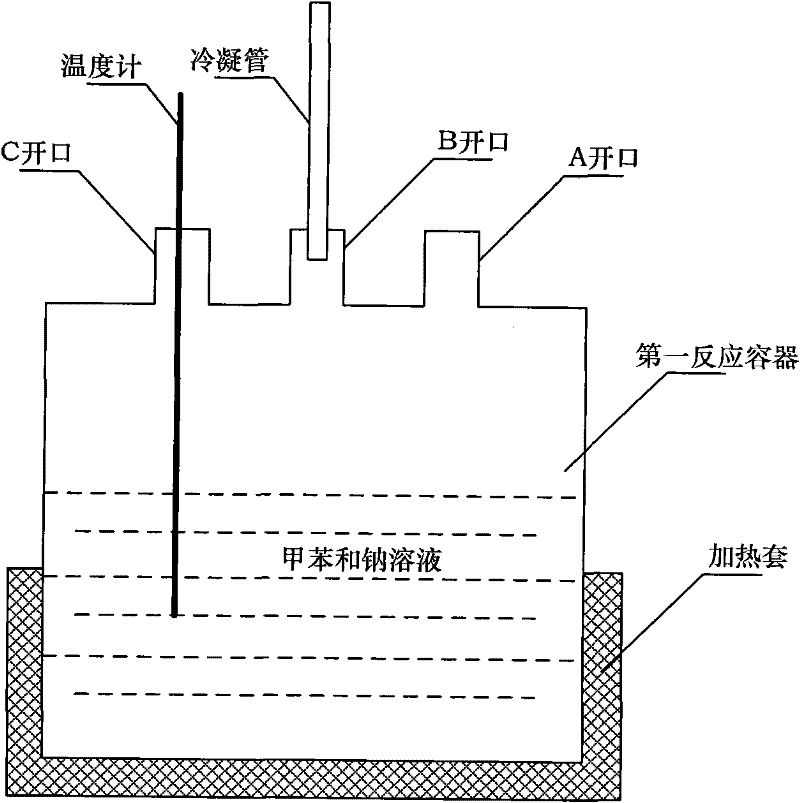

[0057] Step 1: Prepare anhydrous toluene

[0058] Toluene C 6 H 6 The sodium and Na are put into the first reaction vessel through the opening A, reflux at 110℃ (measured by the thermometer in real time) to remove trace water in toluene, and then distilled at 112℃ (measured by the thermometer in real time) Obtain anhydrous toluene; add 5g of sodium to 100ml of toluene;

[0059] Step 2: Preparation of PCS-toluene solution

[0060] Dissolve polycarbosilane (PCS) in the anhydrous toluene prepared in step 1 to form a PCS-toluene solution; add 1g of polycarbosilane to 1ml of anhydrous toluene;

[0061] Step 3: Prepare PBS-toluene solution

[0062] Dissolve polyborosilazane (PBS) in the anhydrous toluene prepared in step 1 to form a PBS-toluene solution; add 1ml of polyborosilazane (PBS) to 1ml of anhydrous toluene;

[0063] Step 4: Precursor polymer alloy

[0064] The PCS-toluene solution prepared in step 2 and the PBS-toluene solution prepared in step 3 were mixed at a magnetic stirring spee...

Embodiment 2

[0074] Step 1: Prepare anhydrous toluene

[0075] Toluene C 6 H 6 And sodium Na is put into the first reaction vessel through opening A, refluxed at 108℃ (measured by thermometer in real time) to remove trace water in toluene, and then distilled at 112℃ (measured by thermometer in real time) Obtain anhydrous toluene; add 3g of sodium to 100ml of toluene;

[0076] Step 2: Preparation of PCS-toluene solution

[0077] Dissolve polycarbosilane (PCS) in the anhydrous toluene prepared in step 1 to form a PCS-toluene solution; add 0.5 g of polycarbosilane to 1 ml of anhydrous toluene;

[0078] Step 3: Prepare PBS-toluene solution

[0079] Dissolve polyborosilazane (PBS) in the anhydrous toluene prepared in step 1 to form a PBS-toluene solution; add 0.5 ml of polyborosilazane (PBS) to 1 ml of anhydrous toluene;

[0080] Step 4: Precursor polymer alloy

[0081] The PCS-toluene solution prepared in step 2 and the PBS-toluene solution prepared in step 3 were mixed at a magnetic stirring speed of 60...

Embodiment 3

[0089] Step 1: Prepare anhydrous toluene

[0090] Toluene C 6 H 6 And sodium Na is put into the first reaction vessel through opening A, and refluxed at 105℃ (measured by thermometer in real time) to remove trace water in toluene, and then distilled at 110℃ (measured by thermometer in real time) Obtain anhydrous toluene; add 1g of sodium to 100ml of toluene;

[0091] Step 2: Preparation of PCS-toluene solution

[0092] Dissolve polycarbosilane (PCS) in the anhydrous toluene prepared in step 1 to form a PCS-toluene solution; add 0.1 g of polycarbosilane to 1 ml of anhydrous toluene;

[0093] Step 3: Prepare PBS-toluene solution

[0094] Dissolve polyborosilazane (PBS) in the anhydrous toluene prepared in step 1 to form a PBS-toluene solution; add 0.1 ml of polyborosilazane (PBS) to 1 ml of anhydrous toluene;

[0095] Step 4: Precursor polymer alloy

[0096] The PCS-toluene solution prepared in step 2 and the PBS-toluene solution prepared in step 3 were mixed at a magnetic stirring speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com