Method and device for testing heat exchange capability of heat exchanger

A technology of heat exchanger and heat exchange capacity, which is applied in the field of test method and device for heat exchange capacity of heat exchanger, which can solve the problems of large error in test data, inability to control air volume correctly, poor operability, etc., and achieve test data reliable and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

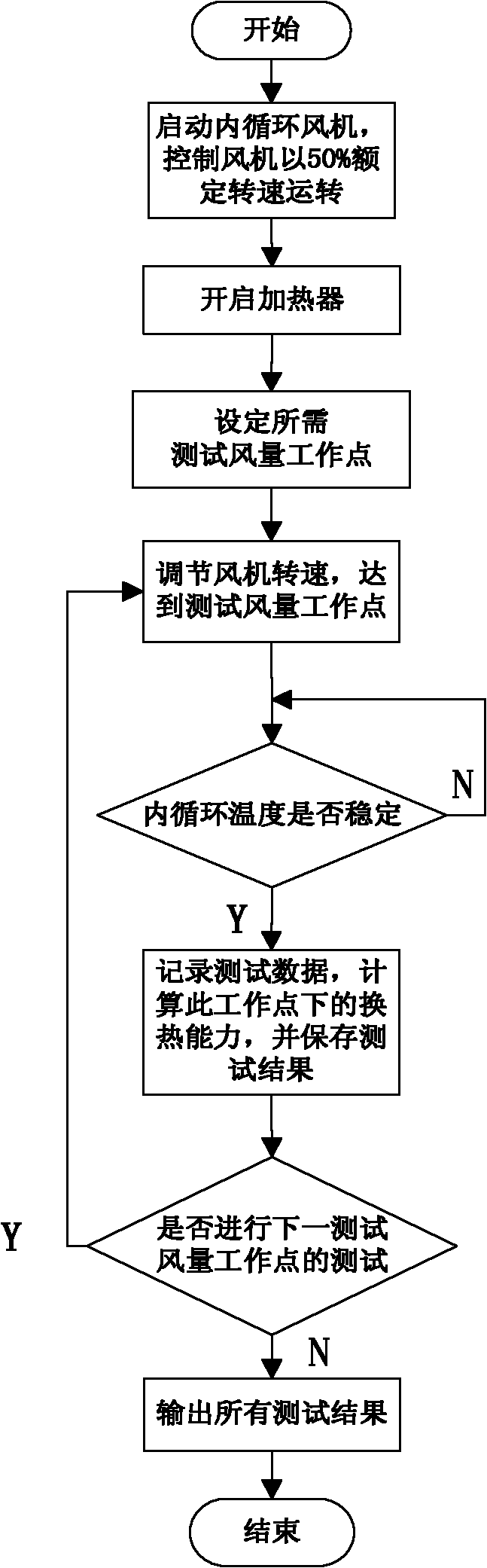

[0043] Embodiment 1, as figure 1 Shown is a flow chart of the method of the present invention, and this embodiment describes in detail the specific content and steps of the testing method according to the flow chart.

[0044] 1. Construct a simulated internal circulation system reflecting the internal circulation state of the heat exchanger and a simulated external circulation system reflecting the external circulation state of the heat exchanger. Connect the simulated internal circulation system to the inlet and outlet of the internal circulation of the heat exchanger, and simulate the external circulation The system is connected to the inlet and outlet of the external circulation of the heat exchanger;

[0045] 2. First start the fan in the simulated internal circulation system, and control the fan in the simulated internal circulation system to run at a certain speed by controlling the frequency converter. In this embodiment, the fan is controlled to run at 50% of the rated...

