Composite paraboloid solar collector

A compound paraboloid and collector technology, which is applied to solar collectors, solar collectors using working fluid, heating devices, etc., can solve the problems of high initial cost, high failure rate of vacuum tubes, vacuum leakage, etc., and achieve thermal insulation. Good function, reducing heat dissipation and effective absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

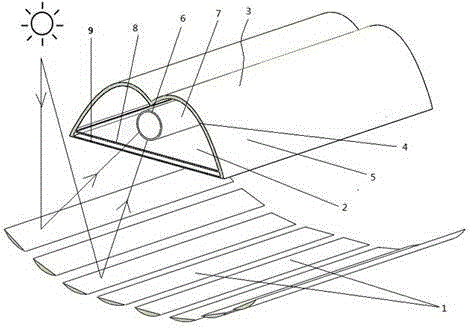

[0020] See attached figure 1 , the compound parabolic heat collector of the present invention includes a Fresnel reflection concentrating array 1, a cavity 2, a heat collector 3, a thermal insulation protection layer 4, a secondary reflection mirror 5, an absorption coating 6, a heat collection tube 7, an inner Glass surface 8, outer glass surface 9.

[0021] The heat collector 3 cooperates with the linear Fresnel reflection concentrator array 1 to form a solar focusing reflection system, and the independently fixed heat collector 3 constitutes an energy absorption system, and the outer wall of the heat collection tube 7 absorbing device is coated with a selective absorption coating 6, The heat collector 3 is composed of an inner glass surface 8 and an outer glass surface 9. The lower wall double-layer glass surface and the upper wall surface thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com