Cooling structure for hot water recycle pump

A technology of hot water circulation pump and cooling structure, which is applied to parts, pumps, pump components, etc. of the pumping device used for elastic fluid, and can solve the problem of affecting the service life and performance of the motor, the motor cannot be effectively cooled, and the motor is heat-resistant Improve the cooling effect, improve the heat resistance, improve the service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

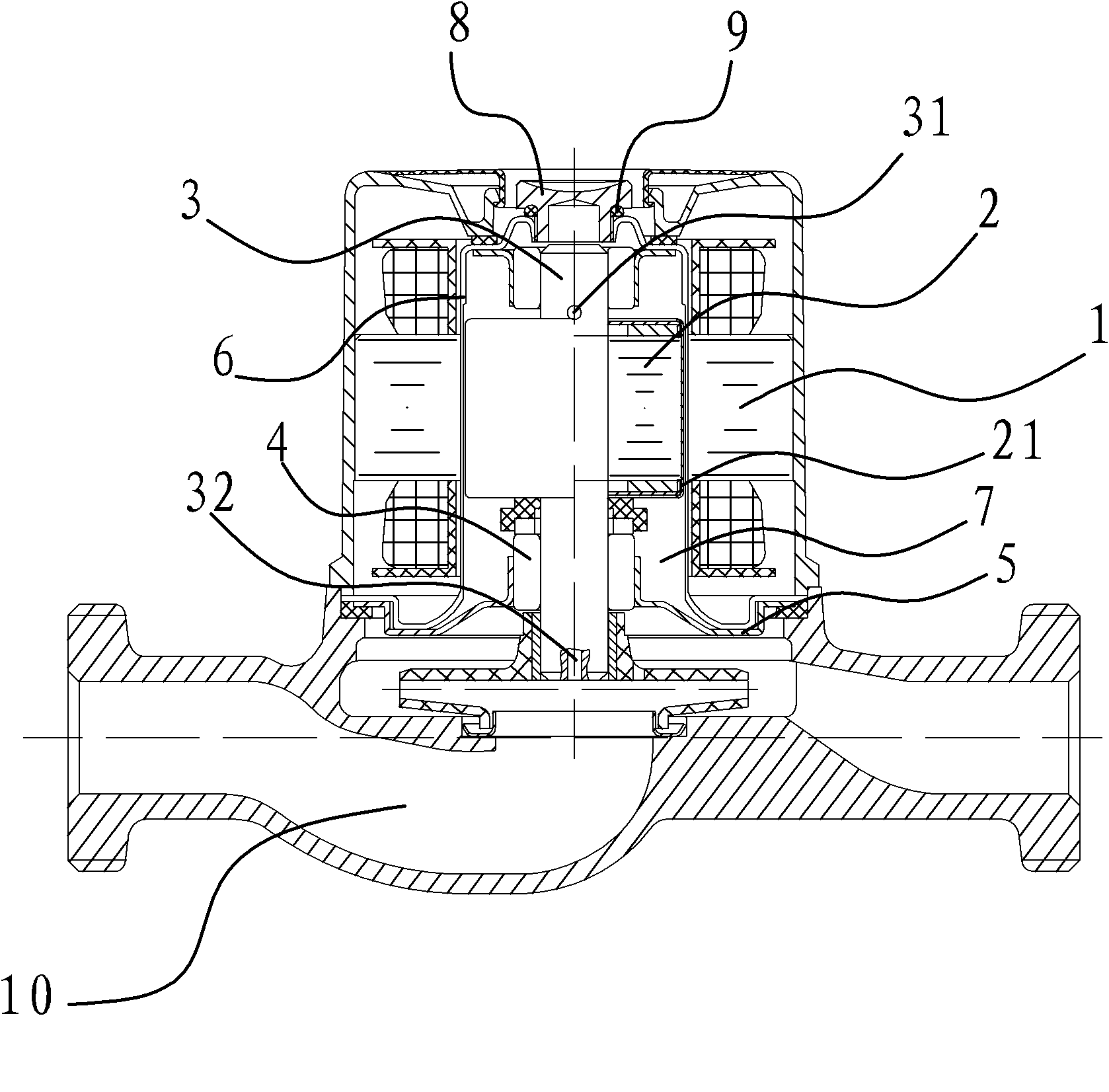

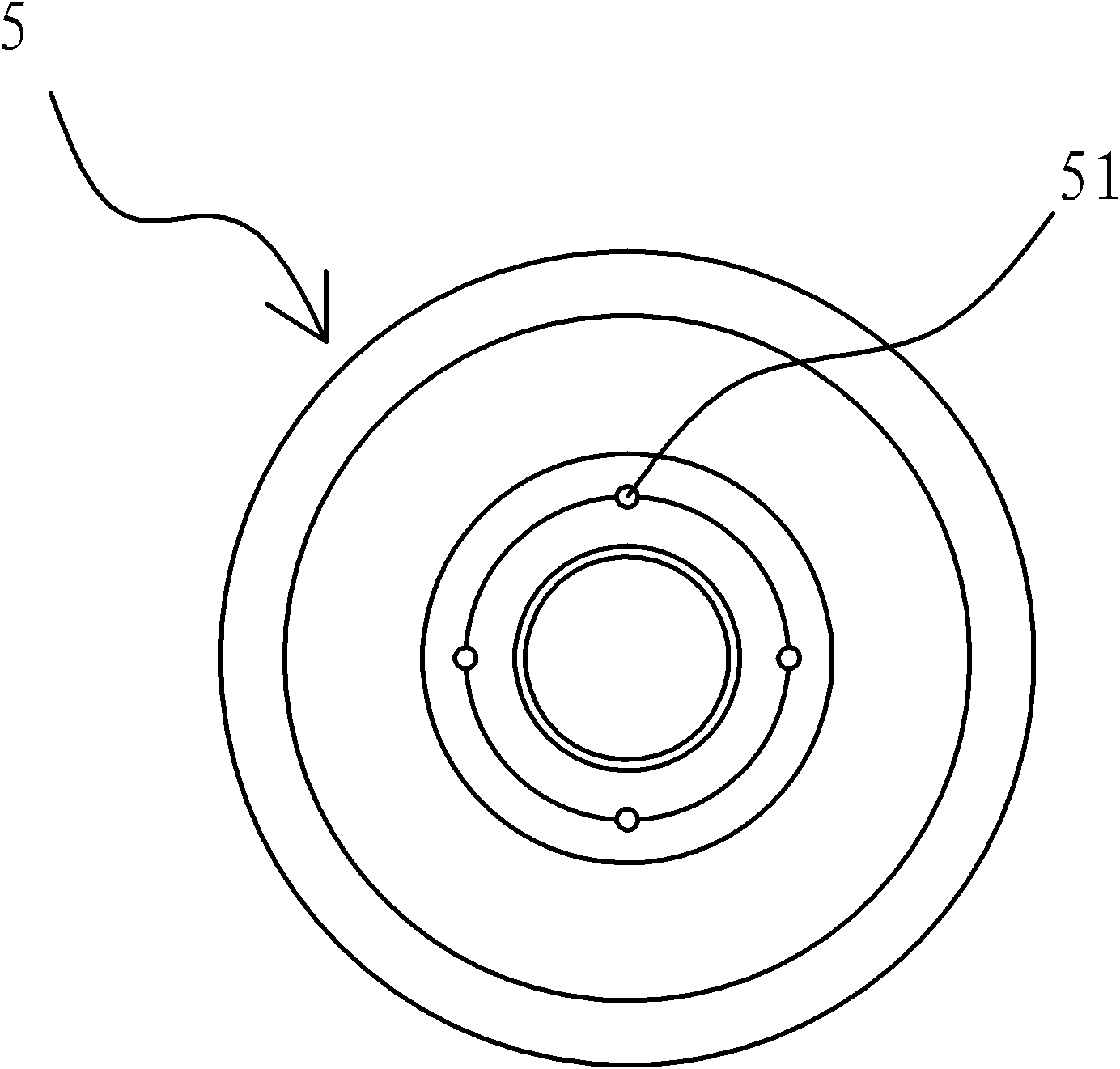

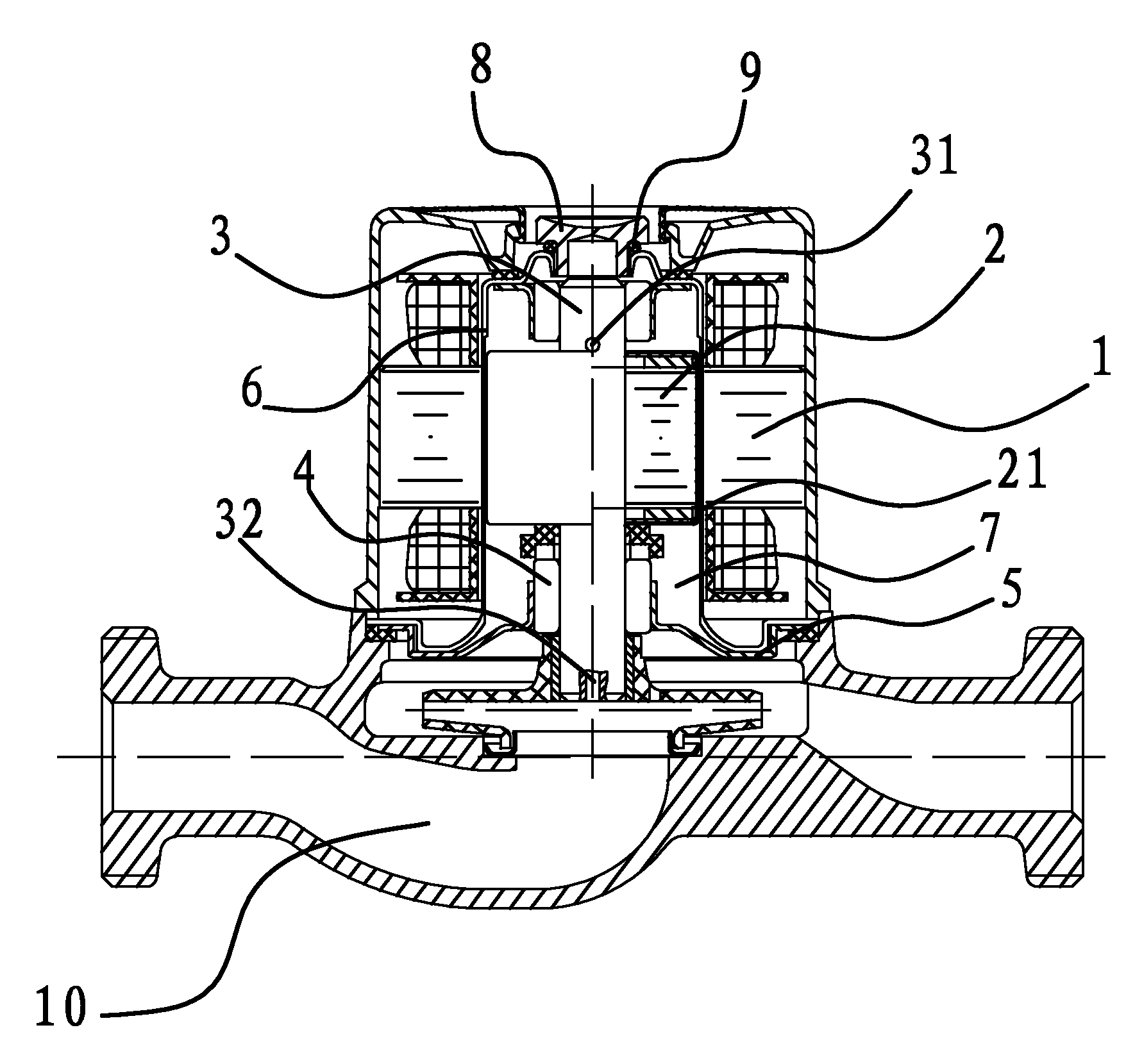

[0024] like figure 1 As shown, the cooling structure of the hot water circulating pump is set in the hot water circulating pump. The hot water circulating pump includes a stator 1, a rotor shaft 3, a rotor 2 and a bearing cover 5 fixedly sleeved on the rotor shaft 3, and the outer surface of the rotor 2 The side is covered with a protective sleeve 21 made of stainless steel, and the two ends of the rotor shaft 3 are sleeved with sliding bearings 4 made of antimony impregnated graphite. The cooling structure includes a cylindrical shielding sleeve 6 located between the rotor 2 and the stator 1, the shielding sleeve 6 is made of Hastelloy-c material, and an air release screw 8 is arranged between one end of the shielding sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com