Embodiment 2

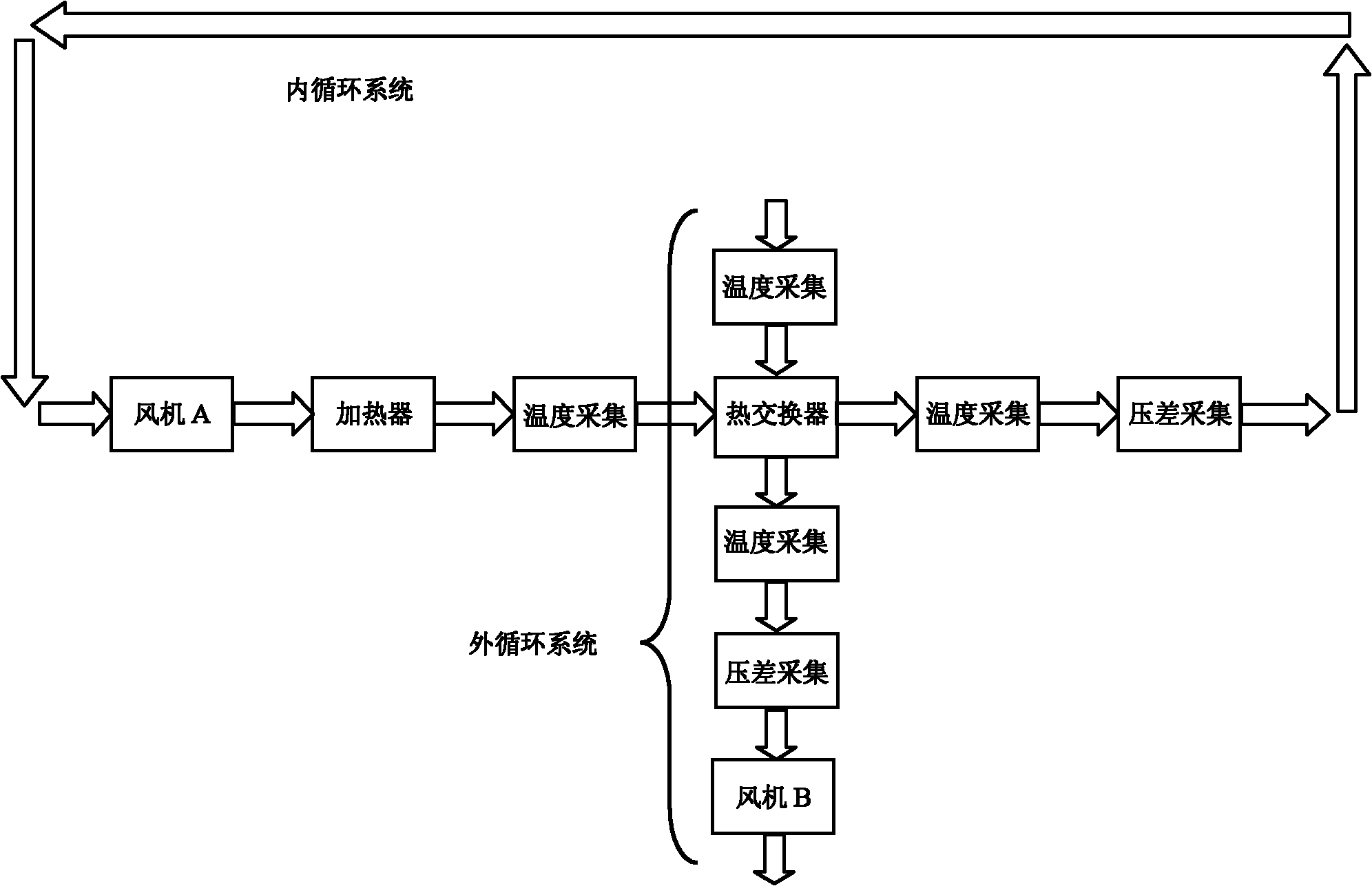

[0054] Embodiment 2, a test device for the heat exchange capacity of a heat exchanger, which mainly includes a simulated internal circulation system for simulating the internal circulation state of the heat exchanger, and a simulated external circulation system for simulating the external circulation state of the heat exchanger, The device also includes a main control mechanism, which is connected to and controls the temperature collection mechanism, the pressure difference collection mechanism, the heating mechanism and the air supply mechanism.

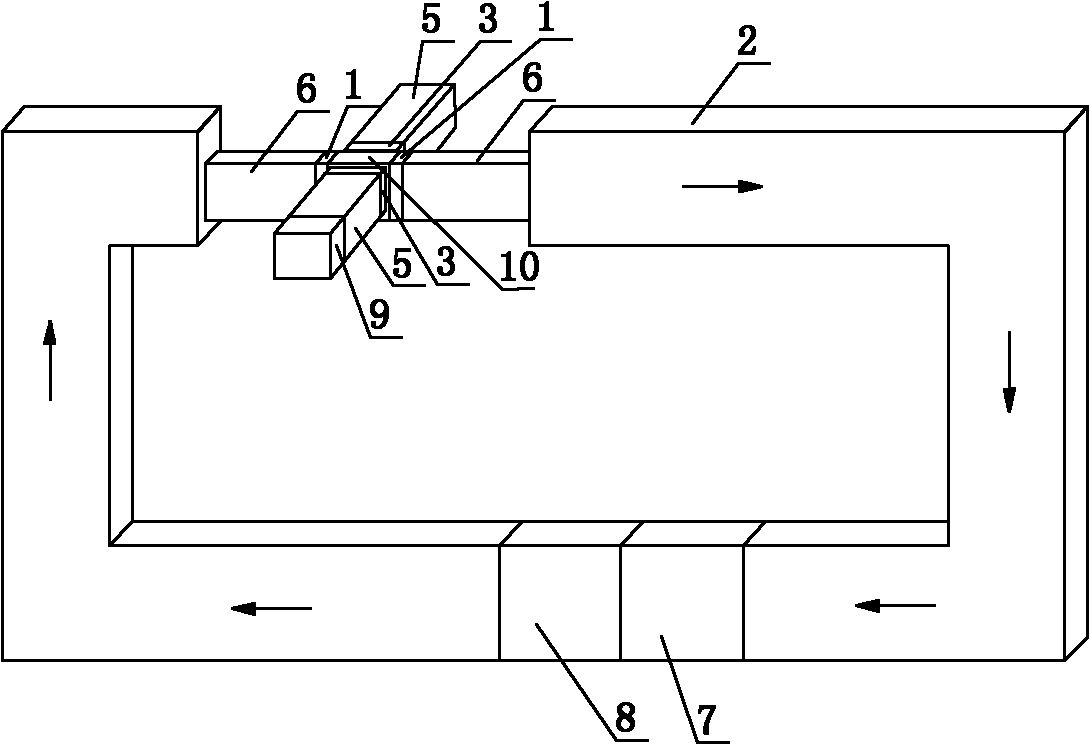

[0055] Such as figure 2 , 3 As shown, the simulated internal circulation system includes an internal circulation interface pipe 1 and an internal circulation air duct 2 that are connected together to form a closed circulation channel, and the internal circulation air duct 2 is provided with a valve for forming air flow in the internal circulation air duct 2. The air supply mechanism 7, the heating mechanism 8 for heating the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com